Tray degassing room

A technology of air chambers and pallets, which is applied in electrical components, industrial buildings, and insulation of conductors/cables. It can solve the problems of shipment, turnover, inability to feed insulated core wires, and affect the normal production of cables. It achieves good versatility, Stable and firm assembly, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

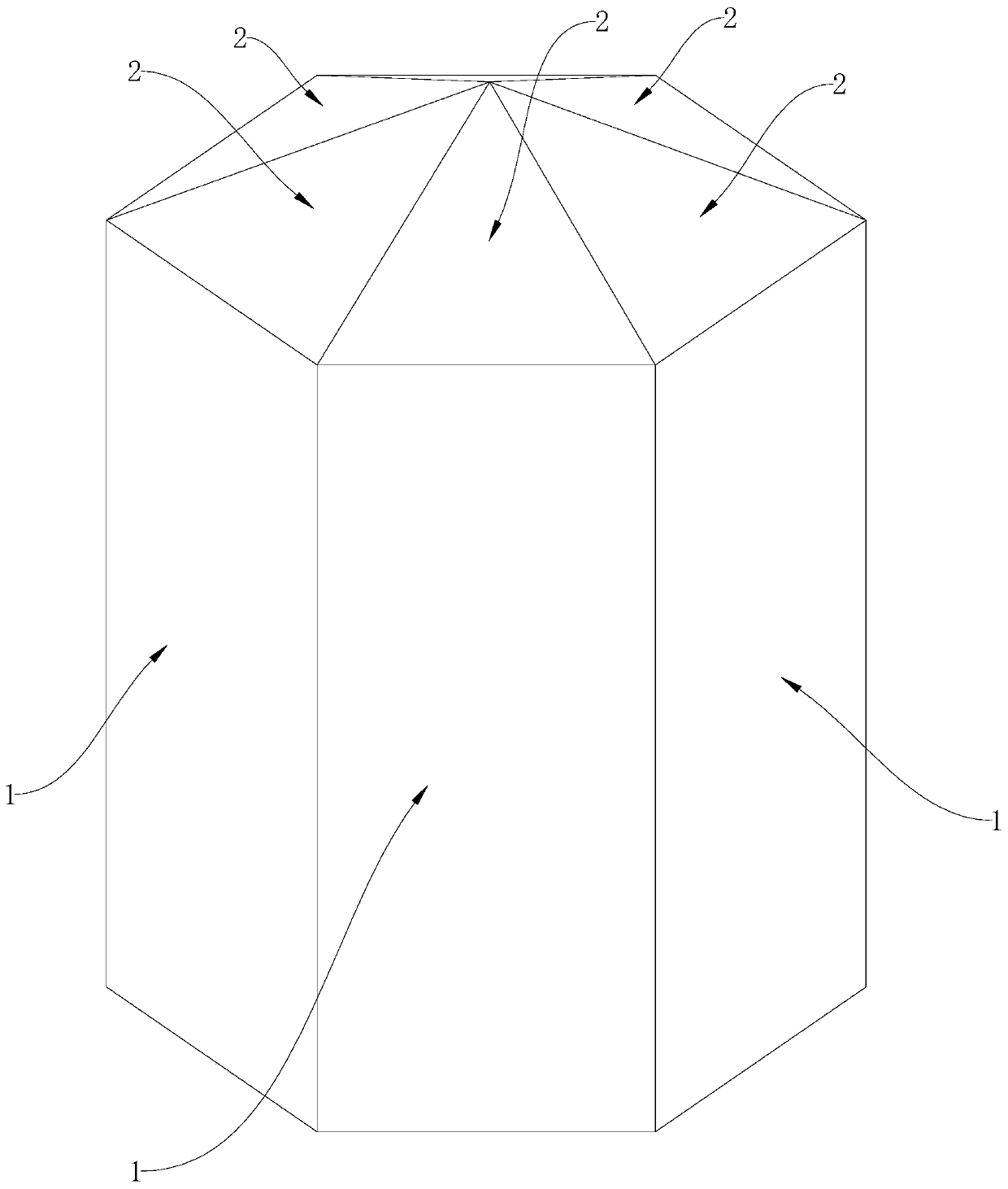

[0029] Embodiment one: if Figure 1 to Figure 5 As shown, a pallet degassing room includes a plurality of modular assembly units, each assembly unit includes a wall assembly unit for forming a wall and a roof assembly unit for forming a top cover, and multiple wall assemblies The assembling units surround and assemble to form the wall of the degassing room, and a plurality of top cover assembling units surround and assemble to form the top cover of the degassing room.

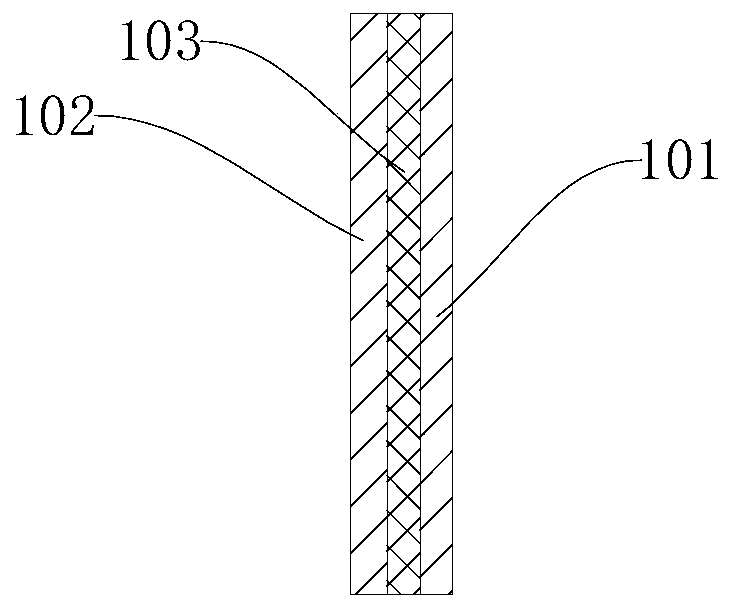

[0030] In this specific embodiment, the wall assembly unit includes at least one vertically arranged rectangular assembly board 1, the roof assembly unit includes at least one triangular assembly board 2, and each rectangular assembly board 1 is reversibly provided with a triangular assembly board. plate 2.

[0031] In this specific embodiment, the reversible connection between the rectangular assembled board 1 and the triangular assembled board 2 is realized through the hinge 3 .

[0032] In this specific em...

Embodiment 2

[0038] Embodiment two: if Image 6 , Figure 7 As shown, other parts are the same as in Embodiment 1, the difference is that each wall assembly unit includes at least two rectangular assembly panels 1, and the adjacent rectangular assembly panels 1 in each wall assembly unit can be flip connection;

[0039] The outside portion of the rectangular assembly plate 1 located on one outside of each wall assembly unit is provided with a first insertion projection 11, and the outside portion of the rectangular assembly plate 1 located on the other outside of each wall assembly unit is provided with There is a first insertion groove 12 corresponding to and matched with the position of the first insertion protrusion 11, and two adjacent wall assembly units are plugged in through the first insertion protrusion 11 provided on one of the wall assembly units. Connect and install the first socket groove 12 on another wall assembly unit to realize assembly connection;

[0040] One side pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com