Halophilic alkalophilic biological desulfurizing treatment process and treatment device

A technology of biological desulfurization and treatment device, which is applied in the field of environmental engineering and can solve problems such as inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

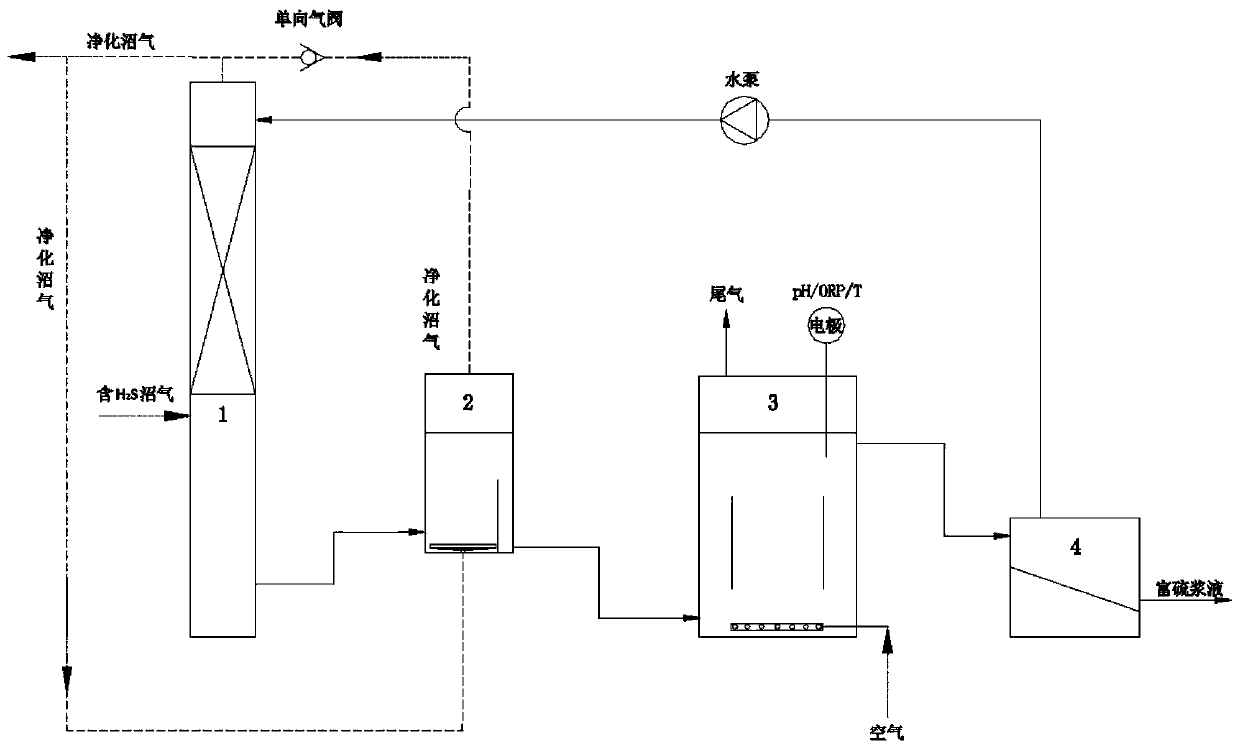

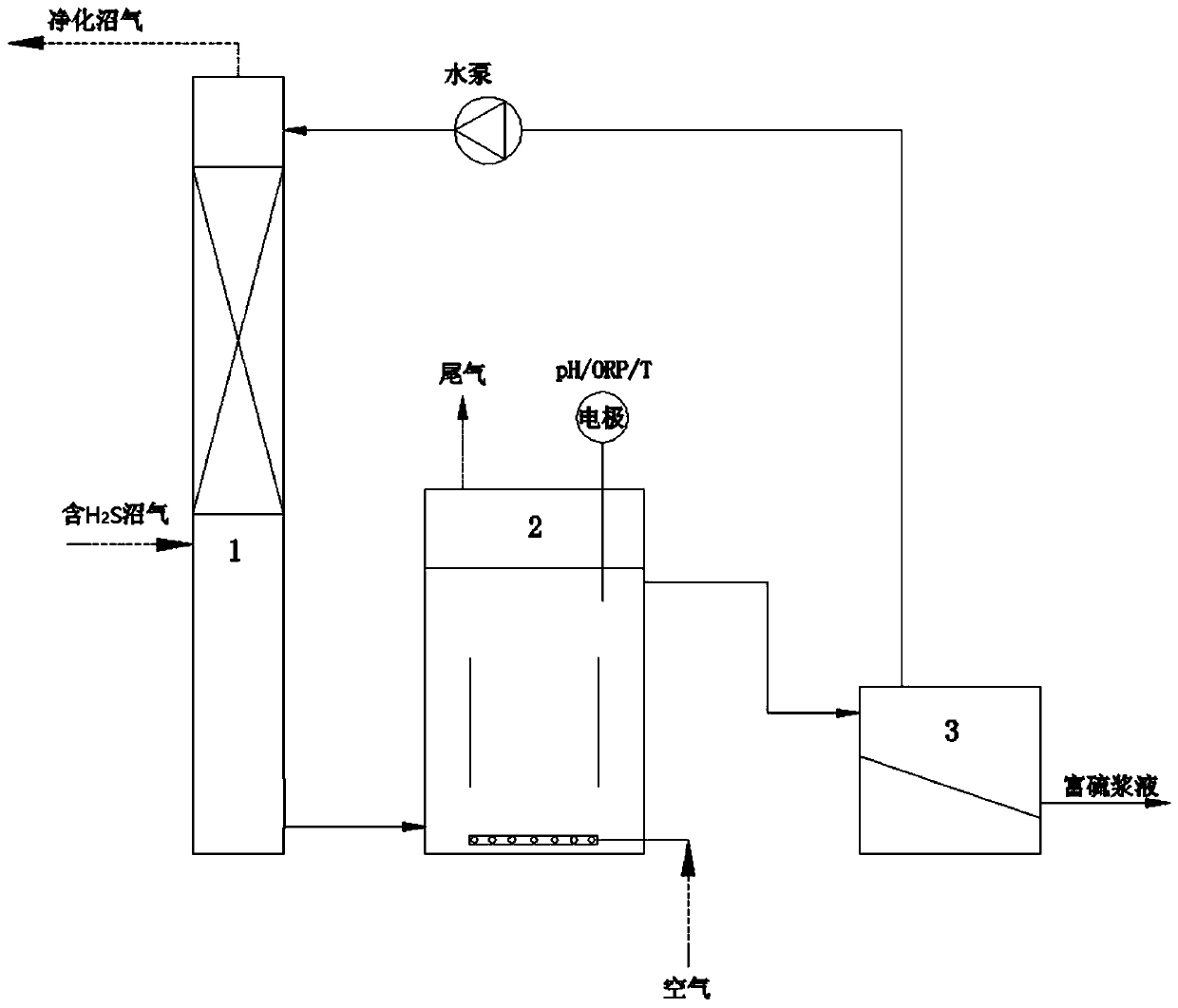

[0078] This embodiment provides a halophilic alkaliphilic biological desulfurization treatment device, such as figure 1 As shown, the device includes a sequentially connected biological purification tower 1, a deep adsorption tower 2, a biological regeneration tower 3 and a sulfur collection tower 4. The sulfur collection tower 4 is connected to the biological purification tower 1, and the above four tower units form a closed liquid circulation system;

[0079] Wherein, the deep adsorption tower 2 and the biological regeneration tower 3 are respectively provided with an aeration device;

[0080] A water pump is provided on the pipeline between the sulfur collection tower 4 and the biological purification tower 1;

[0081] The biological purification tower 1 is provided with an air intake pipeline and an air outlet pipeline, and a branch purification gas pipeline is provided on the air outlet pipeline, which is connected with the deep adsorption tower 2;

[0082] The deep ads...

Embodiment 2

[0085] This embodiment provides a halophilic and alkaliphilic biological desulfurization process, which is carried out using the device in Example 1, including the following steps:

[0086] (1) containing H 2 The S biogas is passed into the biological purification tower 1, and is countercurrently contacted with the absorption liquid to make the H 2 S to HS - Enter the liquid phase, the purified biogas is discharged from the purification tower, and one branch is separated from the purified biogas as the gas supply for the deep adsorption tower;

[0087] (2) The rich HS obtained in step (1) - The liquid enters the deep adsorption tower 2 through gravity flow, and the purified biogas derived from the biological purification tower 1 is used for the HS through the aeration device installed in the tower. - The rich liquid is aerated and stirred to form an anaerobic environment in the deep adsorption tower 2, strengthen the mass transfer of the system, and promote the reaction of ...

Embodiment 3

[0103] In this example, the device provided in Example 1 is used for halophilic and alkaliphilic biological desulfurization.

[0104] H in the biogas treated in this example 2 The S concentration is about 11000ppm, in addition to CH 4 58% with CO 2 32%, other gases accounted for about 10%.

