Thermoplastic vulcanized rubber nano composite material and preparation method thereof

A nano-composite material, thermoplastic vulcanization technology, applied in the field of nano-composite materials, can solve the problems of polyamide not entering the interlayer in time, product performance impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

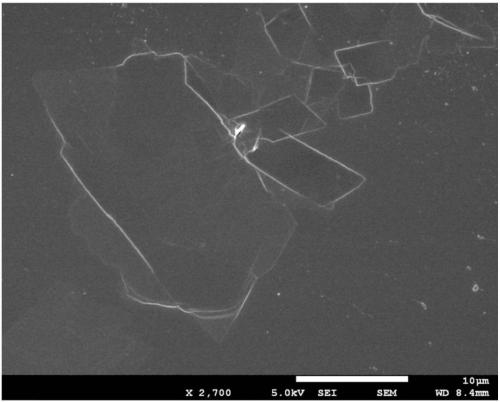

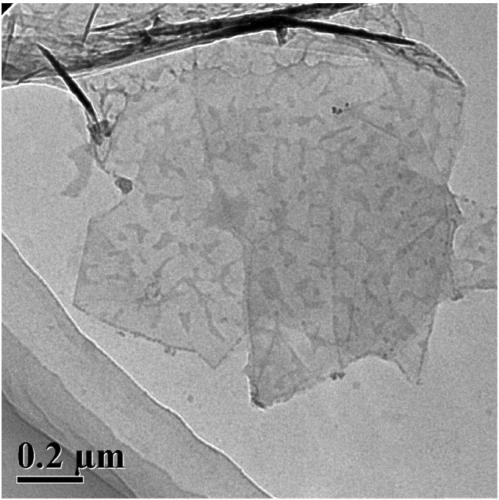

Image

Examples

Embodiment 1

[0101] In this embodiment, the thermoplastic vulcanizate is NBR / PP, wherein the rubber-to-plastic ratio is 70 / 30, the mass ratio of nanomaterials to thermoplastic vulcanizate is 2:100, the liquid medium used is water, and the auxiliary agent used is tamarind Polysaccharide glue, the nano material that adopts is layered nano montmorillonite, the antiaging agent that adopts is tris (2,4-di-tert-butylphenyl) phosphite, prepares nano composite material according to the following method:

[0102] (1) Stir the liquid medium, and at the same time add nanomaterials at a speed of 8.1g / min for continuous stirring and disperse evenly, the weight ratio of liquid medium to nanomaterials is 16:1;

[0103] (2) Add additives in batches or at a time to the continuously stirring solution of step (1) at a speed of 0.1g / min to obtain a paste, the consistency of which is 65mm, and the additives and nanomaterials The weight ratio is 20:1;

[0104] (3) mixing the paste obtained in step (2) with the...

Embodiment 2

[0109] In this embodiment, the thermoplastic vulcanizate is NBR / PP, wherein the rubber-to-plastic ratio is 20 / 80, the mass ratio of nanomaterials to thermoplastic vulcanizate is 10:100, and the liquid medium used is isobutanol and water, isobutanol The mass ratio with water is 1:9, the additives used are aliphatic sulfonates and sulfonaphthalene sulfonates, the weight ratio is 1:1, the nanomaterials used are kaolin, and the anti-aging agents used are anti-aging agents. Oxygen 1035, prepare nanocomposites according to the following method:

[0110] (1) Stir the liquid, and at the same time add nanomaterials at a speed of 20g / min for continuous stirring to disperse evenly, and the weight ratio of the liquid medium to the nanomaterials is 100:1;

[0111] (2) Add auxiliary agent to the continuous stirring solution of step (1) with the speed of 5g / min, obtain paste, the consistency of described paste is 26mm, and the weight ratio of described auxiliary agent and nano material is 10...

Embodiment 3

[0117] In this embodiment, the thermoplastic vulcanizate is NBR / PP, wherein the rubber-to-plastic ratio is 50 / 50, the mass ratio of nanomaterials to thermoplastic vulcanizate is 1:10, the liquid medium used is water, and the auxiliary agent used is polystyrene Sodium ethylene sulfonate, the nanomaterials adopted are Al / Mg-LDHs and nano-montmorillonite, the mass ratio is 1:5, and the nanocomposite is prepared according to the following method:

[0118] (1) Stir the liquid medium, and at the same time add nanomaterials at a speed of 0.01g / min for continuous stirring to disperse evenly, and the weight ratio of liquid medium to nanomaterials is 0.1:1;

[0119] (2) add auxiliary agent in the continuous stirring solution of step (1) with the speed of 1.5g / min, obtain paste, the consistency of described paste is 61mm, and the weight ratio of described auxiliary agent and nanometer material is 4.5:1;

[0120] (3) mixing the paste obtained in step (2) with thermoplastic vulcanizate to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Consistency | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com