Filling device for resin

A filling device and resin technology, which is applied in the direction of ion exchange column/bed method, ion exchange water/sewage treatment, etc., can solve the problem of difficult control of resin loading in batches, poor performance consistency of batch products, and filling resin piles Insufficient density and other problems, to achieve the effect of simplifying the resin filling process, ensuring consistent batches, and reducing the risk of resin delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

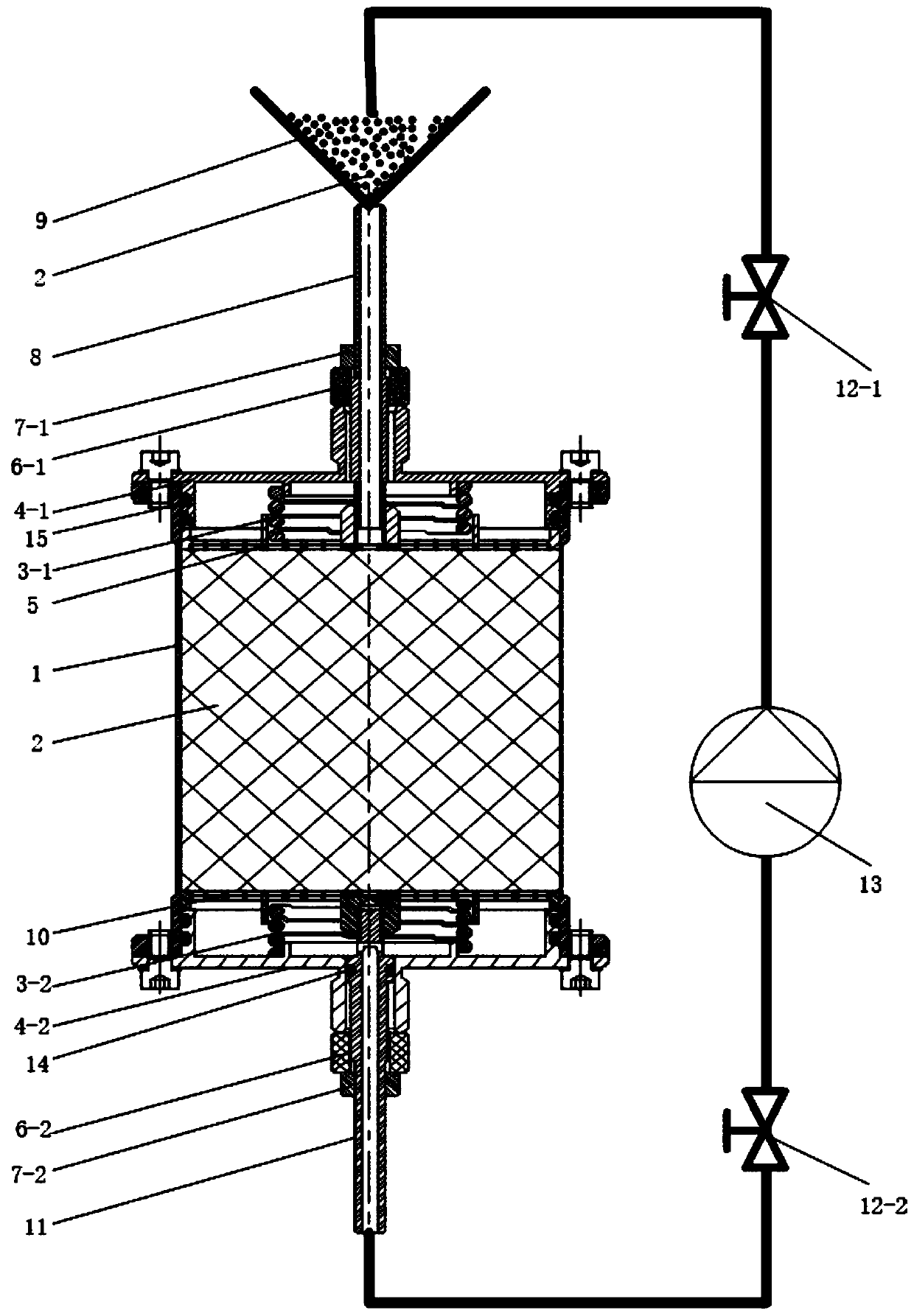

[0037] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

[0038] A specific embodiment of the present invention discloses a resin filling device, such as image 3 As shown, it is made up of a straight cylinder 1, an inlet assembly, an outlet assembly, a feed funnel 9 and a circulating water pump 13.

