Compressor

A technology for a compressor and a compression mechanism, applied in the field of compressors, can solve the problems of low stability, large heat release, and reduced reliability of refrigeration cycle devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

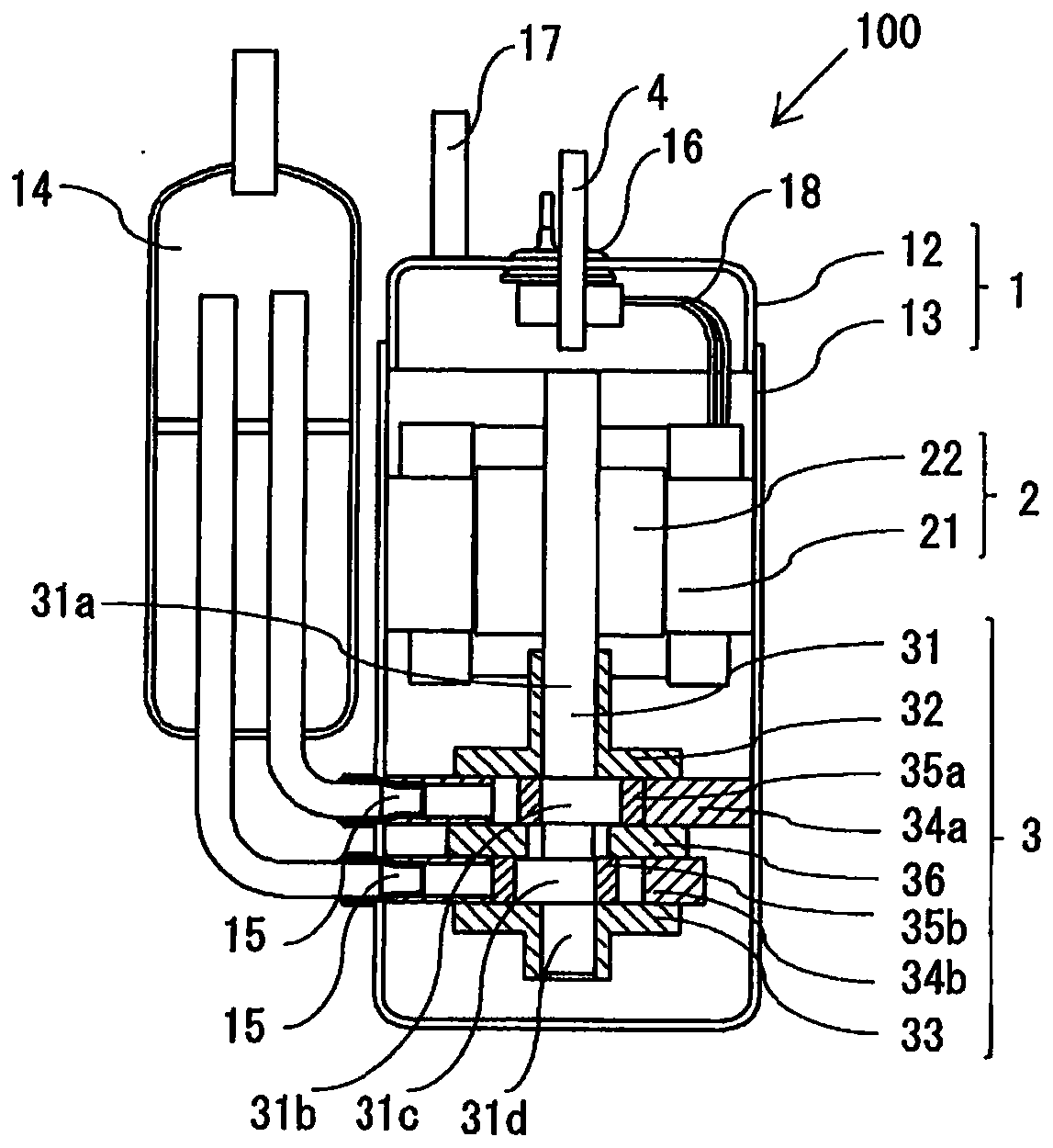

[0020] figure 1 It is an internal configuration diagram showing the inside of the compressor according to Embodiment 1 of the present invention. In the following description, as a compressor, a twin-rotor compressor 100 having two cylindrical cylinders in a compression mechanism will be described as an example. Such as figure 1 As shown, the compressor 100 is a hermetic electric compressor including a sealed container 1 , and a motor unit 2 and a compression mechanism unit 3 inside the sealed container 1 .

