Airtight member of neodymium iron boron storage container and sealing method

A storage container, NdFeB technology, applied in the sealing of the engine, engine components, grain processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

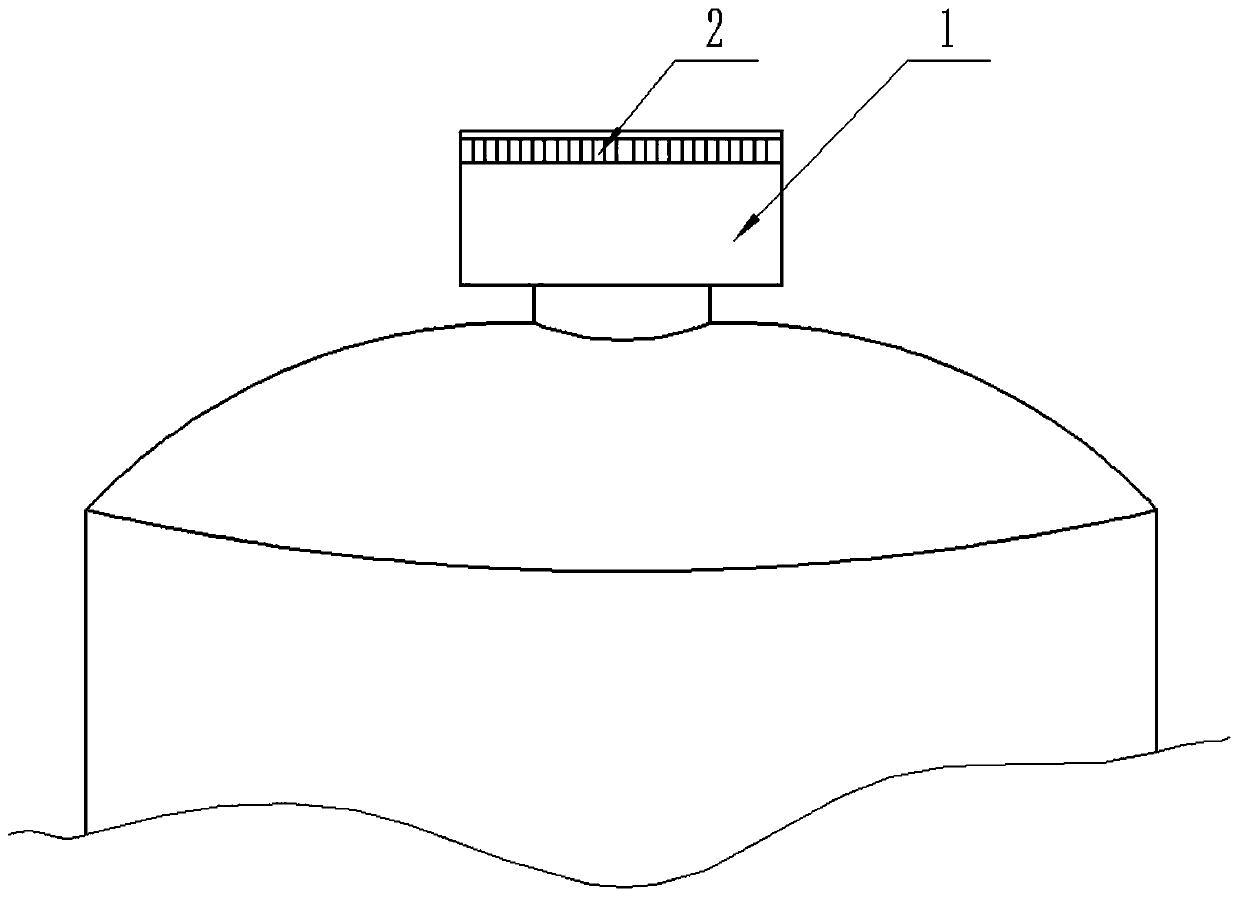

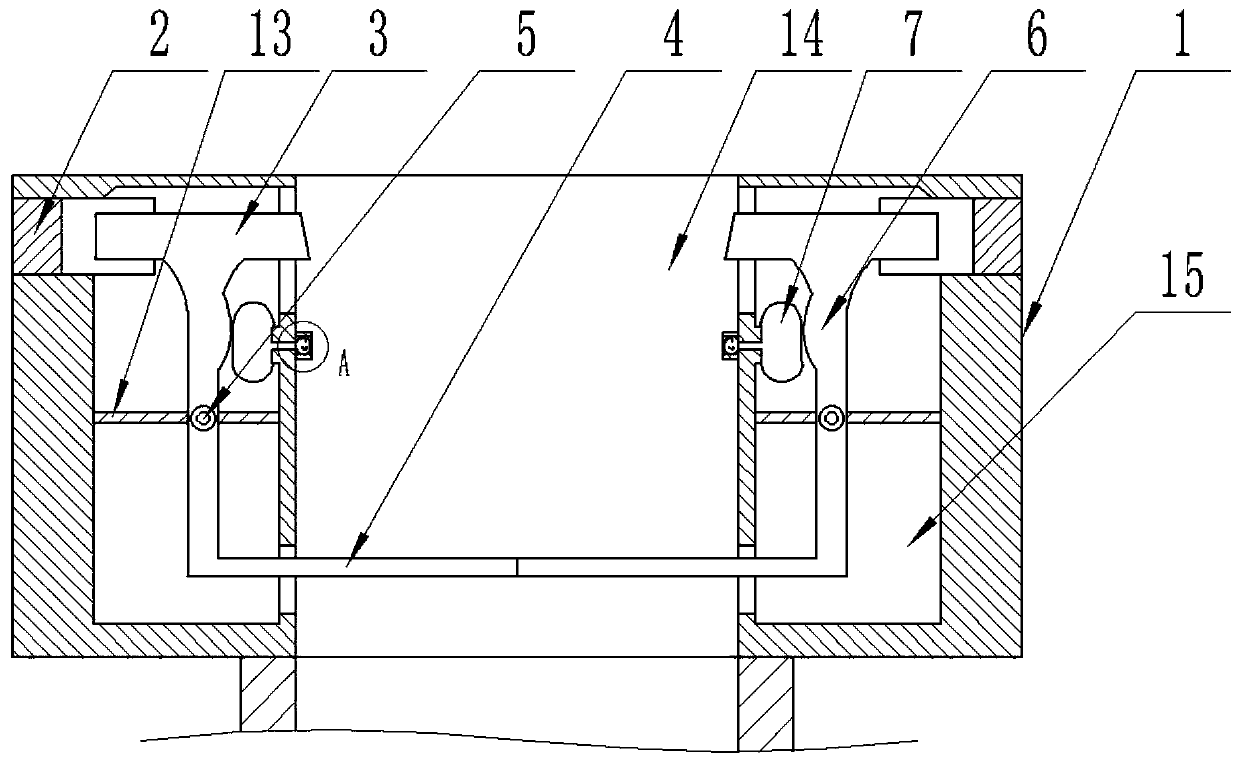

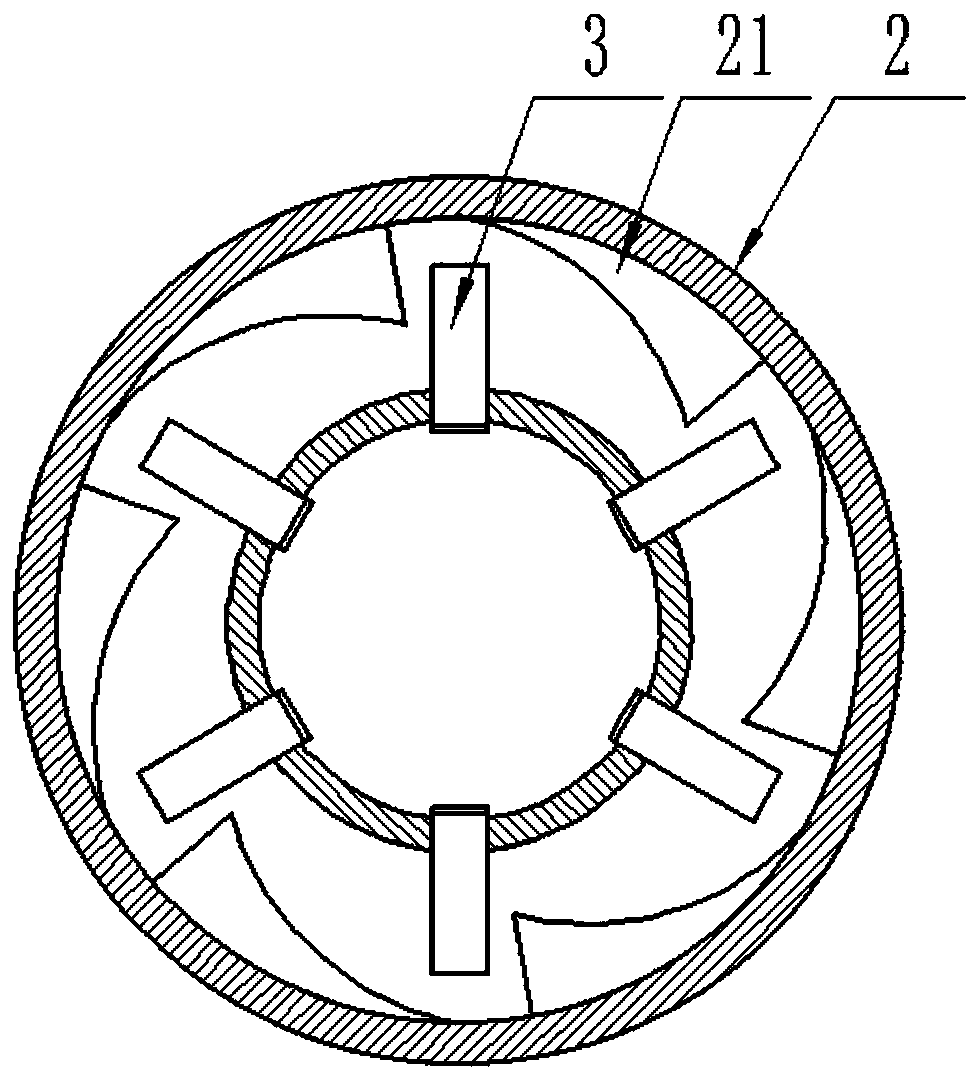

[0048] An airtight component of a neodymium-iron-boron material storage container, such as figure 1 , 2 As shown, including the component body, the component body is divided into an inner area and an outer area, the inner area has an accommodation space, and the outer area is a hollow structure, and the component body includes: a fastening ring, a pressure piece, a locking block, a rotating shaft, and a pressure block , Air pressure seals.

[0049] like Figure 2-4 As shown, the fastening ring is disposed on the outside of the component body. The pressing part is arranged inside the fastening ring, and the pressing part communicates with the inner area of the component body. The lock block is arranged in the inner area of the component body, the lock block corresponds to the inner side of the fastening ring, the side of the pressure member facing the lock block is an arc surface, one end of the arc surface is close to the inner side of the fastening ring, and the other ...

Embodiment 2

[0070] A neodymium-iron-boron material storage container, including the content of the technical solution in the first embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com