Method for manufacturing annular lifting belt with weft constraint

A manufacturing method and a technology of a sling, which are applied to rope-making auxiliary devices, transportation and packaging, and load-hanging components, etc., can solve problems such as increased cost, low utilization rate of tow, and reduced utilization rate of materials, so as to improve quality and durability, improving the utilization rate of tow and improving the stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

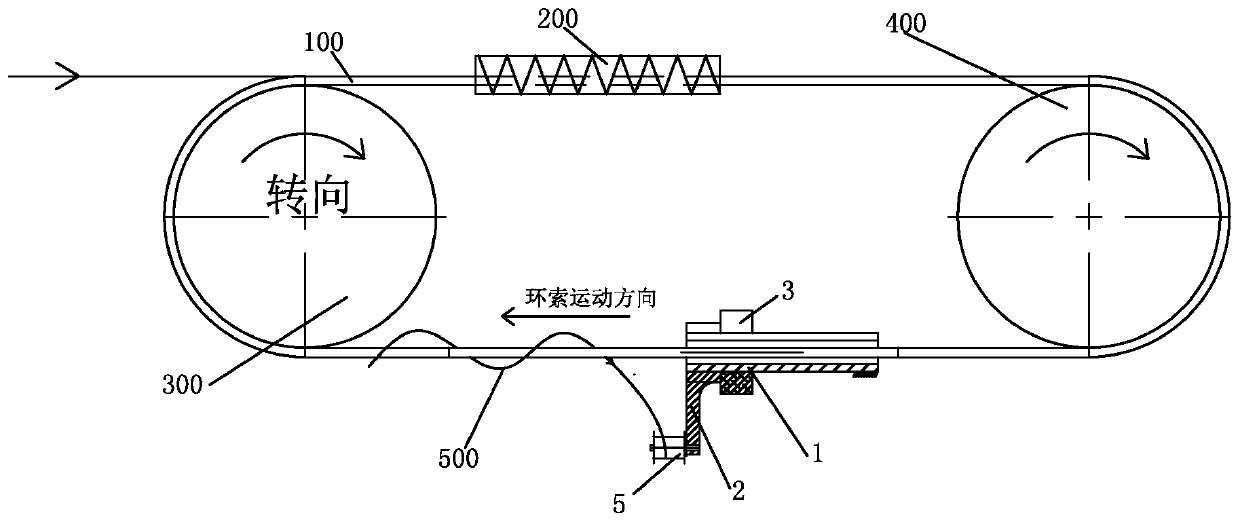

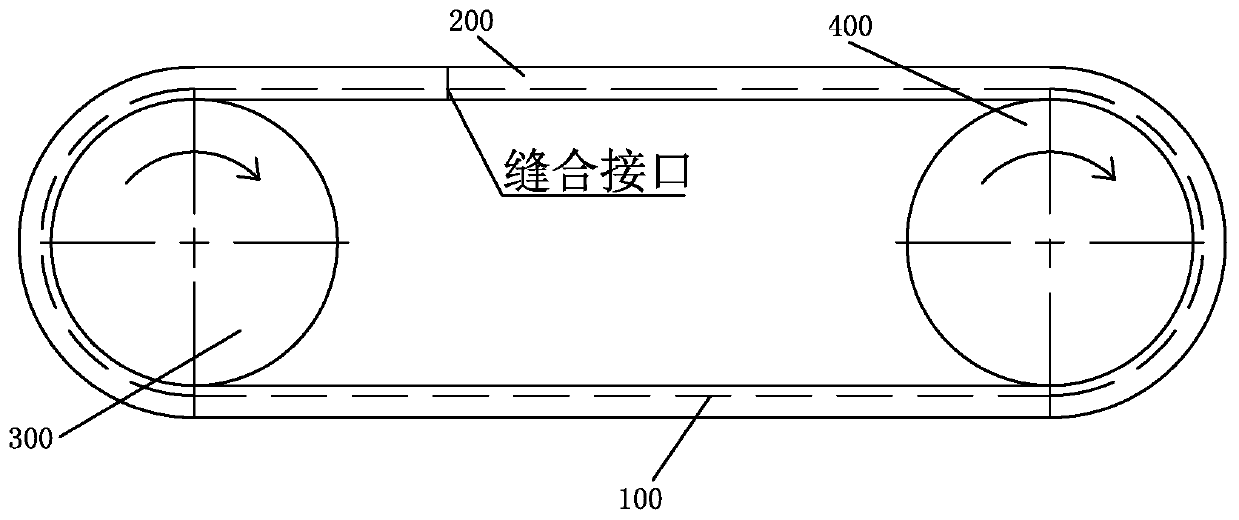

[0023] Such as figure 1 Shown, the manufacture method of the endless sling of the present invention band latitudinal binding comprises the steps:

[0024] Step 1: Pass the fiber tow 100 through the sheath 200 in the laminated state, and put it on the driving wheel 300 and the driven wheel 400 of the winding device to tighten it.

