Two-phase flow semi-dry deacidification device for flue gas

A semi-dry method and flue gas technology, applied in the field of pollution treatment, can solve problems such as loss of dynamic balance, and achieve the effect of benefiting flue gas temperature, increasing specific surface area, and increasing the chance of contact reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

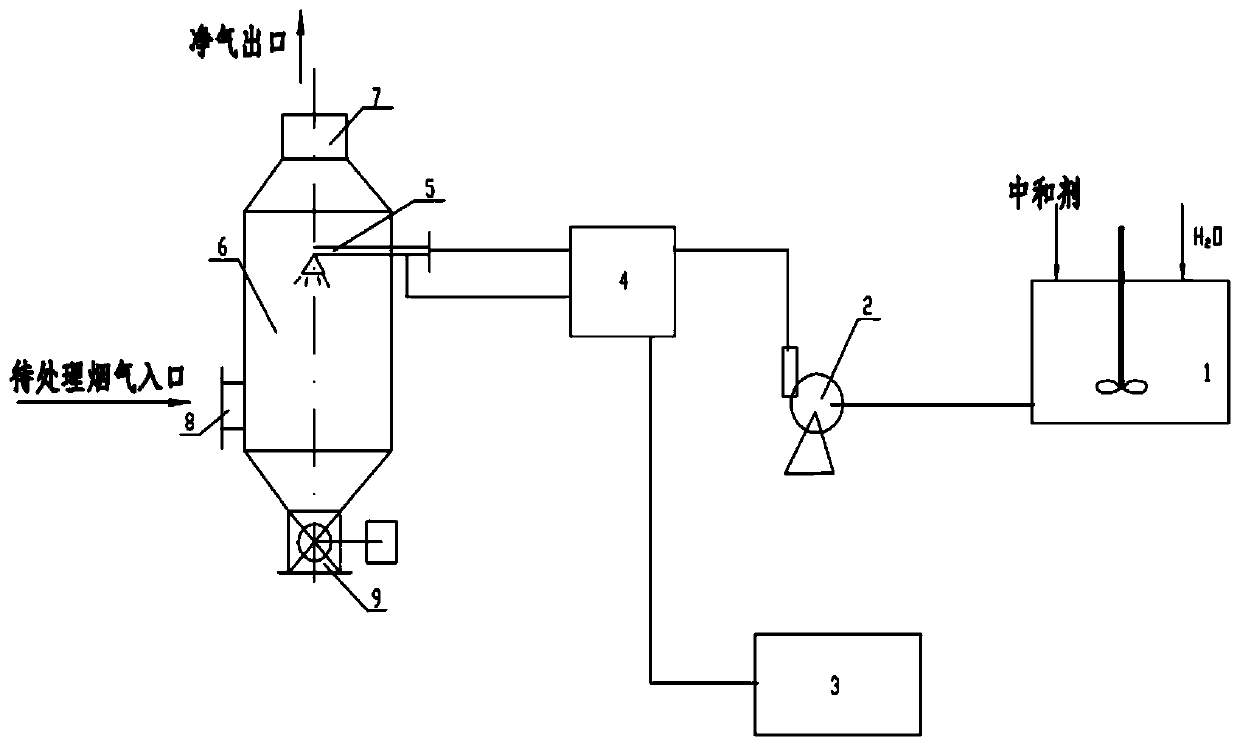

[0024] figure 1 It is a structural schematic diagram of the spray gun unit of the present invention, figure 2 It is a structural schematic diagram of the present invention, as shown in the figure: the two-phase flow semi-dry flue gas deacidification device of this embodiment includes a reaction tower 6, a spray gun unit 5 arranged in the reaction tower, and a compressed gas supply unit 3. The neutralizing agent supply unit and the control unit 4; the spray gun unit 5 is provided with a multi-stage system for atomizing and spraying the liquid neutralizing agent entering the spray gun unit 5 and deacidifying the flue gas in the reaction tower Atomization structure; the spray gun unit 5 is cylindrical with a sealed structure, and the setting of the multi-stage atomization structure in the spray gun unit 5 facilitates the formation of tiny particles through multiple atomization of the liquid neutralizer, increasing the liquid neutralization The specific surface area of the age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com