Additives for Alkaline Polishing of Silicon Wafers and Their Applications

A silicon wafer alkali and additive technology, applied in water-based dispersants, sustainable manufacturing/processing, final product manufacturing, etc., to achieve pollution-free and controllable polishing, increase slurry tension, and gain battery conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Preparation of additives: 0.75 parts by mass of gelatin, 2 parts by mass of acrylamide, 0.5 parts by mass of benzyltriethylammonium chloride, 3 parts by mass of sodium p-aminosalicylate, 4 parts by mass of ammonium thiocyanate, 3 parts by mass of Alkyl glycosides and 0.2 parts by mass of sodium benzoate were added to 86.55 parts by mass of deionized water, and mixed uniformly to prepare additives;

[0043] 2) Preparation of polishing liquid: add the additive prepared in step 1) into the potassium hydroxide solution, and mix evenly to prepare a polishing liquid; the mass ratio of the additive to the potassium hydroxide solution is 1:100; The mass percentage of potassium is 3%;

[0044] 3) Alkali polishing: use the polishing liquid prepared in step 2) to polish the single crystal silicon wafer, and the temperature of the polishing treatment is controlled at 70° C. and the time is controlled at 180s.

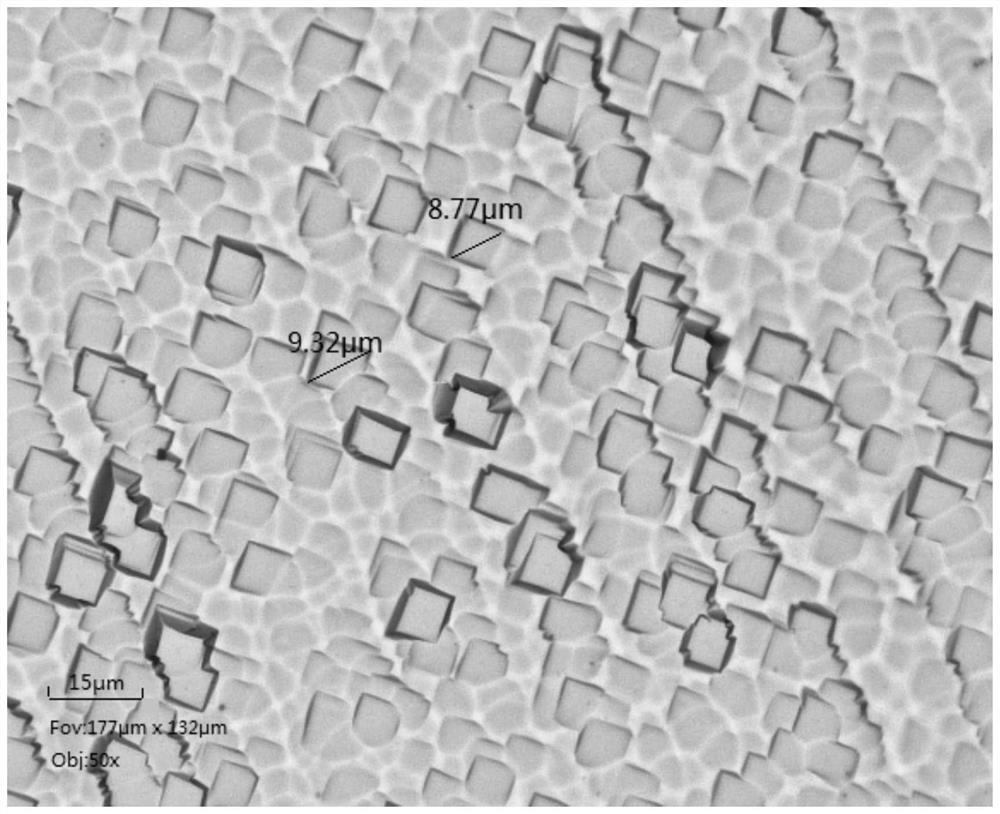

[0045] Example 1 The scanning electron microscope image of the back...