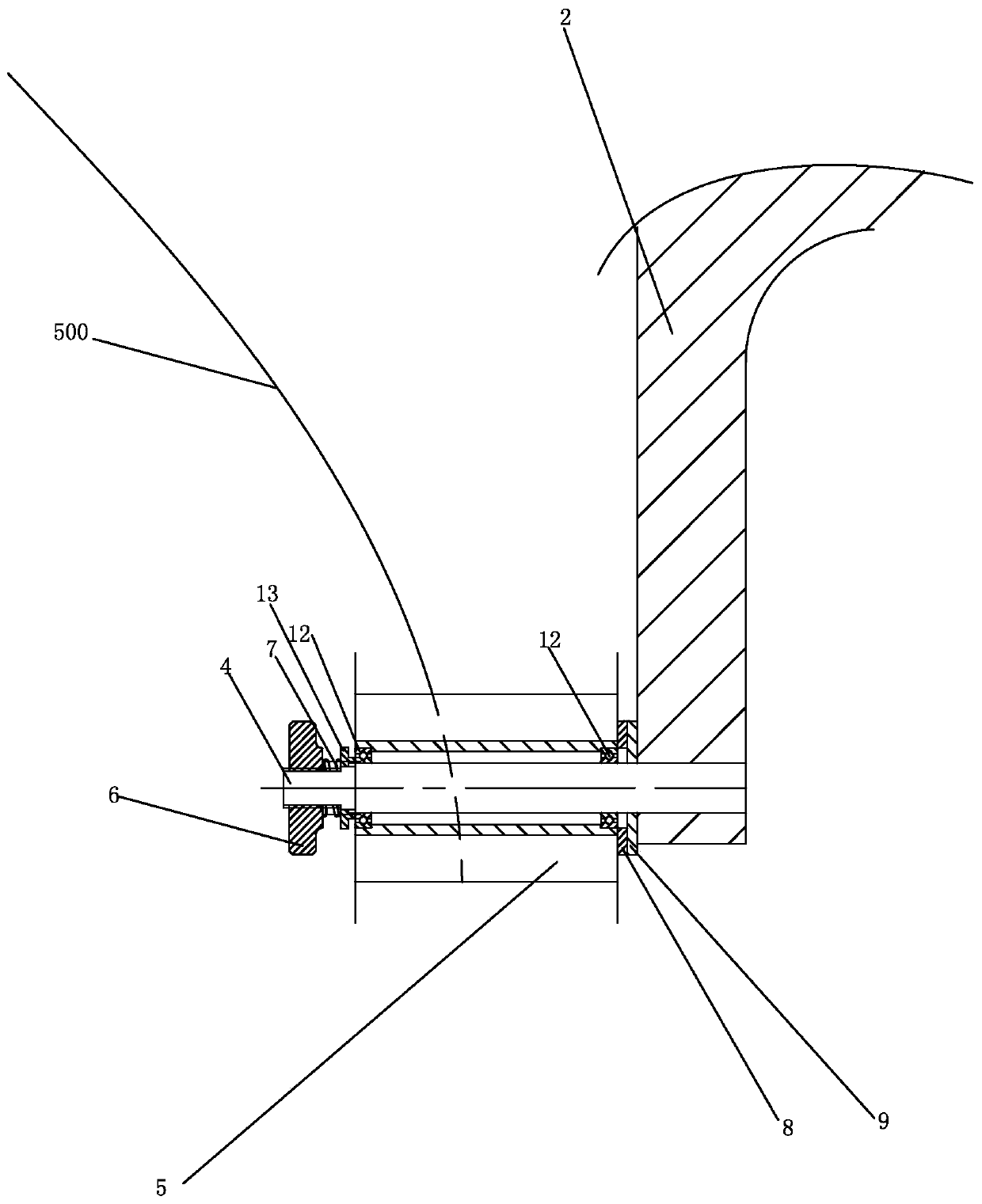

[0025] Step 2: install the rotating device 600 , take one end of the filament bundle 500 and wind it around the fiber bundle 100 . Installing the rotating device 600 includes: placing the rotating device 600 on one side of the driving wheel 300 and the driven wheel 400, so that the fiber tow 100 passes through the opening 11 of the fixed shaft 1 at the center of the fixed shaft 1, and winds the filament bundle outside the shaft 5 500, adjust the threaded connection depth between the pressure regulating nut 6 and the cantilever shaft 4, so as to adjust the tension of the filament bundle.

[0026] Step 3: start the winding equipment, the motor drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com