Production and application of nano-hybrid material

A technology of nano-hybrid materials and composite materials, applied in inorganic chemistry, alkali metal compounds, other chemical processes, etc., to achieve the effect of improving bacteriostatic and anti-biological fouling properties, improving stacking phenomenon and lipophilicity, and preventing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation of the nano-hybrid material specifically comprises the following steps:

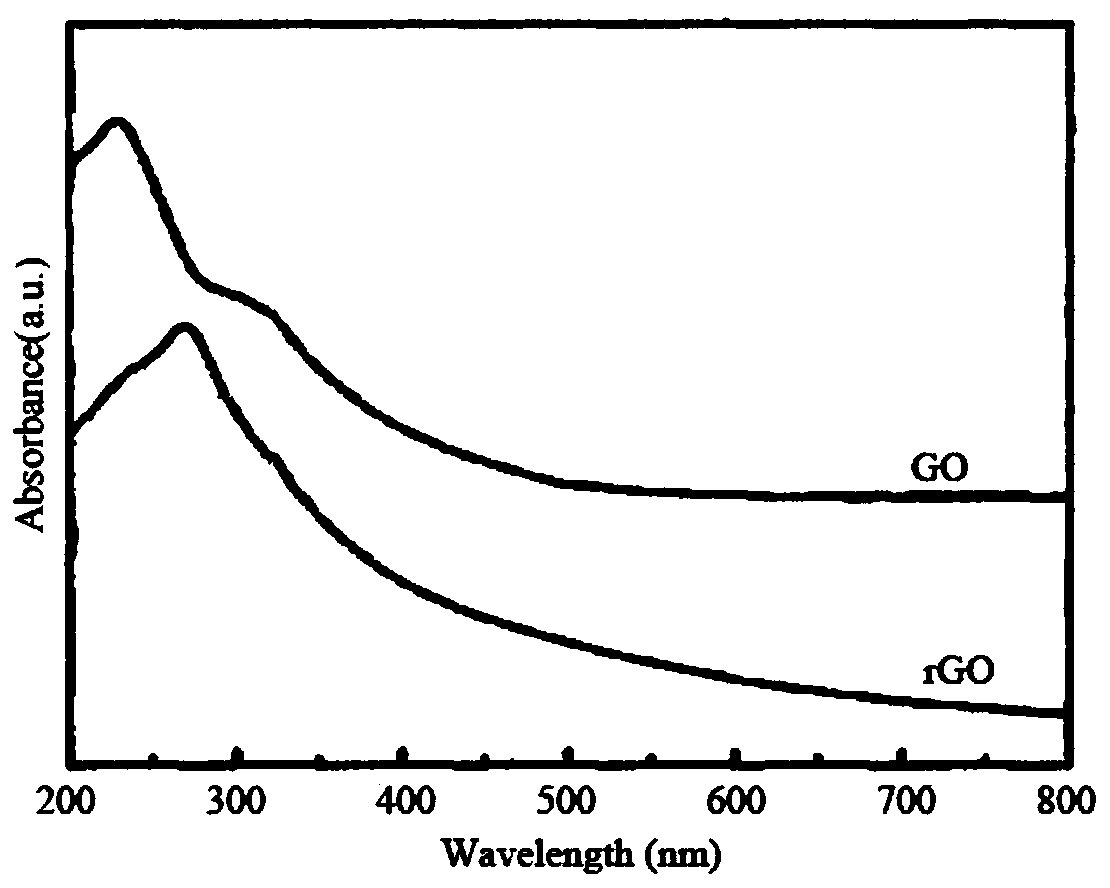

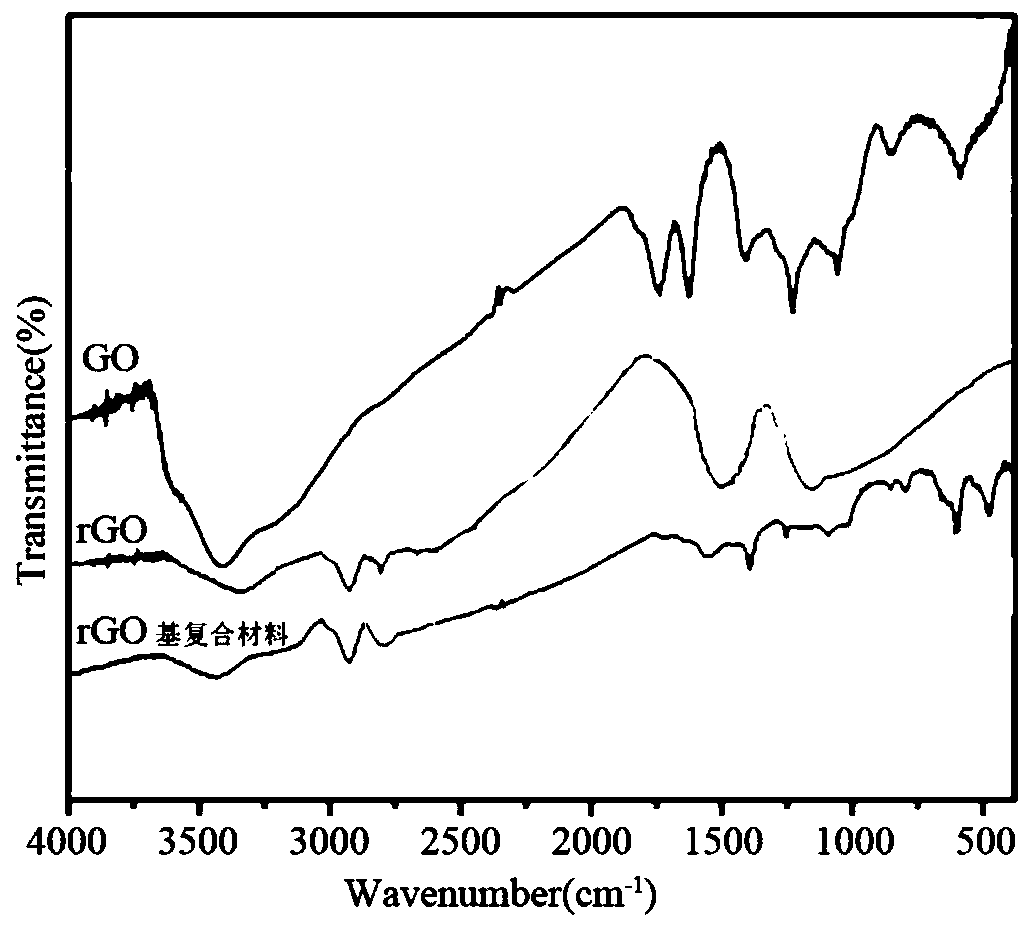

[0051] Step S1: Disperse GO in DMF at a solid-to-liquid ratio of 1:4-6mg / mL. After ultrasonic dispersion is uniform, add 3-O-methyl gallic acid, continue ultrasonication for 10-30min, and then heat to 100°C under nitrogen protection. Stir and react at -120°C for 20-30 hours, filter after the reaction, wash the product with absolute ethanol for 3-5 times, and freeze-dry to obtain rGO;

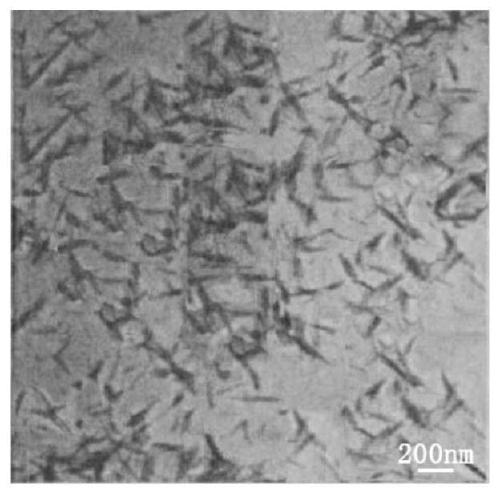

[0052] Step S2: Disperse iron salt, manganese salt and rGO in 20-50% DMF according to the solid-to-liquid ratio of 1:20-60mg / mL, stir at 70-90°C for 1-2h, and then use 5-10M hydrogen Sodium oxide solution adjusts the pH to 10.0-12.0, reacts for 5-10 minutes, cools to room temperature, and washes with absolute ethanol for 3-5 times to remove unreacted ions, and freeze-dries to obtain the rGO-based composite material;

[0053] Step S3: add the rGO-based composite material and fiber raw materials into ...

Embodiment 1

[0064] The preparation of the nano-hybrid material specifically comprises the following steps:

