Device and method for studying performance of steel pipe concrete compression-bending member under loads and corrosion

A technology for steel pipe concrete and components, which is applied in the directions of measuring devices, weather resistance/light resistance/corrosion resistance, and the use of stable bending force to test the strength of materials, etc., which can solve the problem that the long-term load action and electrochemical Corrosion and other issues to achieve the effect of speeding up the test progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

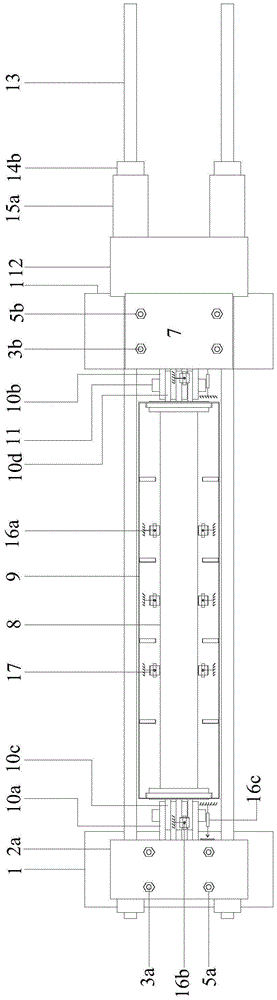

[0038] like Figure 1 to Figure 4 As shown in the figure, a device for studying the performance of CFST bending members under load and corrosion consists of three parts: a loading mechanism, a corrosion mechanism and a measuring mechanism.

[0039]The loading mechanism includes two supports 1 , on which a fixed-end hinge support 2a and a free-end hinge support 2b are respectively provided, and between the fixed-end hinge support 2a and the support 1, a For the steel backing plate 4, a half plate hinge, namely the first plate hinge 10a, is welded on the fixed end hinge support 2a, and a half plate hinge, namely the second plate hinge 10b, is welded on the free end hinge support 2b ; The fixed end hinge support 2a is fixedly connected with the support 1 through the first hinge support fixing rod 3a and the first hinge support fixing rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com