Preparation method of high-strength antioxidation chitosan/polydopamine composite hydrogel

A technology of composite hydrogel and polydopamine, applied in the field of natural polymer chemistry, can solve the problems of weak mechanical properties, no anti-oxidation, limited application scope, etc., and achieves low cost, excellent product performance, good anti-oxidation and Effects of pH Responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A physically cross-linked chitosan hydrogel, the preparation method of which is as follows:

[0037] Prepare 95 grams of LiOH, KOH, urea and H 2 O Alkaline solvent mixed at a mass ratio of 5:7:8:80, 5 g of chitosan powder was added to the above-mentioned alkaline solvent and stirred for 5 min to disperse, frozen at -30°C, and then stirred and thawed at room temperature. The completely thawed solution was centrifuged at 5° C. at 7000 rpm for 10 minutes to defoam to obtain a clear and transparent 5 wt % chitosan alkaline solution. Place it in denatured alcohol for 24 hours to regenerate, and wash with water to obtain physically cross-linked chitosan hydrogel. Using a universal testing machine, the test rate is 0.5 mm / min, and the hydrogel compressive strength is measured to be 2.4 MPa, and the breaking strain is 82%.

Embodiment 2

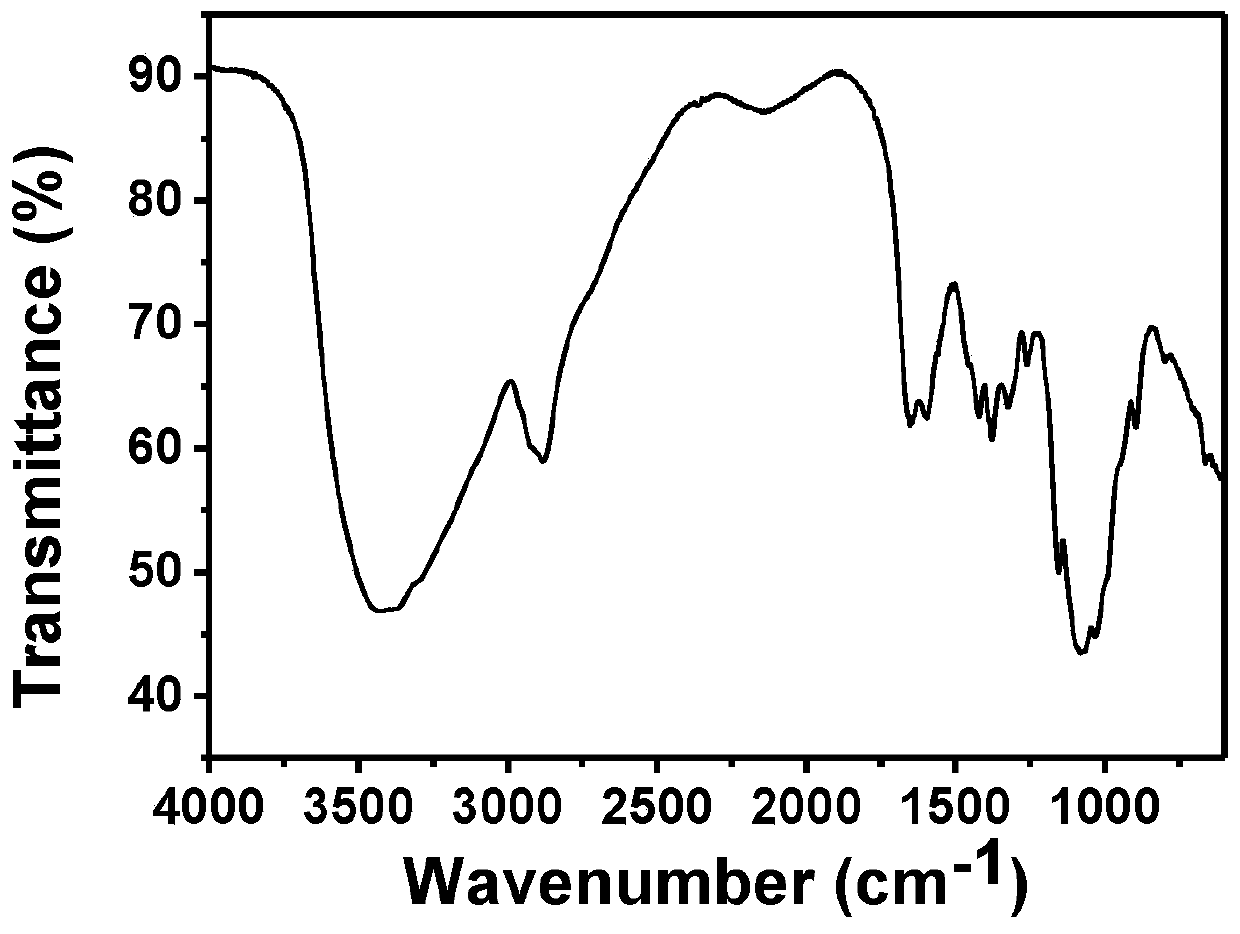

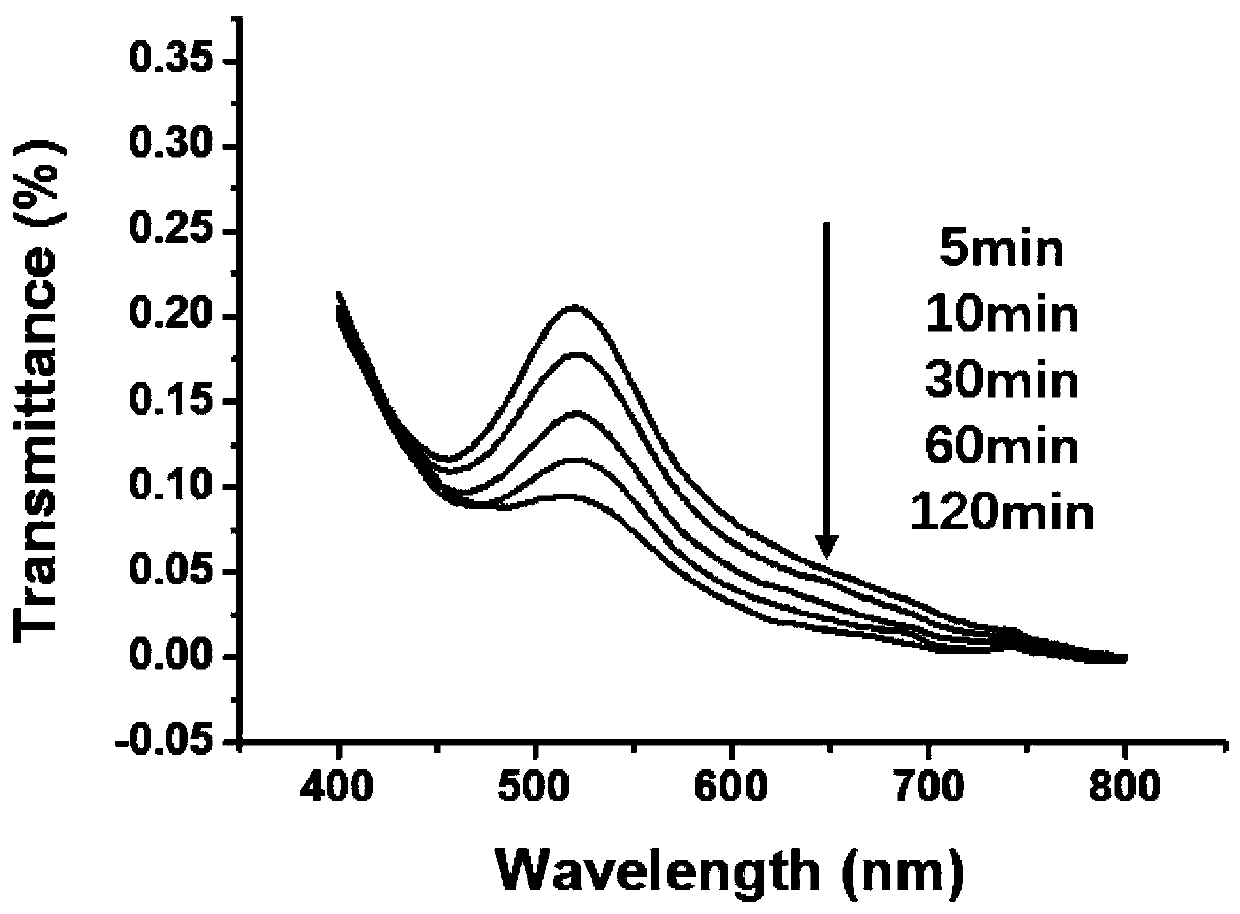

[0039] A physically cross-linked chitosan / polydopamine composite hydrogel, the preparation method of which is as follows:

