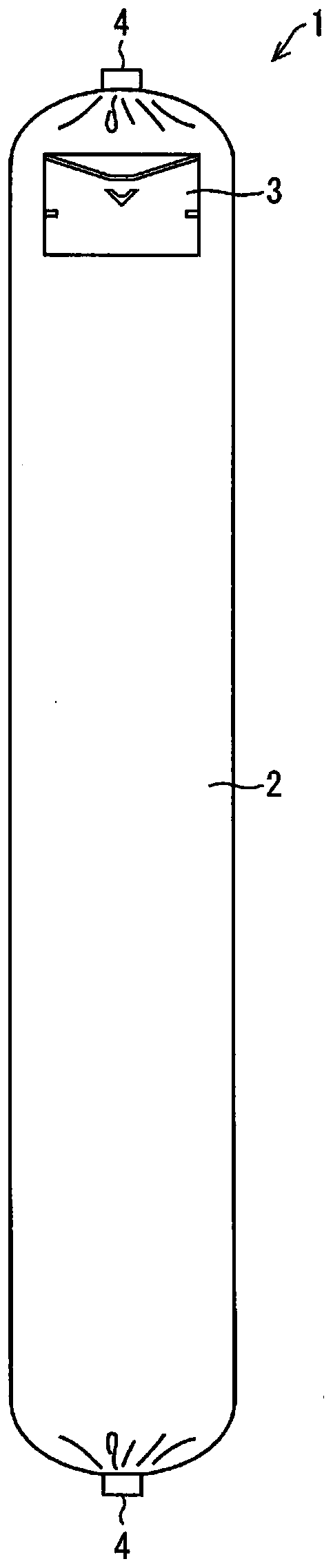

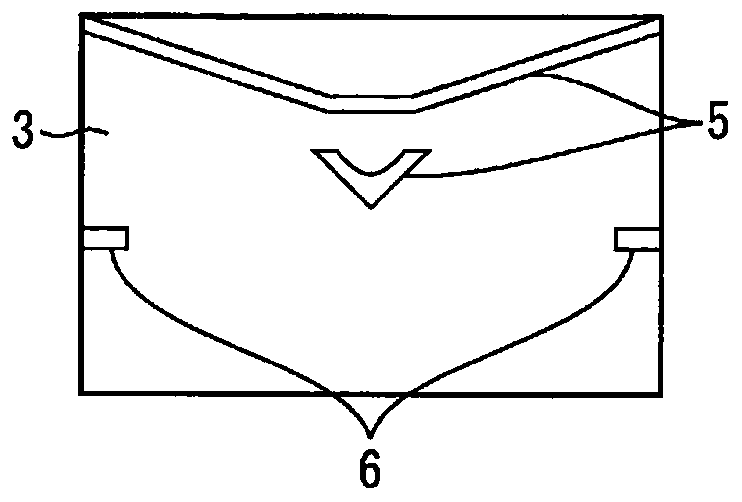

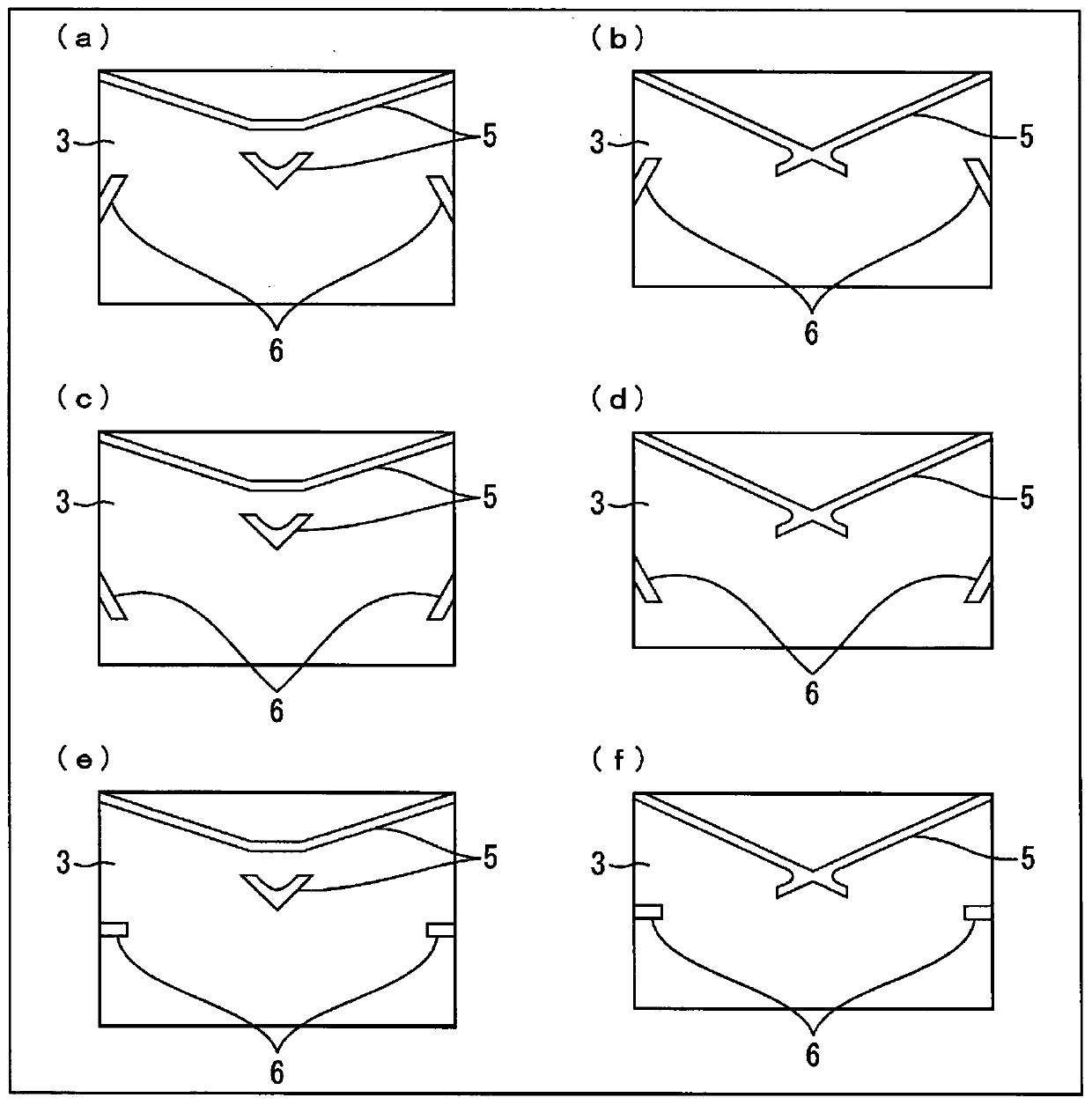

Package with opening piece

A packaging body and unsealing sheet technology, which is applied in the field of packaging with an opening sheet, can solve problems such as breakage of the opening sheet and unsealing of the packaging body, and achieve the effect of reliable opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (Manufacture of base film)

[0070] A total of 8 parts by mass of acetyl lemon was blended into a copolymer (100 parts by mass) having a monomer charge mass ratio (VD / VC) of 81 / 19 during polymerization of vinylidene chloride (VD) and vinyl chloride (VC). tributyl sebacate (ATBC), dibutyl sebacate (DBS) and epoxidized vegetable oil, further add a total of 1.4 parts by mass of epoxy-containing polymers, surfactants, stearic acid amide and silicon dioxide , and a polyvinylidene chloride-based resin was obtained. Next, the obtained polyvinylidene chloride-based resin was melt-extruded using an extruder screw having a diameter of 90 mm, and then biaxially stretched to obtain a base material film.

[0071] (Manufacture of films for opening sheets)

[0072] A total of 8 parts by mass of acetyl lemon was blended into a copolymer (100 parts by mass) having a monomer charge mass ratio (VD / VC) of 80 / 20 during polymerization of vinylidene chloride (VD) and vinyl chloride (VC). T...

Embodiment 2

[0078] In the production of the film for an opening sheet, the film a was further subjected to a tension heat treatment at 80° C. for 1 minute to obtain a film c for an opening sheet with a total thickness of 80 μm (two films with a thickness of 40 μm overlapped).

[0079] The base material film and the packaging body with an opening sheet were produced in the same manner as in Example 1.

Embodiment 3

[0081] In the production of the film for an opening sheet, the film a was further subjected to a tension heat treatment at 100° C. for 1 minute to obtain a film d for an opening sheet with a total thickness of 80 μm (two films with a thickness of 40 μm overlapped).

[0082] The base material film and the packaging body with an opening sheet were produced in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com