Method and system for manufacturing microscopic speckle in digital image correlation method by using femtosecond laser

A femtosecond laser and digital image technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of large influence of speckle surface properties, change of physical and chemical properties, large speckle, etc., and achieve the diameter of speckle. and density controllable, high repeatability, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Clean the surface of the sample to be made with absolute ethanol, and dry it, select the sample to be made as the Fe-Ni plate weld, and the size of the sample to be made is 12mm×10mm×3mm (length×width×thickness) );

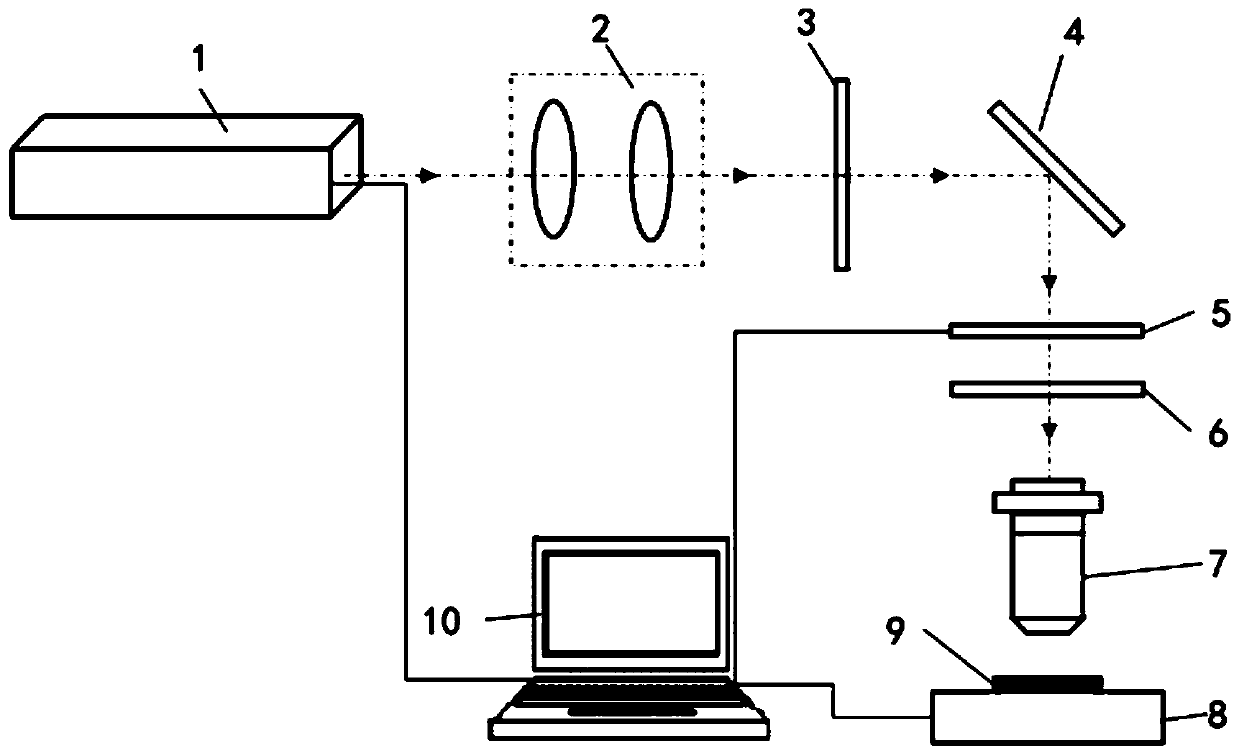

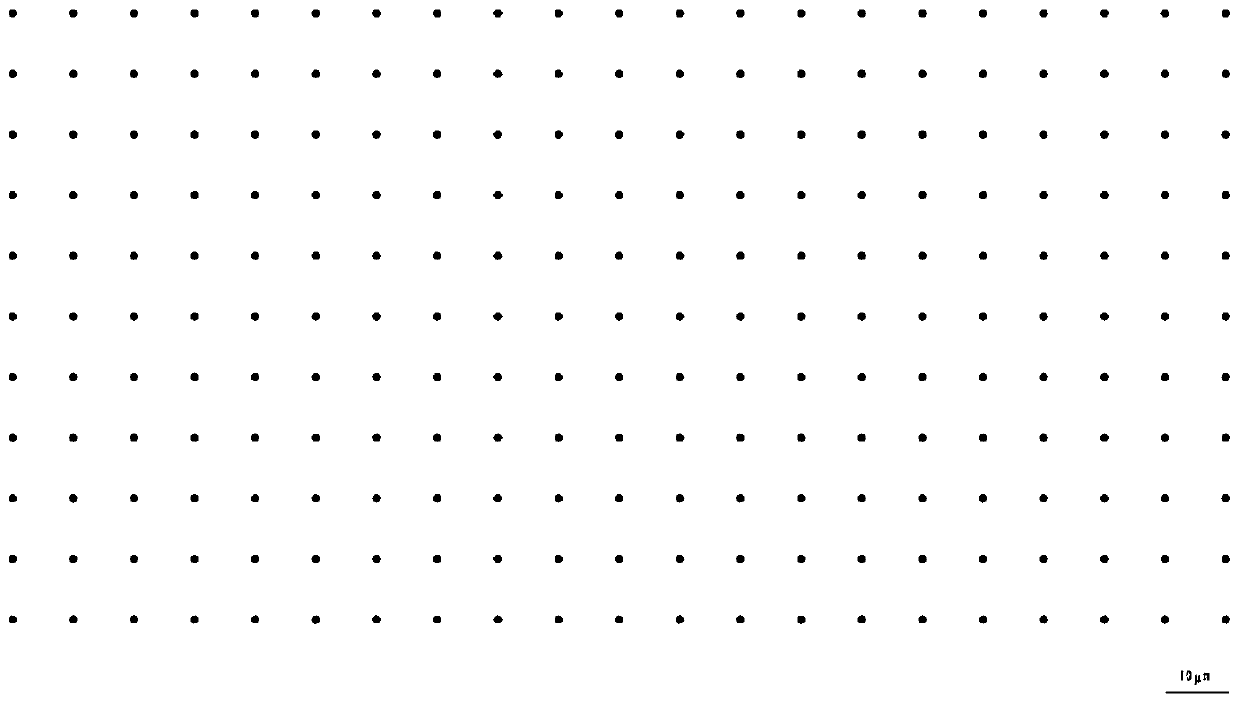

[0029] (2) According to the requirements, determine that the diameter of the microscopic speckle to be produced is 1 μm, the speckle field is a rectangular array, and the pitch is 10 μm, and the ideal speckle field is drawn as figure 2 , and generate a microscopic speckle field according to the determined speckle diameter, speckle density and speckle field type, and obtain the motion trajectory of the three-dimensional workbench according to the coordinates of the microscopic speckle in the microscopic speckle field;

[0030] (3) The femtosecond laser beam is incident on the sample to be produced, and the sample to be produced is placed on the three-dimensional workbench, so that the three-dimensional workbench moves according to the motion track of st...

Embodiment 2

[0033] (1) Clean the surface of the sample to be made with absolute ethanol, and dry it, select the sample to be made as a Si sheet, and the size of the sample to be made is 10mm×10mm×1mm (length×width×thick);