[0021] The airtight container 1 is composed of a bottomed cylindrical lower airtight container 13 and an upper airtight container 12 that closes the upper opening of the lower airtight container 13 . The connection part of the lower airtight container 13 of the airtight container 1 and the upper airtight container 12 is fixed by welding, which ensures the airtight state.

[0022] A suction pipe 15 is connected to the lower airtight container 13 , and a suction muffler 1...

Embodiment approach 2

[0086] The compressor according to Embodiment 1 of the present invention has been described in which a single refrigerant of R1123 refrigerant which is one type of hydrofluoroolefin is used as the operating refrigerant of the compressor 100 . In the compressor according to Embodiment 2 of the present invention, other operating refrigerants used in compressor 100 will be described.

[0087] The operating refrigerant is not limited to the single refrigerant of the R1123 refrigerant, and the R1123 refrigerant and the R32 refrigerant may be mixed and used in order to ensure the refrigeration capacity. Among them, the GWP of the mixed refrigerant is preferably less than 500, more preferably less than 100.

[0088] Table 2 shows a pressure comparison and physical property values of a refrigerant mixture between the R1123 refrigerant and the R32 refrigerant used as a conventional refrigerant. The operating conditions of the compressor were obtained by setting the condensing temper...

Embodiment approach 3

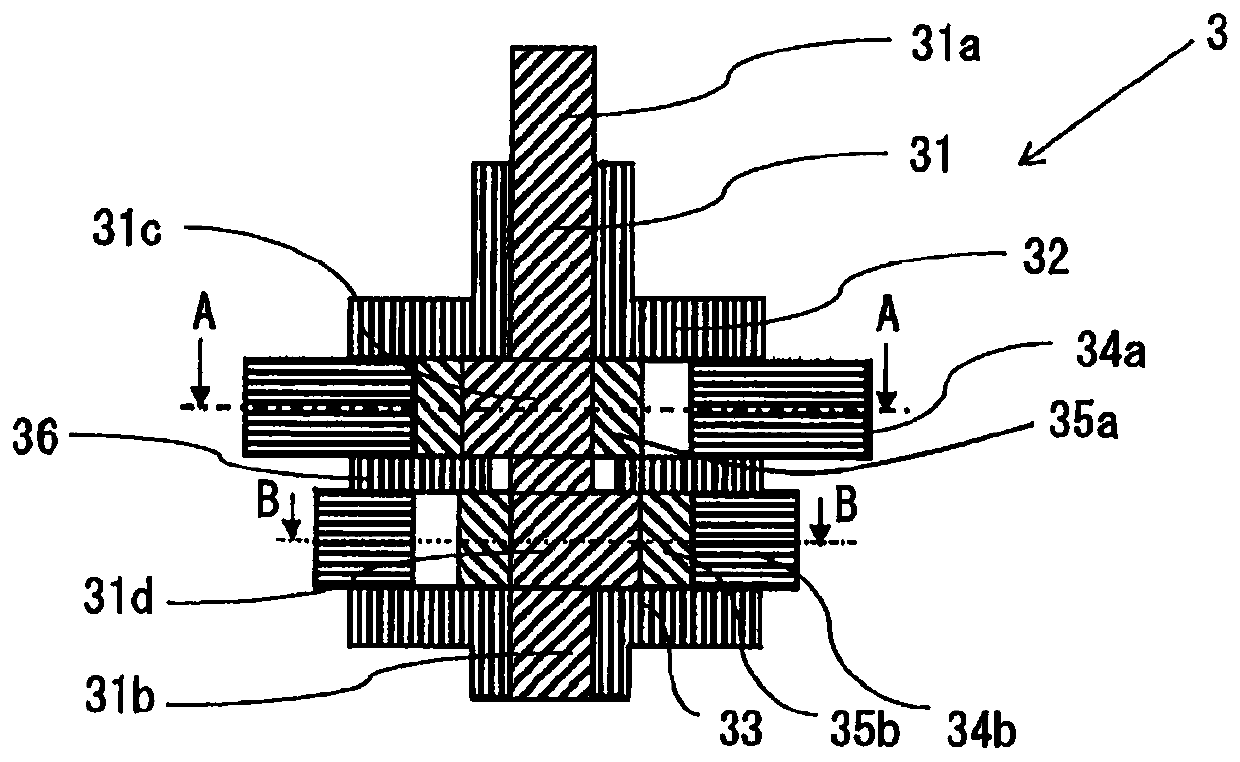

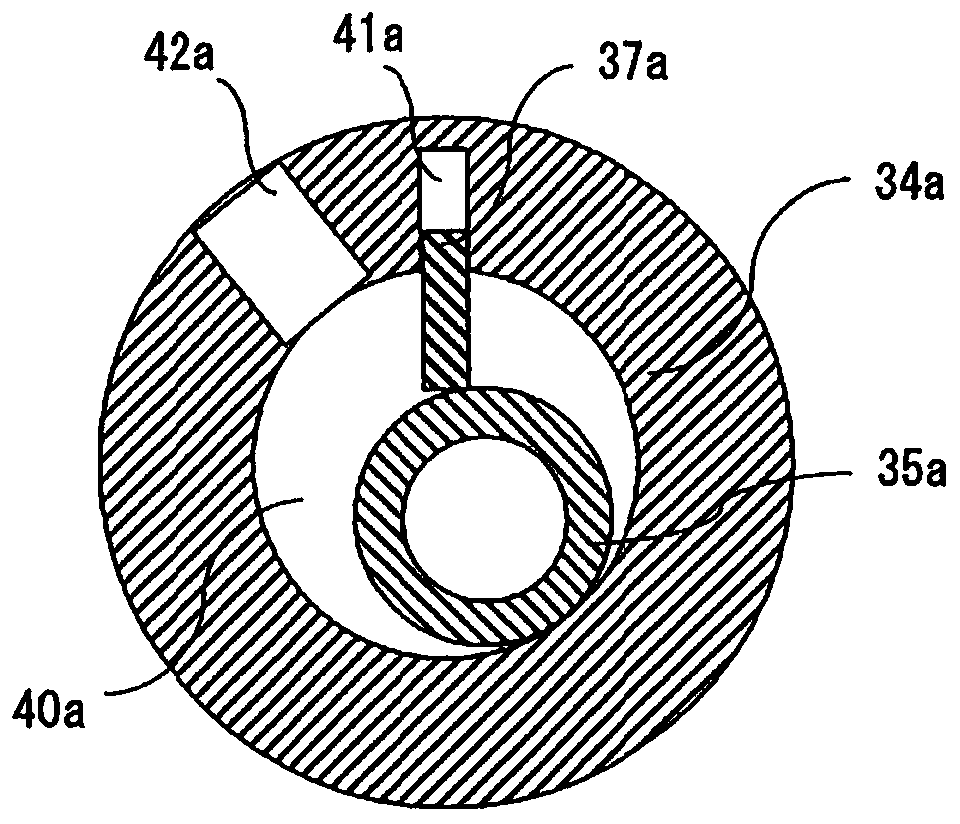

[0127] In the compressor according to Embodiment 3 of the present invention, solid lubrication treatment is performed on the rotary shaft 31 of the compressor 100 . In addition, the main bearing 32 or the sub-bearing 33 may be subjected to solid lubrication treatment together with the rotating shaft 31 or may be subjected to the solid lubrication treatment on the main bearing 32 or the sub-bearing 33 instead of the rotating shaft 31 . By performing solid lubrication treatment on the rotating shaft 31 , the main bearing 32 and the sub-bearing 33 , the heat-generating sticking between the rotating shaft 31 and the main bearing 32 or between the rotating shaft 31 and the sub-bearing 33 during operation of the R1123 refrigerant can be further suppressed.

[0128] In addition, when the tip portion of the sub shaft portion 31b of the rotating shaft 31 is in contact with the inner wall of the sub bearing 33 as a support point, the sub shaft portion 31b may be selectively subjected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com