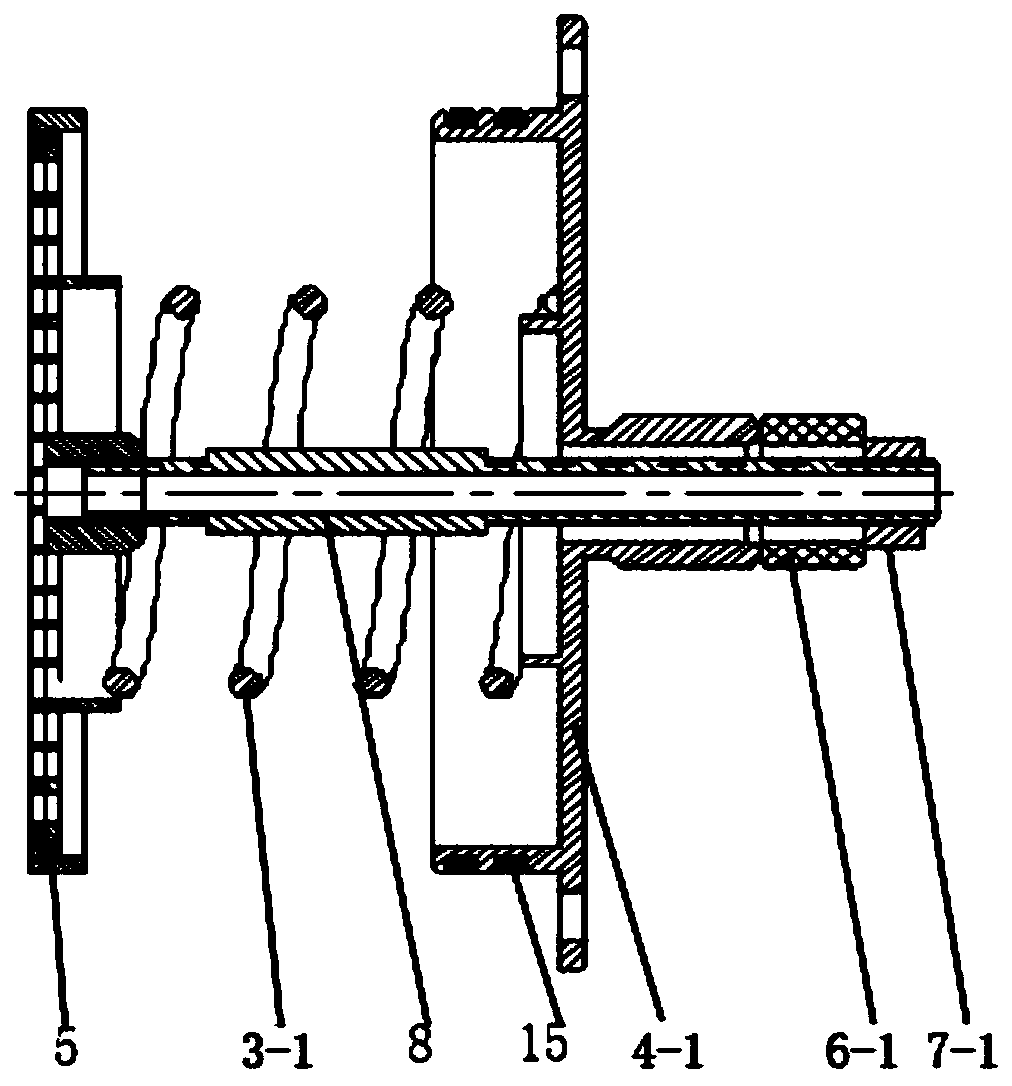

[0039] Wherein, the inlet assembly includes: inlet conduit 8, inlet diaphragm 5, first spring 3-1, first end cap 4-1, first protection block 6-1 and first nut 7-1.