[0034] (2) According to the requirements, the microscopic speckle diameter is selected as 1 μm, the microscopic speckle field is a rectangular array, and the microscopic speckle spacing is 10 μm, and the microscopic speckle field is generated according to the determined speckle diameter, speckle density and speckle field type , according to the coordinates of the microscopic speckle in the microscopic speckle field, the motion trajectory of the three-dimensional workbench is obtained;

[0035] (3) The femtosecond laser beam is incident on the sample to be produced, and the sample to be produced is placed on the three-dimensional workbench, so that the three-dimensional workbench moves according to the motion track of step (2), and the production of the microscopic speck...

Embodiment 3

[0038] (1) Clean the surface of the sample to be made with absolute ethanol, and dry it, select the sample to be made as a Cu plate, and the size of the sample to be made is 10mm×1mm (diameter×thick);

[0039] (2) According to the requirements, the microscopic speckle diameter is selected as 1 μm, the microscopic speckle field is a rectangular array, and the microscopic speckle spacing is 10 μm, and the microscopic speckle field is generated according to the determined speckle diameter, speckle density and speckle field type , according to the coordinates of the microscopic speckle in the microscopic speckle field, the motion trajectory of the three-dimensional workbench is obtained;

[0040] (3) The femtosecond laser beam is incident on the sample to be produced, and the sample to be produced is placed on the three-dimensional workbench, so that the three-dimensional workbench moves according to the motion track of step (2), and the production of the microscopic speckle on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com