Binderless A-type molecular sieve particles and preparation method thereof

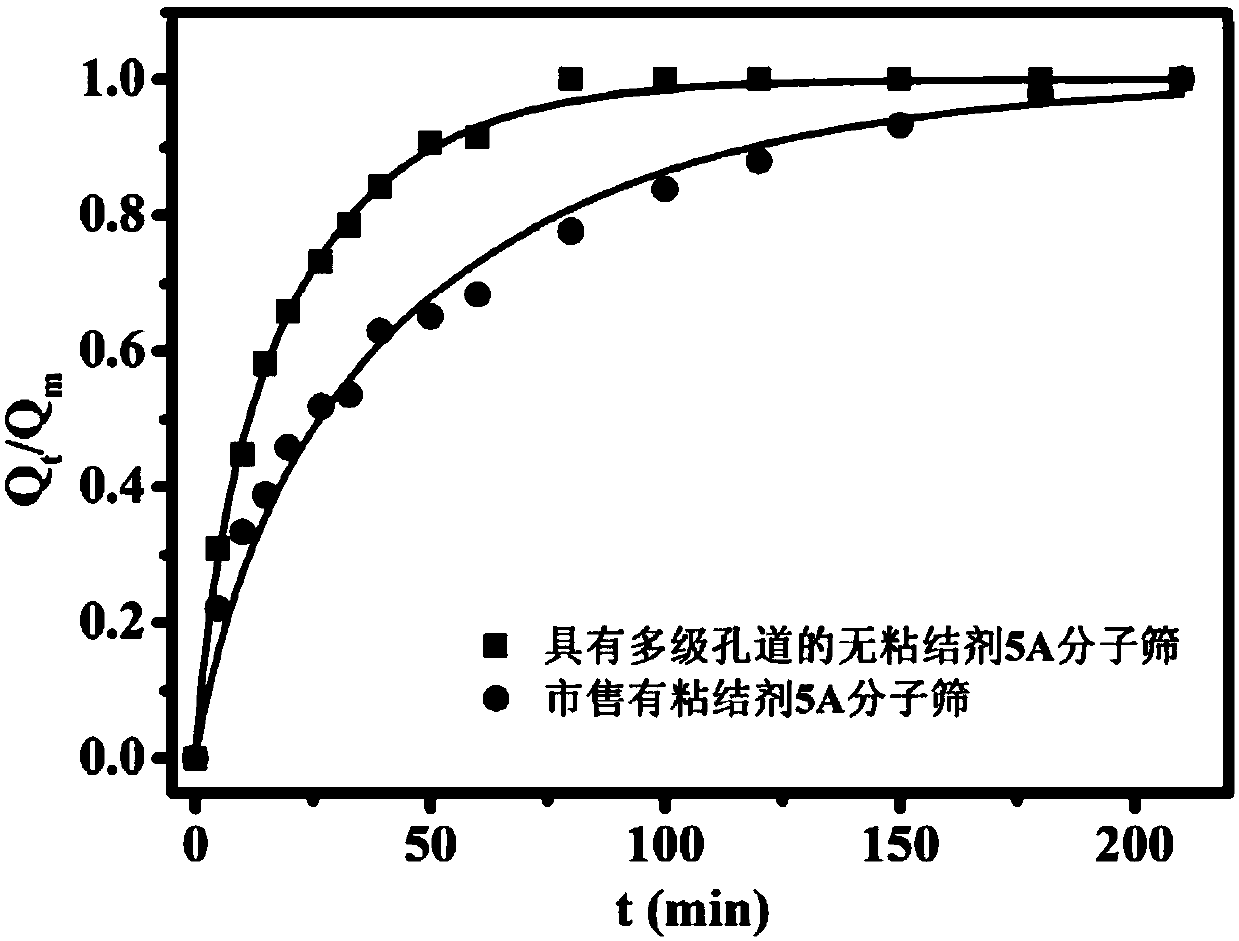

A binder-free and molecular sieve technology, applied in the direction of molecular sieves and alkali exchange compounds, chemical instruments and methods, A-type crystalline aluminum silicate zeolite, etc. Binder type A molecular sieve and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

