A kind of insulating flame-retardant EPDM rubber hose composition and preparation method thereof

A technology of EPDM rubber and rubber hose, applied in the rubber field, can solve the problems of increased mechanical properties, poor flame retardant properties, hazards, etc., and achieves the effect of compact section, increased reinforcement effect, and increased compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

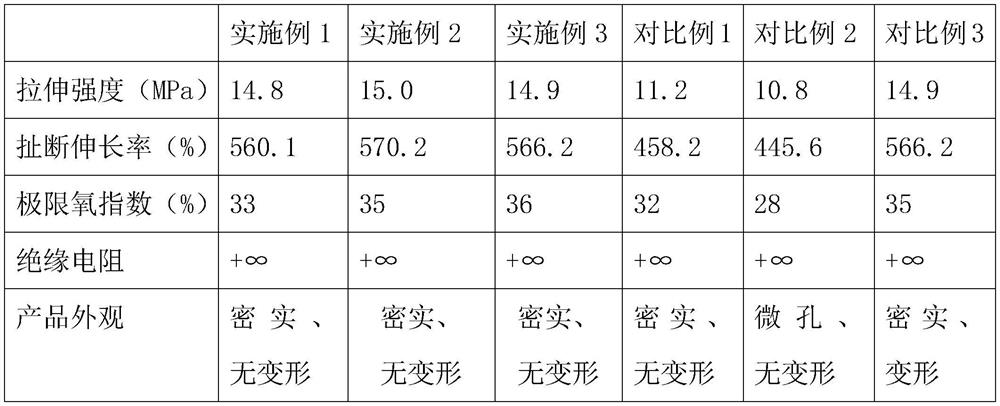

Examples

Embodiment 1

[0030] An insulating flame-retardant EPDM hose composition, by weight fraction, includes the following components:

[0031] EPDM5890F, 100 parts; kaolin, 2 parts; zinc oxide, 3 parts; 1.2 parts of stearic acid; paraffin, 2 parts; antioxidant MB, 1 part; carbon black SP6400A, 50 parts; 10 parts of antimony trioxide; 10 parts of decabromodiphenylethane; paraffin oil, 10 parts; sulfur, 1 part; accelerator BZ, 0.8 parts; accelerator TRA, 1.2 parts; accelerator DM, 0.5 parts; Accelerator TT, 0.5 parts; calcium oxide, 10 parts.

[0032] A preparation method of an insulating flame-retardant rubber hose composition, comprising the steps of:

[0033] (1) Weighing: Weigh the raw materials according to the ratio in the formula;

[0034] (2) raw material pretreatment: the carbon black SP6400A weighed in step (1) was stirred evenly with aluminum hydroxide and paraffin oil, ultrasonically activated for 5 hours, the carbon black SP6400A and aluminum hydroxide were pulled out, and drained f...

Embodiment 2

[0051] An insulating flame-retardant EPDM hose composition, by weight fraction, includes the following components:

[0052] PDM5890F, 100 parts; kaolin, 4 parts; zinc oxide, 5 parts; 2 parts of stearic acid; paraffin, 3 parts; antioxidant MB, 1.5 parts; carbon black SP6400A, 60 parts; 15 parts of antimony trioxide; 25 parts of decabromodiphenylethane; paraffin oil, 15 parts; sulfur, 1.2 parts; accelerator BZ, 0.7 parts; accelerator TRA, 1 part; accelerator DM, 0.4 parts; Accelerator TT, 0.4 parts; calcium oxide, 12 parts.

[0053] The preparation method of an insulating and flame-retardant EPDM hose composition is the same as that in Example 1.

Embodiment 3

[0055] An insulating flame-retardant EPDM hose composition, by weight fraction, includes the following components:

[0056] EPDM5890F, 100 parts; kaolin, 6 parts; zinc oxide, 6 parts; 2.2 parts of stearic acid; paraffin, 4 parts; antioxidant MB, 2 parts; carbon black SP6400A, 70 parts; 20 parts of antimony trioxide; 20 parts of decabromodiphenylethane; 30 parts of paraffin oil; 1.5 parts of sulfur; 0.5 parts of accelerator BZ; 0.8 parts of accelerator TRA; 0.2 parts of accelerator DM; Accelerator TT, 0.2 parts; calcium oxide, 15 parts.

[0057] The preparation method of an insulating and flame-retardant EPDM hose composition is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com