Chlorine replaced polythiophene derivative and solar battery

A polythiophene derivative, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low open circuit voltage, limit energy conversion efficiency, etc., and achieve the effect of high open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

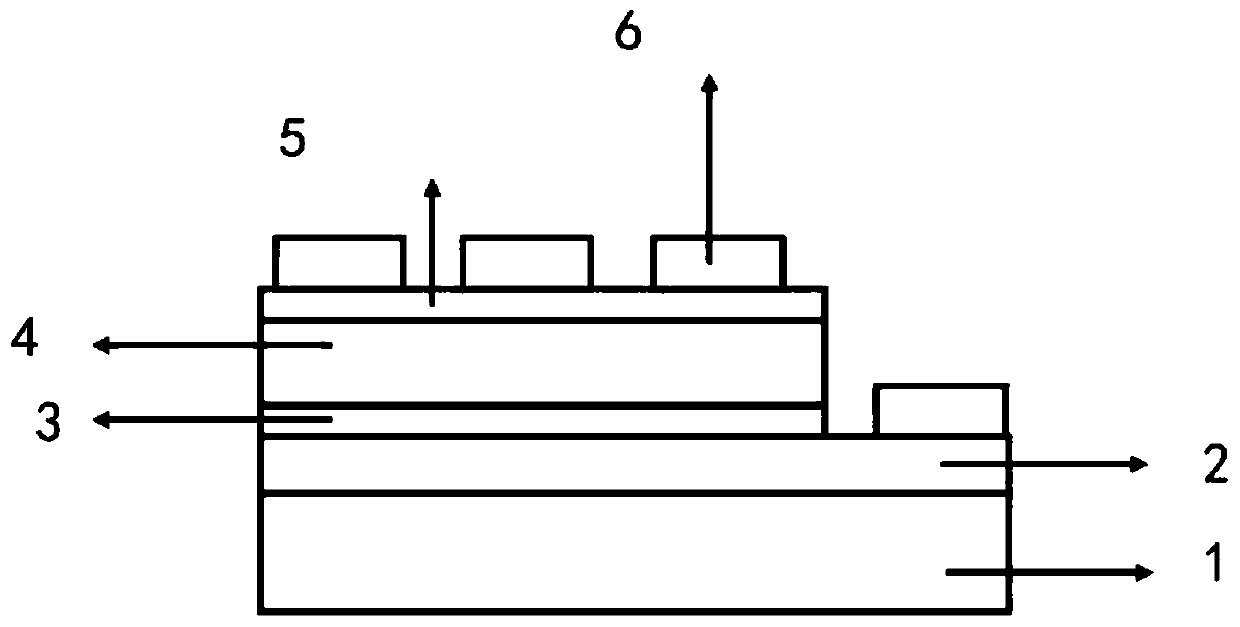

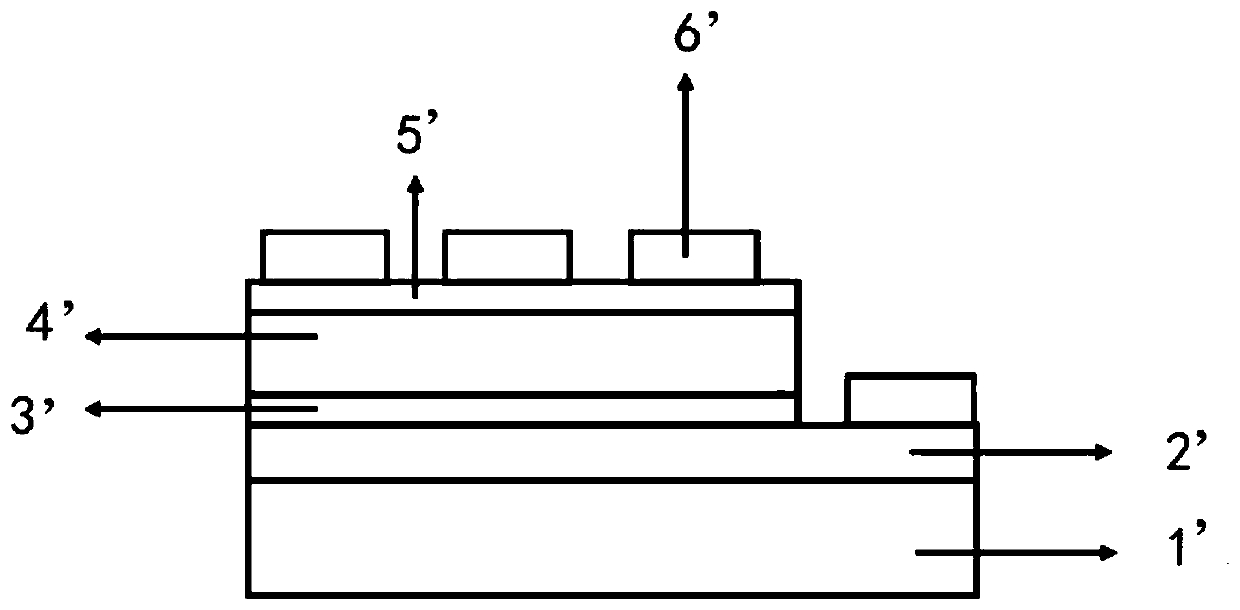

Image

Examples

preparation example Construction

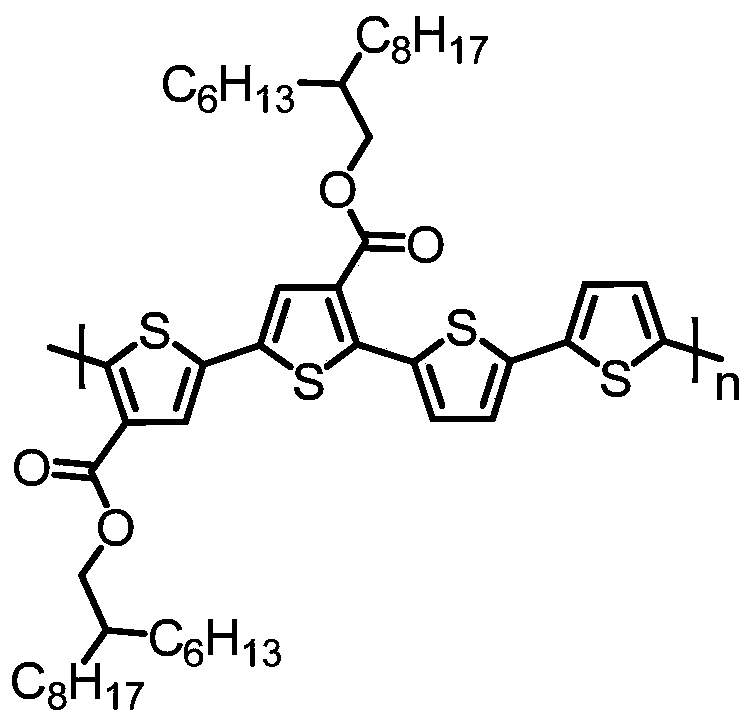

[0025] Preparation of raw materials M1 and M1',:

[0026]

[0027] (M1) and (M1'); wherein R is a branched alkyl chain in the formula (M1), and R is an alkyl chain in the formula (M1').

[0028] Preparation of raw materials N1(II-1)(II-4), N2(II-2)(II-5), N3(II-3)(II-6):

[0029]

[0030] Preparation of product:

[0031]

[0032]

[0033]

Embodiment 1

[0034] Embodiment 1: (2-butyloctyl)-2-bromothiophene-3-carboxylate

[0035]

[0036] 2-Bromo-3-carboxythiophene (1.50g, 7.28mmol), DCC (0.87g, 8.74mmol), DMAP (0.23g, 2.55mmol), 2-butyl-1-octanol (2.70g, 14.50mmol ) was dissolved in 50 mL of dichloromethane and stirred at room temperature for 24 hours. Then it was poured into water, filtered, and the filter cake was washed several times with dichloromethane. The filtrate was collected, washed three times with saturated brine, dried over anhydrous magnesium sulfate, filtered, and the solvent was spin-dried, and the crude product