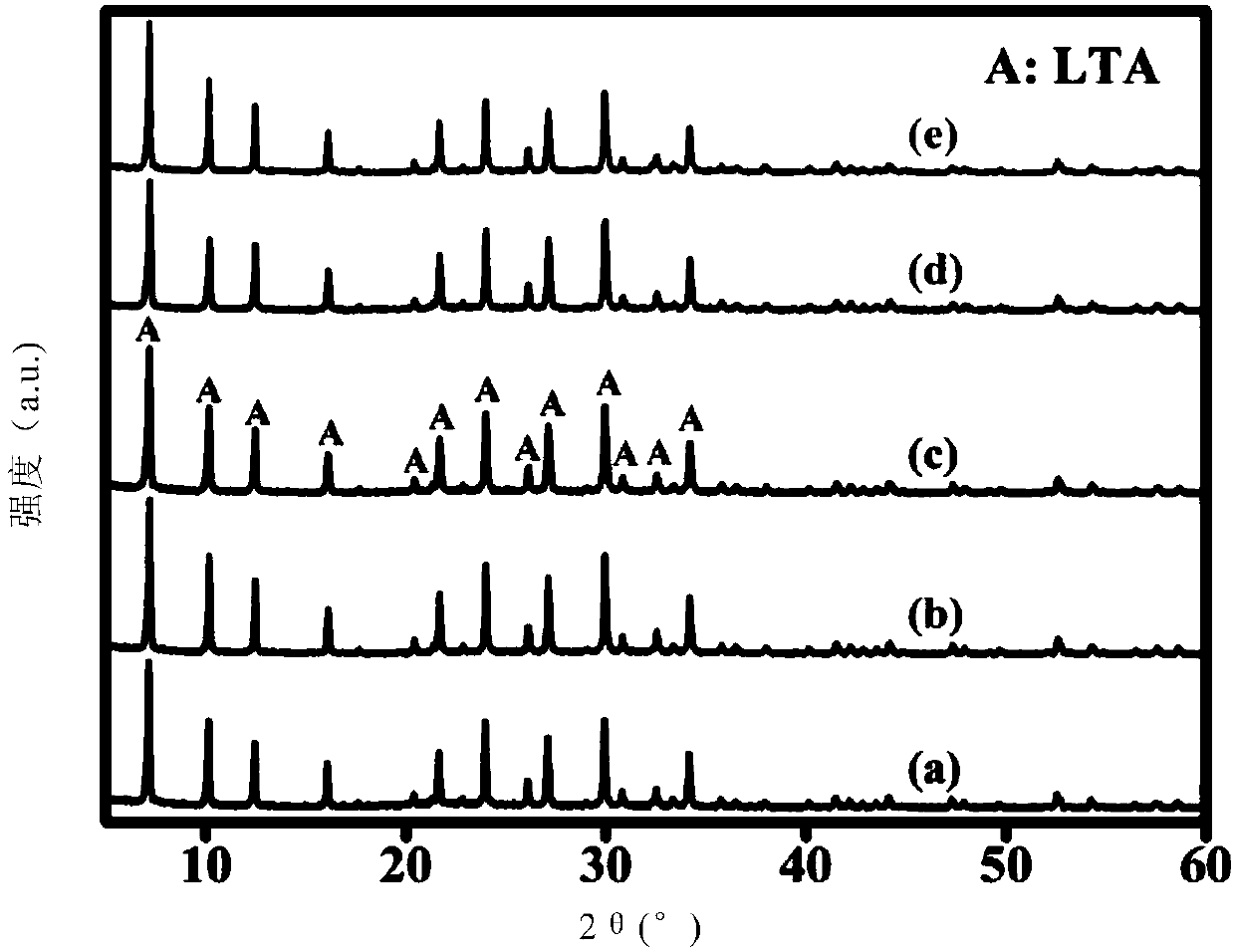

[0109] Preparation method of binder-free type A molecular sieve

[0110] The preparation method of the present invention may comprise the following steps:

[0111] (1) adding an aqueous surfactant solution and an oil phase to the water phase; wherein, the water phase is an alkali solution containing an aluminum source, thereby forming a system containing an oil phase, a surfactant phase and a water phase;

[0112] (2) Add the silicon solution containing gelling agent and optional hierarchical porous organic template to the described system containing oil phase, surfactant phase and water phase, after removing oil phase and surfactant phase, The water phase is crystallized to form a binder-free type A molecular sieve.

[0113] The temperature of the crystallization treatment may be 50-150°C (preferably, 50-100°C, more preferably, 60-80°C).

[0114] The time for the crystallization treatment may be 0.5-60 hours (preferably, 2-48 hours, more preferably, 4-12 hours).

[0115] A...

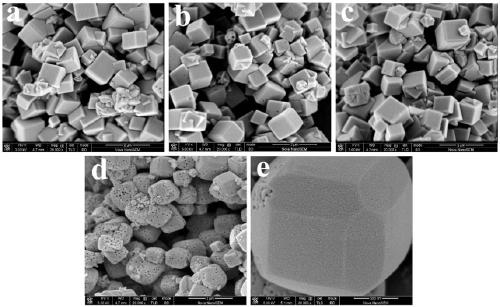

Embodiment 1

[0136] Preparation of oil / water two-phase system: Weigh 49.2 parts of sodium metaaluminate, 12.0 parts of sodium hydroxide and 216.0 parts of deionized water and stir to dissolve at room temperature, then slowly add 15 parts of cetyl trimethyl bromide in sequence ammonium chloride saturated aqueous solution and 30 parts of n-heptane to obtain an oil / water two-phase system with a surfactant phase between the two phases.

[0137] Synthesis of type A molecular sieve: Weigh 9 parts of ammonium chloride solution with a mass fraction of 10%, add it to 45 parts of a mass fraction of 40% silica sol (the diameter of the nanoparticle is 50nm), and disperse with droplets after uniform mixing into the oil / water two-phase. After separating and recovering the upper oil phase and the surfactant phase, the water phase was crystallized at 60° C. for 24 h. After the crystallization is completed, cool, filter, wash, and dry at 90° C. for 12 hours to obtain spherical A-type molecular sieve parti...

Embodiment 2

[0139] Preparation of oil / water two-phase system: Weigh 32.8 parts of sodium metaaluminate, 16.0 parts of sodium hydroxide and 216.0 parts of deionized water and stir to dissolve at room temperature, then slowly add 15 parts of hexadecyl trimethyl bromide in sequence ammonium chloride saturated aqueous solution and 30 parts of n-heptane to obtain an oil / water two-phase system with a surfactant phase between the two phases.

[0140] Synthesis of type A molecular sieve: Weigh 9 parts of ammonium chloride solution with a mass fraction of 10%, add it to 45 parts of a mass fraction of 40% silica sol (the diameter of the nanoparticle is 50nm), and disperse with droplets after uniform mixing into the oil / water two-phase. After separating and recovering the upper oil phase and the surfactant phase, the water phase was crystallized at 80° C. for 12 h. After the crystallization is completed, cool, filter, wash, and dry at 90° C. for 12 hours to obtain spherical A-type molecular sieve p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com