A wearable breathable self-cleaning high electromagnetic shielding film and preparation method thereof

An electromagnetic shielding and self-cleaning technology, applied in the fields of magnetic/electric field shielding, shielding materials, electrical components, etc., can solve problems such as insufficient shielding effectiveness, wearable electromagnetic shielding materials unable to self-clean, human toxicity, etc., to improve efficiency and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

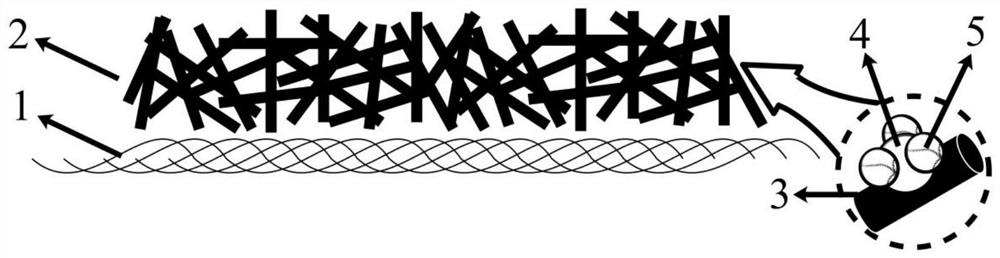

[0036] This embodiment provides a preparation method of a wearable breathable self-cleaning high electromagnetic shielding film, comprising the following steps:

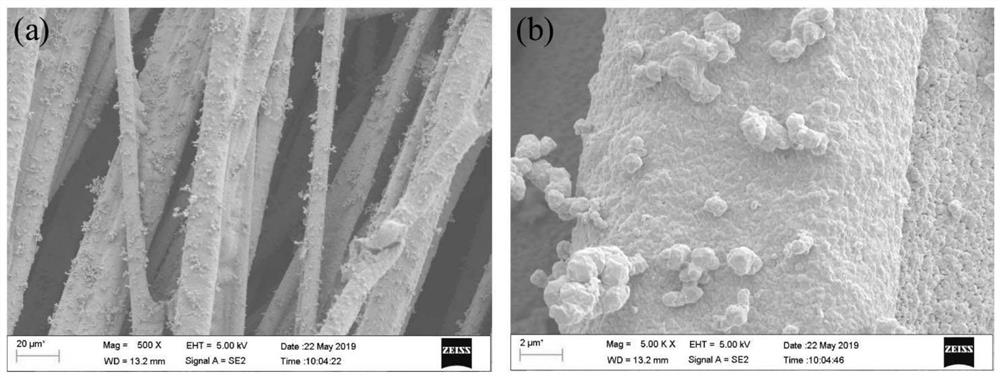

[0037] (1) Cut 0.503 g carbon fiber tow and 0.754 g ES fiber tow into 6 mm length with a fiber chopping machine to obtain chopped carbon fiber and chopped ES fiber, put the chopped carbon fiber and chopped ES fiber into 170 ml hydroxyl Mix in the ethyl cellulose solution, the solvent of the hydroxyethyl cellulose solution is deionized water, the concentration is 0.012 g / ml, stir at 600 rpm for 5 min, let stand for 5 min, and then make carbon fiber by paper forming machine Non-woven fabrics were dried in a constant temperature drying oven at 60 °C for 45 min. Put the dried porous carbon fiber non-woven fabric into a programmed tablet press and press it to make the carbon fibers firmly bond. The hot-pressing time is 10 min, the hot-pressing temperature is 150 ℃, the hot-pressing pressure is 6 MPa, and the porous carbo...

Embodiment 2

[0045] This embodiment provides a preparation method of a wearable breathable self-cleaning high electromagnetic shielding film, comprising the following steps:

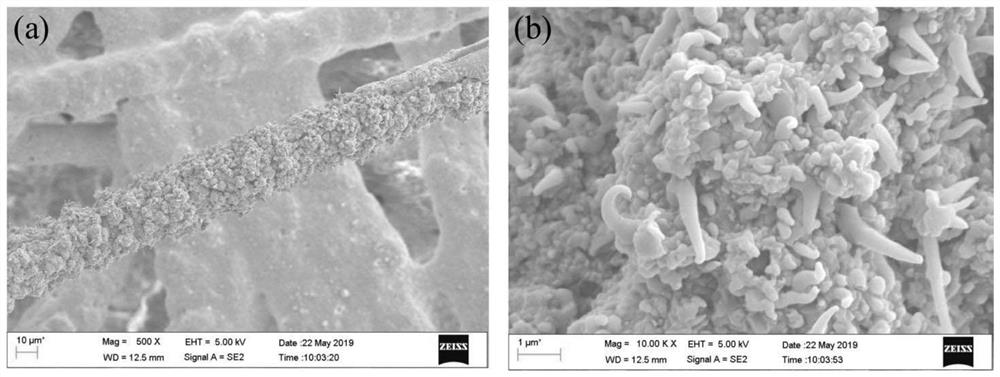

[0046] (1) Cut 0.503 g carbon fiber tow and 0.754 g ES fiber tow into 6 mm length with a fiber chopping machine to obtain chopped carbon fiber and chopped ES fiber, put the chopped carbon fiber and chopped ES fiber into 170 ml hydroxyl Mix in the ethyl cellulose solution, the solvent of the hydroxyethyl cellulose solution is deionized water, the concentration is 0.012 g / ml, stir at 600 rpm for 5 min, let stand for 5 min, and then make carbon fiber by paper forming machine Non-woven fabrics were dried in a constant temperature drying oven at 60 °C for 45 min. Put the dried porous carbon fiber non-woven fabric into a programmed tablet press and press it to make the carbon fibers firmly bond. The hot-pressing time is 10 min, the hot-pressing temperature is 150 ℃, the hot-pressing pressure is 6 MPa, and the porous carbo...

Embodiment 3

[0054] This embodiment provides a preparation method of a wearable breathable self-cleaning high electromagnetic shielding film, comprising the following steps:

[0055] (1) Cut 0.503 g carbon fiber tow and 0.754 g ES fiber tow into 6 mm length with a fiber chopping machine to obtain chopped carbon fiber and chopped ES fiber, put the chopped carbon fiber and chopped ES fiber into 170 ml hydroxyl Mix in the ethyl cellulose solution, the solvent of the hydroxyethyl cellulose solution is deionized water, the concentration is 0.012 g / ml, stir at 600 rpm for 5 min, let stand for 5 min, and then make carbon fiber by paper forming machine Non-woven fabrics were dried in a constant temperature drying oven at 60 °C for 45 min. Put the dried porous carbon fiber non-woven fabric into a programmed tablet press and press it to make the carbon fibers firmly bond. The hot-pressing time is 10 min, the hot-pressing temperature is 150 ℃, the hot-pressing pressure is 6 MPa, and the porous carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com