Method and drainage structure for preventing and treating collapsible loess subsidence

A technology of collapsible loess and waterproof materials, which is applied in the field of methods and drainage structures, and the prevention and control of collapsible loess subsidence. It can solve problems such as large noise and vibration, limited reinforcement effect, and difficult compaction in deep layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

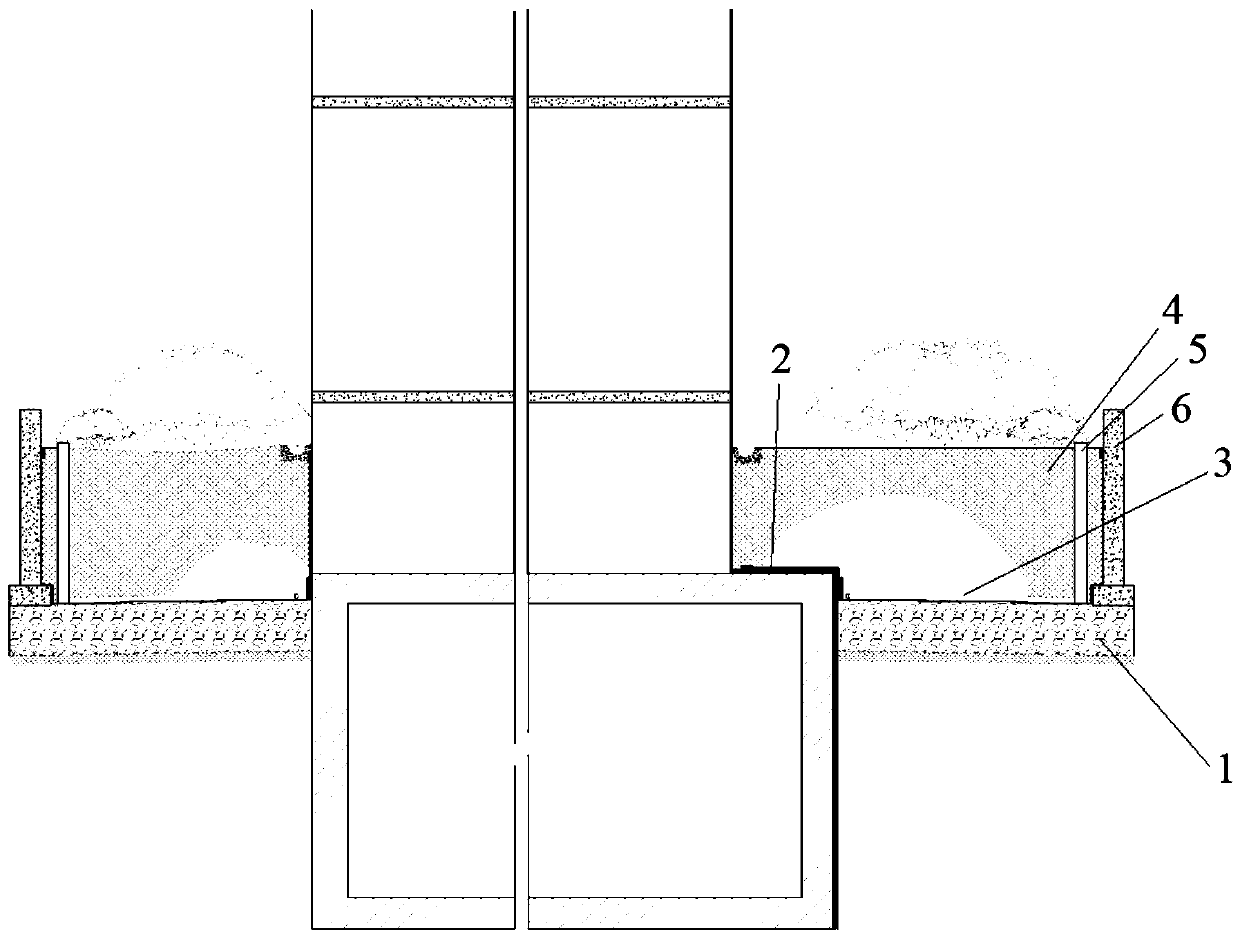

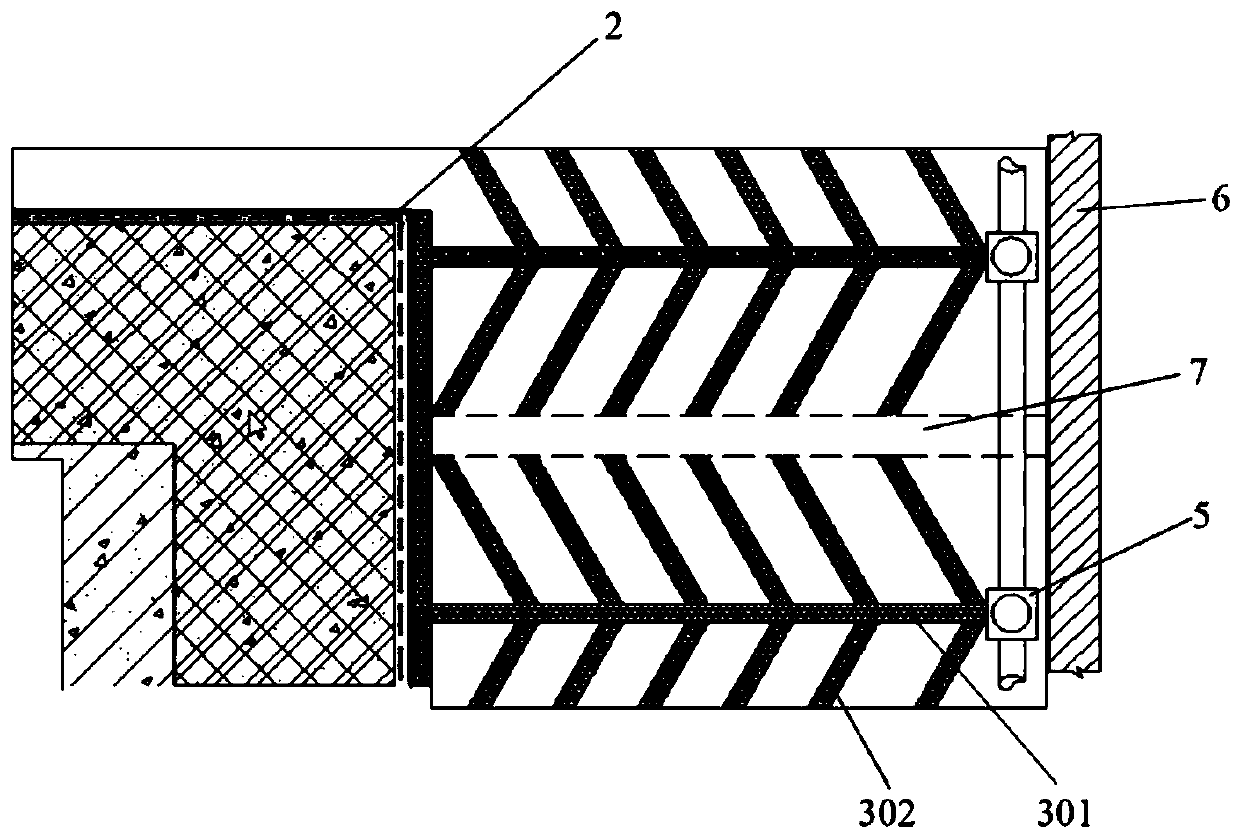

[0038] Such as figure 1 and figure 2 As shown, this embodiment mainly focuses on the anti-seepage and waterproof of the outdoor site of the building. First of all, within the construction scope of the outdoor site, the ground elevation is about 1.5-2 meters below to determine the work site, and the sub-bearing layer of the work site is replaced with 300-500mm thick and 93% dense replacement soil 1 to strengthen the foundation , improve bearing capacity. A reinforced concrete wall 6 is arranged on the side of the work site, and the bottom of the reinforced concrete wall 6 can extend below the replacement soil layer, or can be directly built on the replacement soil layer. In this embodiment, the filling soil 1 is notoginseng ash soil, and the volume ratio of quicklime to plain soil is 3:7. The filling soil 1 itself has a certain function of waterproofing and strengthening the foundation. The immature quicklime absorbs water when it meets water, which reduces the water conten...

Embodiment 2

[0045] The present invention also provides a method for preventing the subsidence of collapsible loess, comprising the following steps:

[0046] Step S101: according to the ground elevation, determine the working site downwards into the self-weight collapsible loess layer;

[0047] Step S102: laying replacement soil on the lower bearing layer of the work site;

[0048] Step S103: laying a waterproof material on the replacement soil, preferably an anti-seepage waterproof geotextile;

[0049] Step S104: horizontally laying a permeable blind pipe on the waterproof material. The permeable blind pipe includes a permeable main pipe and a plurality of permeable branch pipes connected to the permeable main pipe. The permeable main pipe is connected to the rainwater well, and the permeable branch pipe and the permeable main pipe are laid vertically or obliquely;

[0050] Step S105: After laying the permeable blind pipe, backfill the working site to the ground level.

[0051] The work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com