[0105] Start the system according to the scheme of embodiment 2, the amount of biogas intake is 0.65m 3 / h, adjust the liquid flow, so that the H in the biogas purified at the gas outlet of the biological purification tower 2 The S content drops below 10ppm, at this time the liquid flow rate is 0.13m 3 / h.

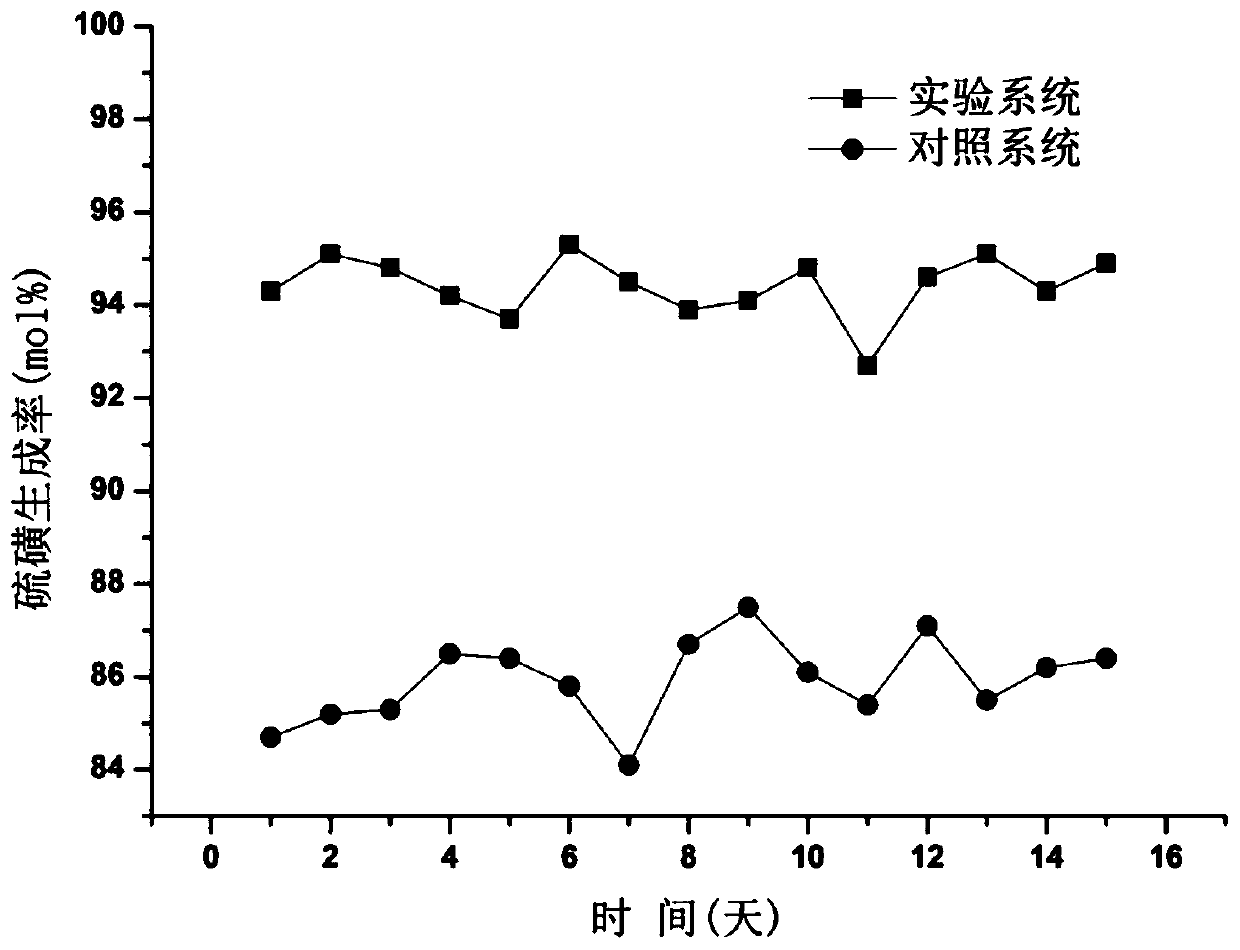

[0106] In this embodiment, desulfurization biogas purification effect, sulfur generation rate, S 2 o 3 2- and SO 4 2- Generation rate as Figure 7 and Figure 8 Shown: The hydrogen sulfide removal rate of the system reaches over 99.9%, and the gas H 2 The S content is reduced to below 10ppm, and the biogas is fully purified. The maximum elemental sulfur generation rate r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com