[0040] Prepare 95 grams of LiOH, KOH, urea and H2 O Alkaline solvent mixed at a mass ratio of 5:7:8:80, 5 g of chitosan powder was added to the above-mentioned alkaline solvent and stirred for 5 min to disperse, frozen at -30°C, and then stirred and thawed at room temperature. The completely thawed solution was centrifuged at 5° C. at 7000 rpm for 10 minutes to defoam to obtain a clear and transparent 5 wt % chitosan alkaline solution. Then add 0.5 gram of dopamine hydrochloride in this chitosan alkaline solution, stir at room temperature for 30 minutes, centrifugal defoaming, place in 5 ℃ of refrigerators and refrigerate for 24 hours, obtain dark brown chitosan / polydopamine alkaline fluid, place it It was regenerated in industrial alcohol for 24 hours, and washed with water to obtain a physically cross-linked chitosan / polydopamine composite hydrogel. Us...

Embodiment 3

[0042] A chitosan hydrogel of physicochemical crosslinking, its preparation method is as follows:

[0043] Prepare 95 grams of LiOH, KOH, urea and H 2 O Alkaline solvent mixed at a mass ratio of 5:7:8:80, 5 g of chitosan powder was added to the above-mentioned alkaline solvent and stirred for 5 min to disperse, frozen at -30°C, and then stirred and thawed at room temperature. The completely thawed solution was centrifuged at 5° C. at 7000 rpm for 10 minutes to defoam to obtain a clear and transparent 5 wt % chitosan alkaline solution. Then add 1.5mL epichlorohydrin to the chitosan alkaline solution, stir at room temperature for 30 minutes, centrifuge and defoam, and place it in a 5°C refrigerator for 24 hours to obtain the chitosan alkaline pregel, which is placed in Regenerated in industrial alcohol for 24 hours, and washed with water to obtain physicochemically cross-linked chitosan hydrogel. Using a universal testing machine, the test rate is 0.5 mm / min, and the hydrogel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com