A carton paper automatic feeding device for a hard strip packaging machine

An automatic feeding and packaging machine technology, applied in the direction of packaging cigarettes, etc., can solve the problems of equipment squeezing cigarettes, poor downward conveying of carton paper, affecting product quality and production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

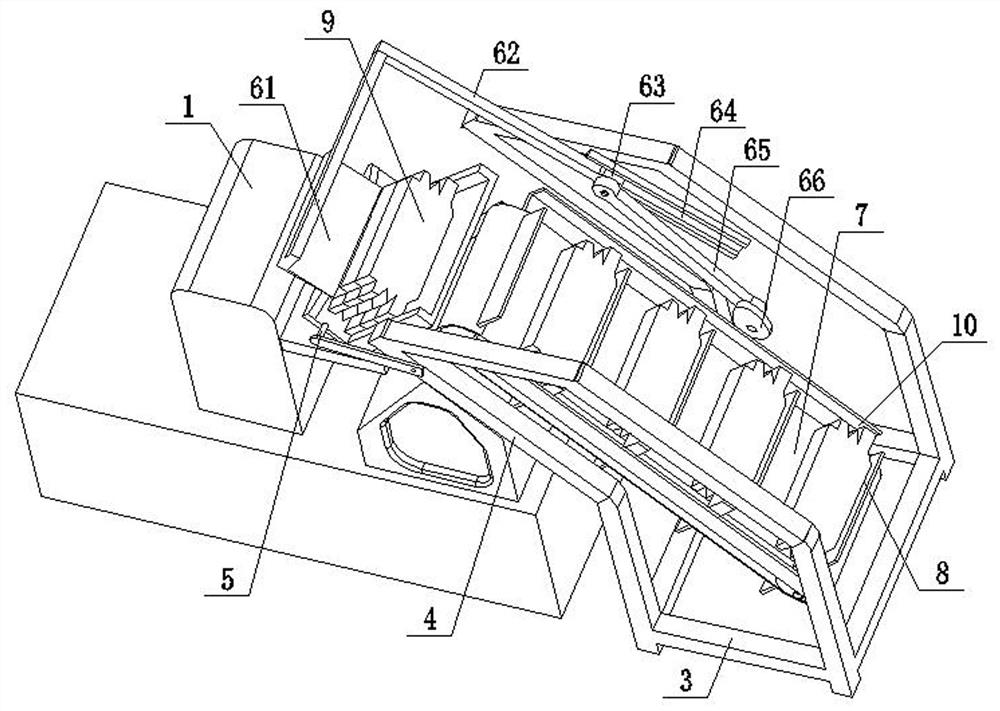

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

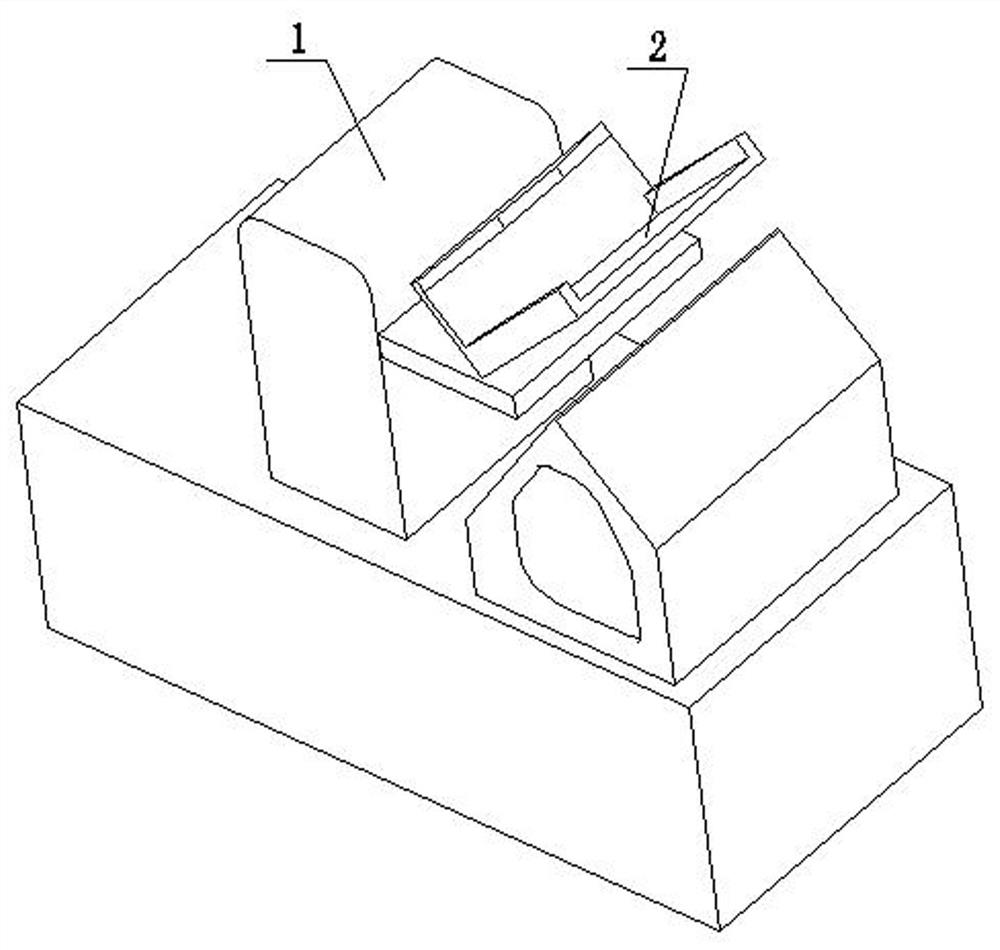

[0021] Such as figure 1 As shown, the CT rigid carton packaging machine 1 needs to continuously draw carton paper from the paper warehouse 2 to pack loose cigarette packs during normal operation. In the warehouse 2, a