Embodiment 2

[0047] 1) Preparation of additives: 1.5 parts by mass of gelatin, 1.5 parts by mass of acrylamide, 1 part by mass of tetrabutylammonium chloride, 3 parts by mass of sodium p-aminosalicylate, 5 parts by mass of ammonium thiocyanate, 4 parts by mass of alkyl Glycosides and 0.2 parts by mass of sodium benzoate were added to 83.8 parts by mass of deionized water, and mixed evenly to prepare additives;

[0048] 2) Preparation of polishing liquid: Add the additive prepared in step 1) to the potassium hydroxide solution, and mix it evenly to prepare a polishing liquid; the mass ratio of the additive to the potassium hydroxide solution is 0.75:100; The mass percentage of potassium is 2.5%;

[0049] 3) Alkali polishing: use the polishing liquid prepared in step 2) to polish the single crystal silicon wafer, and the temperature of the polishing treatment is controlled at 60°C and the time is controlled at 240s).

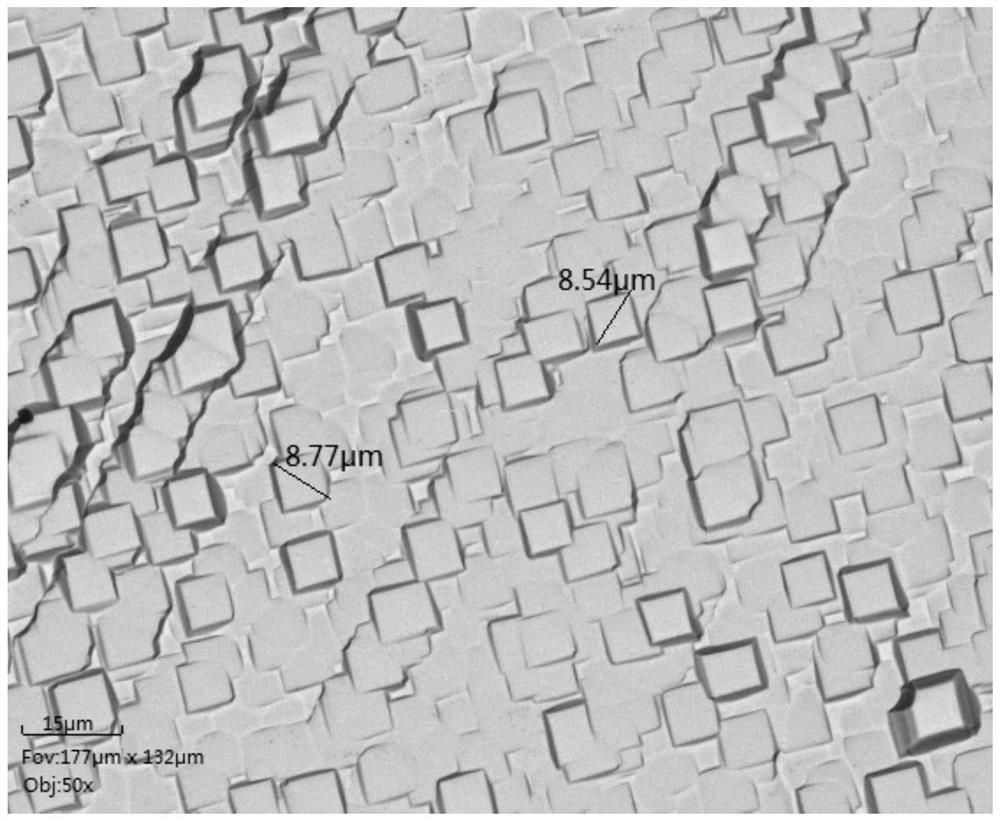

[0050] Example 2 The scanning electron microscope image of the back of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com