High-filling flexible boron nitride composite film material, high-filling flexible boron nitride copper-clad laminate and preparation methods of high-filling flexible boron nitride composite film material and high-filling flexible boron nitride copper-clad laminate

A boron nitride copper clad laminate and composite thin film technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, liquid chemical plating, etc., can solve the problems of difficulty in obtaining large sheets and poor flexibility, etc. To achieve the effect of broad application prospects, good flexibility, and effective thermal conduction paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment provides a highly filled flexible boron nitride composite film material, a highly filled flexible boron nitride copper clad laminate and a patterned copper clad laminate. Obtained by the following preparation method.

[0066] (1) Preparation of highly filled flexible boron nitride composite thin film materials

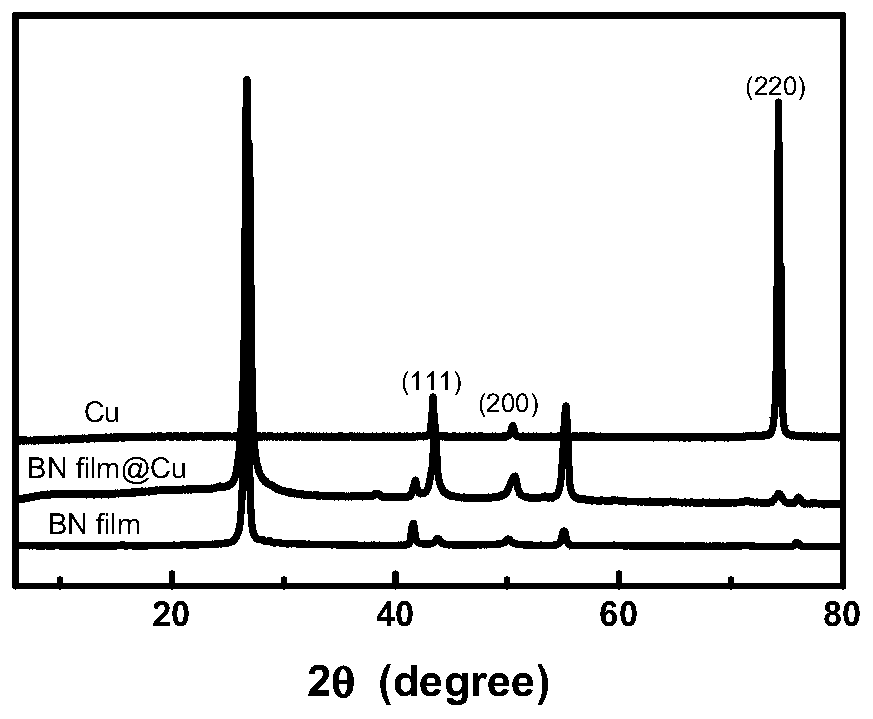

[0067] Ultrasonic disperse 100 parts of hexagonal boron nitride (h-BN) in 1000 parts of dihydromyricetin-ethanol solution with a mass concentration of 50 mg / ml, stir at room temperature for 24 hours, filter, and vacuum dry at 70°C for 12 hours to obtain dihydromyricetin Myricetin modified boron nitride BN@DMY.

