Vertical type flow-line forming method for PCCP cores

An assembly line and forming method technology, which is applied in the direction of ceramic forming machines, auxiliary forming equipment, manufacturing tools, etc., can solve the problems of great influence of product quality interference factors, no breakthrough improvement, and high utilization rate of cranes, so as to reduce human interference Influenced by various factors, significant production economic benefits and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0034] A kind of pipeline type PCCP tube core vertical forming method, comprises the steps:

[0035] 1) Design an assembly line suitable for PCCP die molding according to capacity requirements:

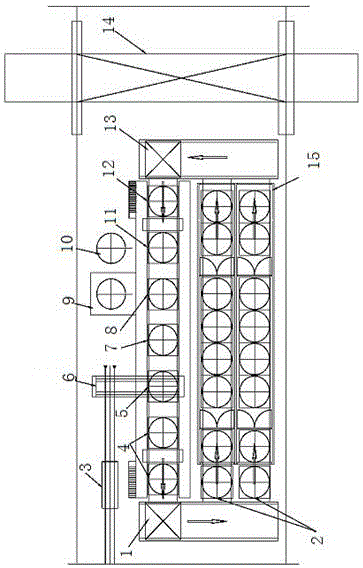

[0036] refer to figure 1 , the assembly line in this embodiment includes 1 production line and 2 maintenance lines, and the production line is provided with demoulding station 11, mold cleaning, inner mold and base cleaning, oiling station 8, outer mold cleaning, oiling station 9, Top cover cleaning, oiling station 10, mold loading station 7, tube core concrete pouring station 5 and plastering inspection station 4, the curing line is equipped with static curing station 2 and steam curing kiln 15, steam curing kiln 15 is from the left To the right, set the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com