was subjected to silica gel column chromatography (the eluent was petroleum ether (PE): CH 2 Cl 2 =6:1) Purified to obtain colorless liquid (2-butyloctyl)-2-bromothiophene-3-carboxylate. The structural characterization data are as follows: 1 H NMR (CDCl 3 ,400MHz): δ(ppm)=7.92(d,J=1.6Hz,1H),7.52(d,J=1.6Hz,1H),4.14(d,J=5.6Hz,2H),1.75-1.66(m ,1H),1.45-1.19(m,16H),0.85-0.90(m,6H).

Embodiment 2

[0037] Example 2: (2-hexyldecyl)-2-bromothiophene-3-carboxylate

[0038]

[0039] 2-Bromo-3-carboxythiophene (1.50g, 7.28mmol), DCC (0.87g, 8.74mmol), DMAP (0.23g, 2.55mmol), 2-hexyl-1-decanol (3.50g, 14.50mmol) Dissolve in 50 mL of dichloromethane and stir at room temperature for 24 hours. Then it was poured into water, filtered, and the filter cake was washed several times with dichloromethane. The filtrate was collected, washed three times with saturated brine, dried over anhydrous magnesium sulfate, filtered, and the solvent was spin-dried, and the crude product was subjected to silica gel column chromatography (the eluent was petroleum ether (PE): CH 2 Cl 2 =6:1) Purified to obtain colorless liquid (2-hexyldecyl)-2-bromothiophene-3-carboxylate. The structural characterization data are as follows: 1 H NMR (CDCl 3 ,400MHz): δ(ppm)=7.94(d,J=1.6Hz,1H),7.54(d,J=1.6Hz,1H),4.17(d,J=5.6Hz,2H),1.78-1.68(m ,1H),1.46-1.19(m,24H),0.85-0.90(m,6H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com