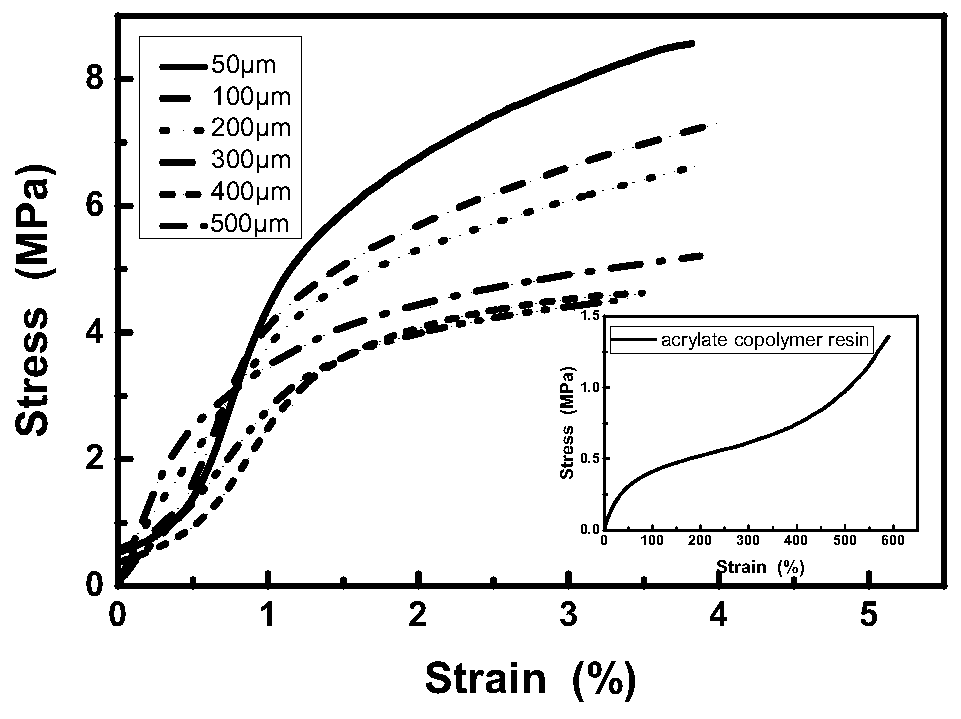

[0068] Dissolve 20 parts of high molecular weight acrylate copolymer resin (molecular weight: 500,000, Tg: 8.6°C) in N-methylpyrrolidone with a mass concentration of 6.2%, and then disperse 94 parts of BN@DMY in it, BN@DMY The mass ratio to the high molecular weight acrylate copolymer resin was 4.7 / 1, mechanically stirred at room temper...

Embodiment 2

[0080] This embodiment provides a highly filled flexible boron nitride composite film material, a highly filled flexible boron nitride copper clad laminate and a patterned copper clad laminate. Obtained by the following preparation method.

[0081] (1) Preparation of highly filled flexible boron nitride composite thin film materials

[0082] The method of modifying hexagonal boron nitride with dihydromyricetin is consistent with Example 1.

[0083] Dissolve 20 parts of high molecular weight acrylate copolymer resin (molecular weight: 500,000, Tg: 8.6°C) in N-methylpyrrolidone with a mass concentration of 6.2%, and then disperse 130 parts of BN@DMY in it, BN@DMY The mass ratio with the high molecular weight acrylate copolymer resin is 6.5 / 1, and the rest are consistent with Example 1.

[0084] (2) Preparation of highly filled flexible boron nitride copper clad laminates and patterned copper clad laminates

[0085] In the preparation process of highly filled flexible boron ni...

Embodiment 3

[0088] This embodiment provides a highly filled flexible boron nitride composite film material, a highly filled flexible boron nitride copper clad laminate and a patterned copper clad laminate. Obtained by the following preparation method.

[0089] (1) Preparation of highly filled flexible boron nitride composite thin film materials

[0090] The method of modifying hexagonal boron nitride with dihydromyricetin is consistent with Example 1.

[0091] Dissolve 20 parts of high molecular weight acrylate copolymer resin (molecular weight: 500,000, Tg: 8.6°C) in N-methylpyrrolidone with a mass concentration of 6.2%, and then disperse 80 parts of BN@DMY in it, BN@DMY The mass ratio with the high molecular weight acrylate copolymer resin is 4 / 1, and the rest are consistent with Example 1.

[0092](2) Preparation of highly filled flexible boron nitride copper clad laminates and patterned copper clad laminates

[0093] In the preparation process of highly filled flexible boron nitrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com