A low-temperature sintered microwave dielectric ceramic material and its preparation method

A technology of microwave dielectric ceramics and low-temperature sintering, which is applied in chemical instruments and methods, inorganic chemistry, tungsten compounds, etc., and can solve problems such as long holding time, limited application, and high sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

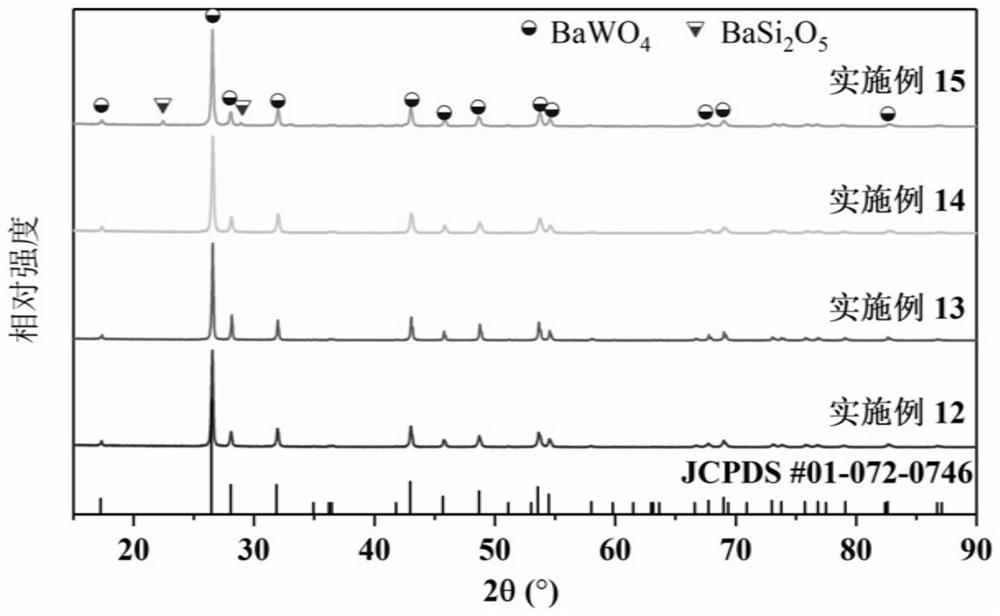

[0015] The present invention is further described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] Material composition according to the present invention of formula BaWO 4 -xM 2 CO 3 -yBaO-zB 2 O 3 -wSiO 2 , X = 0 ~ 0.2mol, y = 0 ~ 0.05mol, z = 0 ~ 0.2mol, w = 0 ~ 0.1mol wherein M is an alkali metal ion Li + K + NA + And x, y, z, w can not be zero at the same time, the present invention is by the solid phase reaction material can be prepared.

[0017] The BaWO 4 Microwave dielectric material producing low-temperature sintering ceramic material groups are: BaCO 3 , WO 3 , Li 2 CO 3 K 2 CO 3 NA 2 CO 3 , B 2 O 3 SiO 2 . This material can be obtained by a solid phase reaction method, particularly steps like the above-described steps.

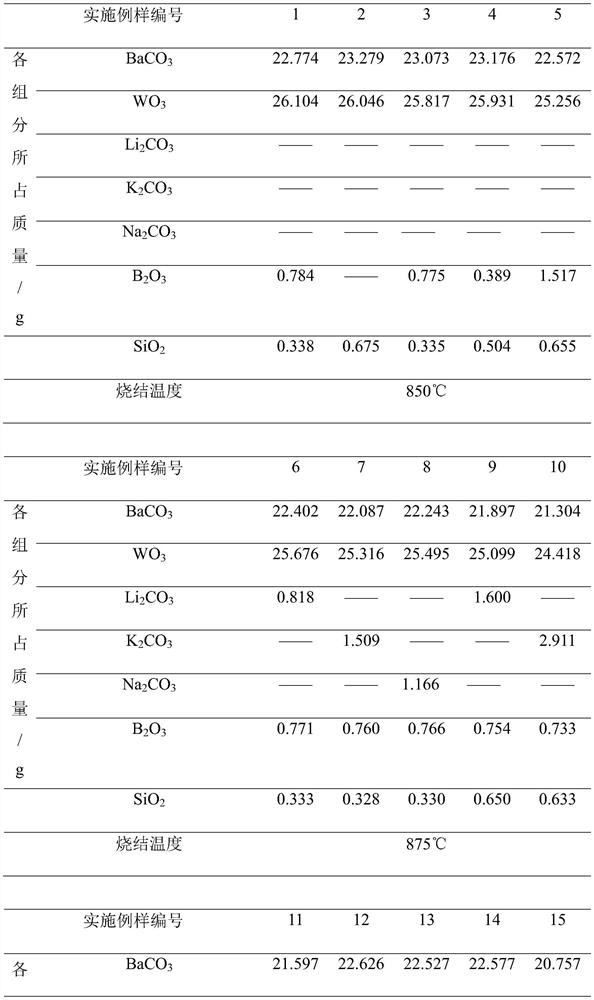

[0018] Specific components and microwave dielectric properties embodiment is as follows

[0019]

[0020]

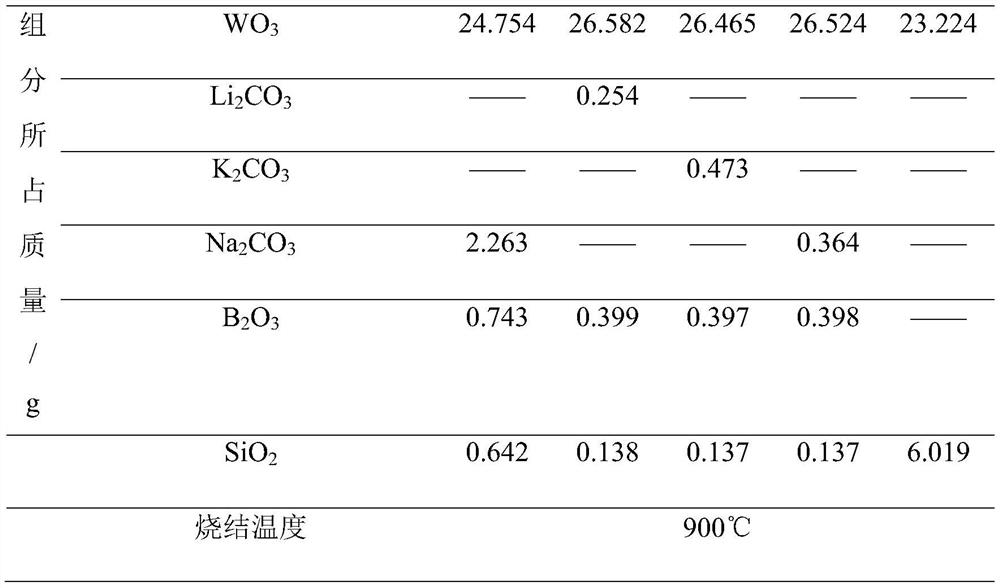

[0021]

[0022]

[0023] Encompasses the form data and the results of Example cooked ingredients ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency temperature coefficient | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com