Electrode wire tightness adjustment mechanism for electrical spark linear incising machine tool

A cutting machine, EDM wire technology, applied in electrode manufacturing, electric processing equipment, metal processing equipment and other directions, can solve the problem that the EDM machine tool can not be truly constant tension, and achieve constant tension, not easy Vibration-causing and vibration-resistant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

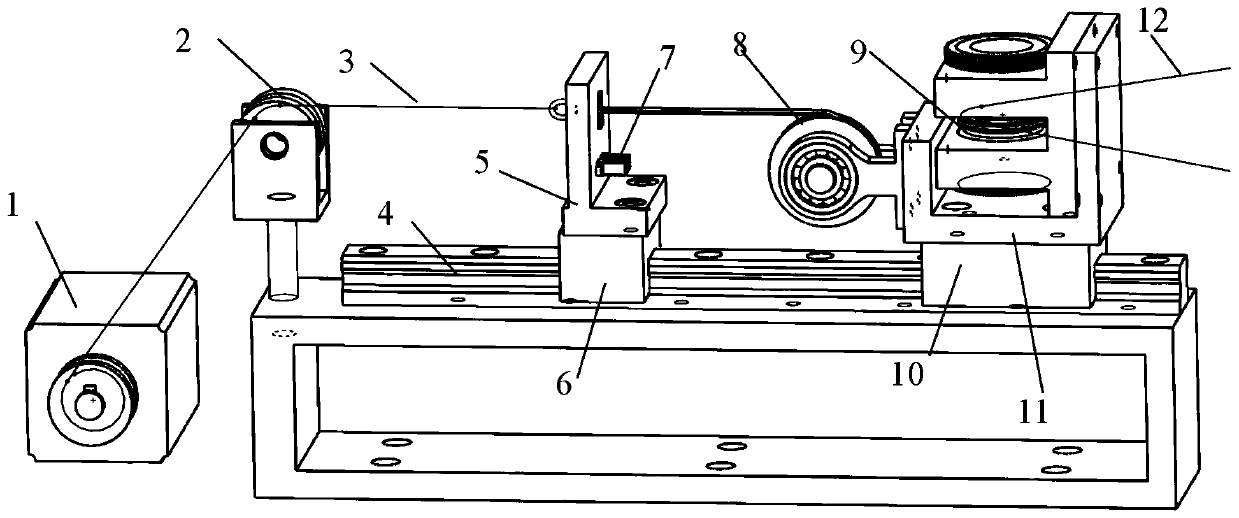

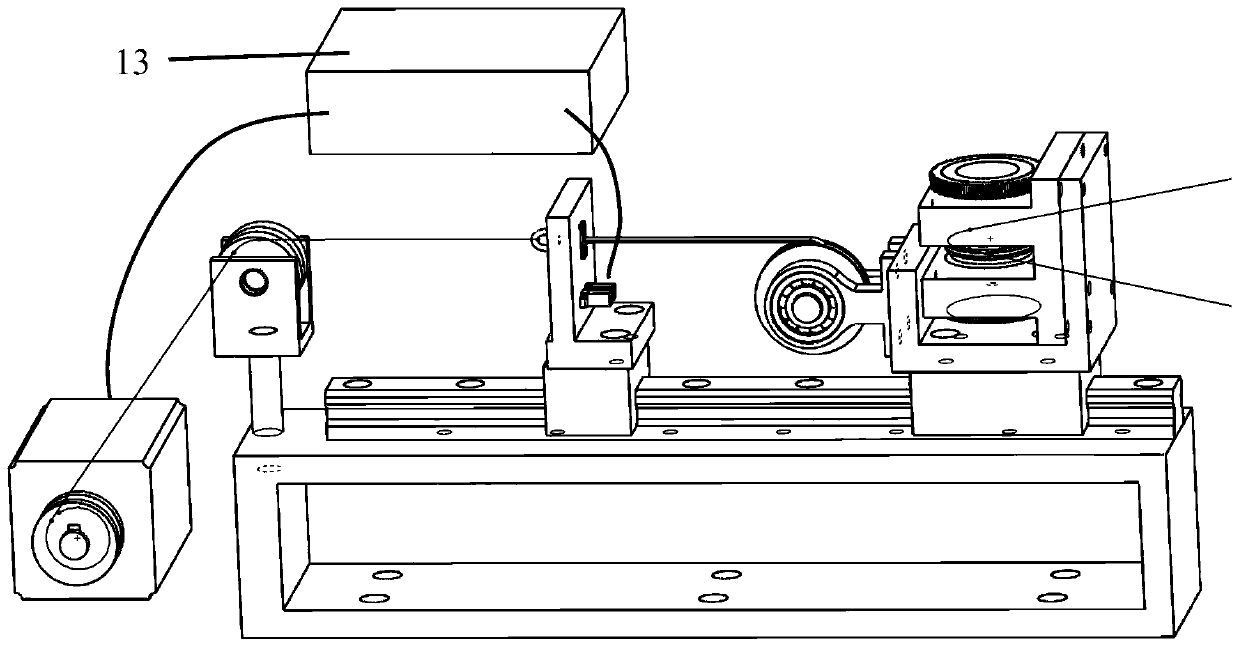

[0030] Such as figure 1 with figure 2 As shown, this embodiment discloses a wire electrode 12 tightness adjustment mechanism of a wire electric discharge machine tool, the adjustment mechanism mainly includes a mechanism fixing seat, a motor 1, a steel rope 3, a pulley 2, a pulley bracket, a first base 5, First slide block 6 , distance measuring sensor 7 , constant force spring 8 , spring support, second base 11 , second slide block 10 , tensioning guide wheel 9 , machine tool controller 13 and guide rail 4 .

[0031] Specifically, the mechanism fixing seat is fixedly connected with the machine tool. The guide rail 4 is installed on the mechanism fixing seat. Both the first slider 6 and the second slider 10 are installed on the guide rail 4 and can slide back and forth along the guide rail 4 . The tension guide wheel 9 is fixedly connected with the second slider 10 through the second base 11, and the tension guide wheel 9 can rotate freely, and the electrode wire 12 goes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com