special person is required to manage it. When it is estimated that it is almost used up, it will be manually loaded again. When the carton paper in the paper warehouse is less or used up during the production process, the carton paper will not be conveyed smoothly or conveyed downward. The deflection in the process causes the equipment to extrude cigarettes, which seriously affects the product quality and production efficiency.

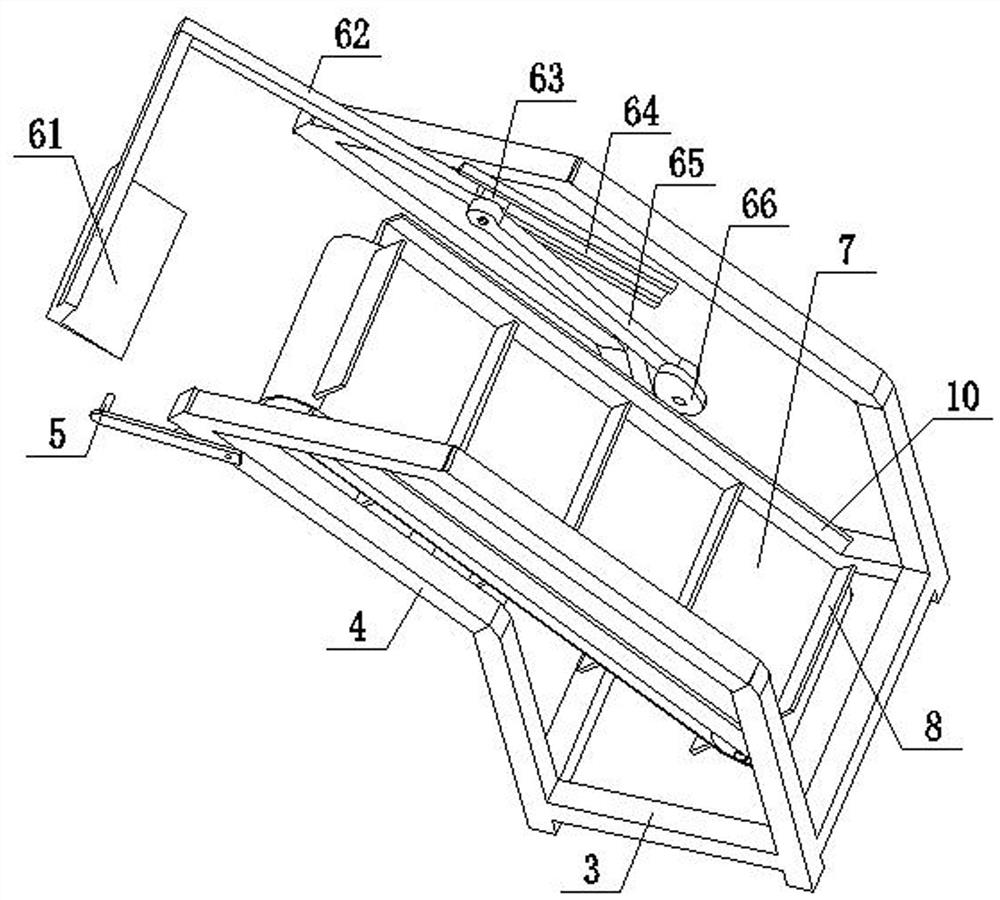

[0022] Such as figure 2 and image 3 As shown, the present invention includes a support frame 3, a foot is provided at the bottom of the support frame 3, an oblique support frame 4 is integrally formed on the top of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com