Method for repairing concrete pavement by using virgin fiber cement-based repairing material

A technology of concrete pavement and primary fiber, which is applied to cohesive pavement paved on site, roads, roads, etc. It can solve the problems of poor interface bonding, poor deformation capacity, and damage to concrete pavement, and achieve excellent crack control ability , good mechanical properties, good integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

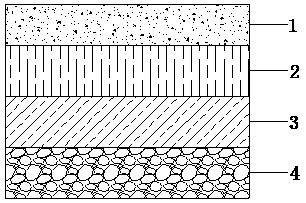

Image

Examples

Embodiment 1

[0031] A method for repairing concrete pavements using native fiber cement-based repair materials, comprising the following steps:

[0032] Step 1. According to the climate temperature and site conditions, design the optimal mix ratio of virgin fiber cement-based composite materials before the construction starts, and conduct experiments to verify the setting time, mechanical strength, fluidity and other indicators. The mix ratio is based on the actual situation Make minor adjustments. The proportion of raw fiber cement-based materials used is: water 280kg / m 3 ; Cement 310kg / m 3 ; fine sand 680kg / m 3 ; Fly ash 700kg / m 3 ; Virgin fiber 28kg / m 3 ;Polycarboxylate superplasticizer 15kg / m 3 ; Binder hydroxypropyl methylcellulose 0.18kg / m 3 ;

[0033] Step 2: Crushing the old cement concrete pavement, that is, breaking the whole cement concrete pavement into pieces at one time through multiple hammer heads or other types of impact equipment, so that the pavement can be transf...

Embodiment 2

[0049] A method for repairing concrete pavements using native fiber cement-based repair materials, comprising the following steps:

[0050] Step 1. According to the climate temperature and site conditions, design the optimal mix ratio of virgin fiber cement-based composite materials before the construction starts, and conduct experiments to verify the setting time, mechanical strength, fluidity and other indicators. The mix ratio is based on the actual situation Make minor adjustments. The proportion of raw fiber cement-based materials used is: water 290kg / m 3 ; Cement 320kg / m 3 ; fine sand 690kg / m 3 ; Fly ash 690kg / m 3 ; Virgin fiber 26kg / m 3 ;Polycarboxylate superplasticizer 12kg / m 3 ; Binder hydroxypropyl methylcellulose 0.16kg / m 3 ;

[0051] Step 2: Crushing the old cement concrete pavement, that is, breaking the whole cement concrete pavement into pieces at one time through multiple hammer heads or other types of impact equipment, so that the pavement can be transf...

Embodiment 3

[0067] A method for repairing concrete pavements using native fiber cement-based repair materials, comprising the following steps:

[0068] Step 1. According to the climate temperature and site conditions, design the optimal mix ratio of virgin fiber cement-based composite materials before the construction starts, and conduct experiments to verify the setting time, mechanical strength, fluidity and other indicators. The mix ratio is based on the actual situation Make minor adjustments. The proportion of raw fiber cement-based materials used is: water 280kg / m 3 ; Cement 310kg / m 3 ; fine sand 680kg / m 3 ; Fly ash 680kg / m 3 ; Virgin fiber 24kg / m 3 ;Polycarboxylate superplasticizer 10kg / m 3 ; Binder hydroxypropyl methylcellulose 0.15kg / m 3 ;

[0069] Step 2: Crushing the old cement concrete pavement, that is, breaking the whole cement concrete pavement into pieces at one time through multiple hammer heads or other types of impact equipment, so that the pavement can be transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com