[0065] Step S1: Disperse GO in DMF at a solid-to-liquid ratio of 1:4 mg / mL, and add 3-O-methyl gallic acid after ultrasonic dispersion, wherein the weight ratio of GO and 3-O-methyl gallic acid is 1 :5, continue to sonicate for 10min, then heat to 100°C under nitrogen protection, stir for 20h, filter after the reaction, and wash the product 3 times with absolute ethanol, freeze-dry to obtain rGO;

[0066] Step S2: Disperse rGO, ferric chloride hexahydrate and manganese sulfate monohydrate with a weight ratio of 1:5.8:1.2 in 20% DMF at a solid-to-liquid ratio of 1:20 mg / mL, stir at 70°C for 1 h, and then Adjust the pH to 10.0 with 8M sodium hydroxide solution, react for 5 minutes, cool to room temperature, wash with absolute ethanol 3 times, remove unreacted ions, and freeze-dry to obtain the rGO-based composite material;

[0067]Step S3: Add rGO-based composite materials and PAN r...

Embodiment 2

[0069] The preparation of the nano-hybrid material specifically comprises the following steps:

[0070] Step S1: Disperse GO in DMF at a solid-to-liquid ratio of 1:6 mg / mL, and add 3-O-methyl gallic acid after ultrasonic dispersion, wherein the weight ratio of GO and 3-O-methyl gallic acid is 1 :20, continue ultrasonication for 10-30min, then heat to 120°C under nitrogen protection, stir and react for 30h, filter after the reaction is over, wash the product 5 times with absolute ethanol, and freeze-dry to obtain rGO;

[0071] Step S2: Disperse rGO, ferric chloride hexahydrate and manganese sulfate monohydrate with a weight ratio of 1:6.0:2.5 in 50% DMF at a solid-to-liquid ratio of 1:60 mg / mL, stir at 90°C for 2h, and then Use 8M sodium hydroxide solution to adjust the pH to 12.0, react for 10 minutes, cool to room temperature, wash with absolute ethanol for 5 times, remove unreacted ions, and freeze-dry to obtain the rGO-based composite material;

[0072] Step S3: Add rGO-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com