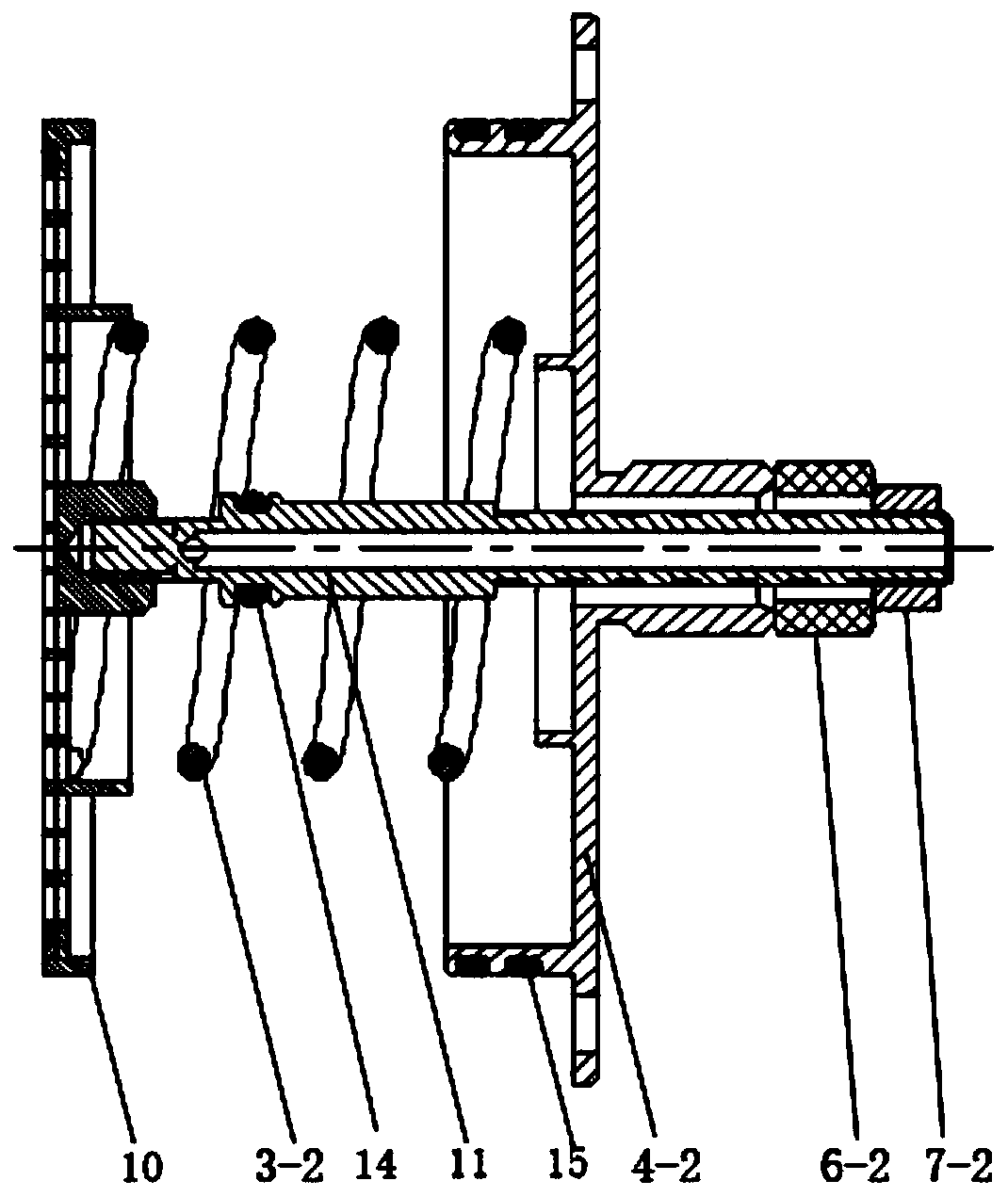

[0040] The outlet assembly includes: an outlet conduit 11, an outlet diaphragm 10, a second spring 3-2, a second end cap 4-1, a second protection valve 6-2 and a second nut 7-2.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com