Laminated glass for vehicle

A technology for laminated glass and vehicles, which is applied in windshields, vehicle parts, glass/slag layered products, etc., can solve the problems of using lidar or near-infrared cameras, and the inability of laminated glass to work together, so as to improve the accuracy of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

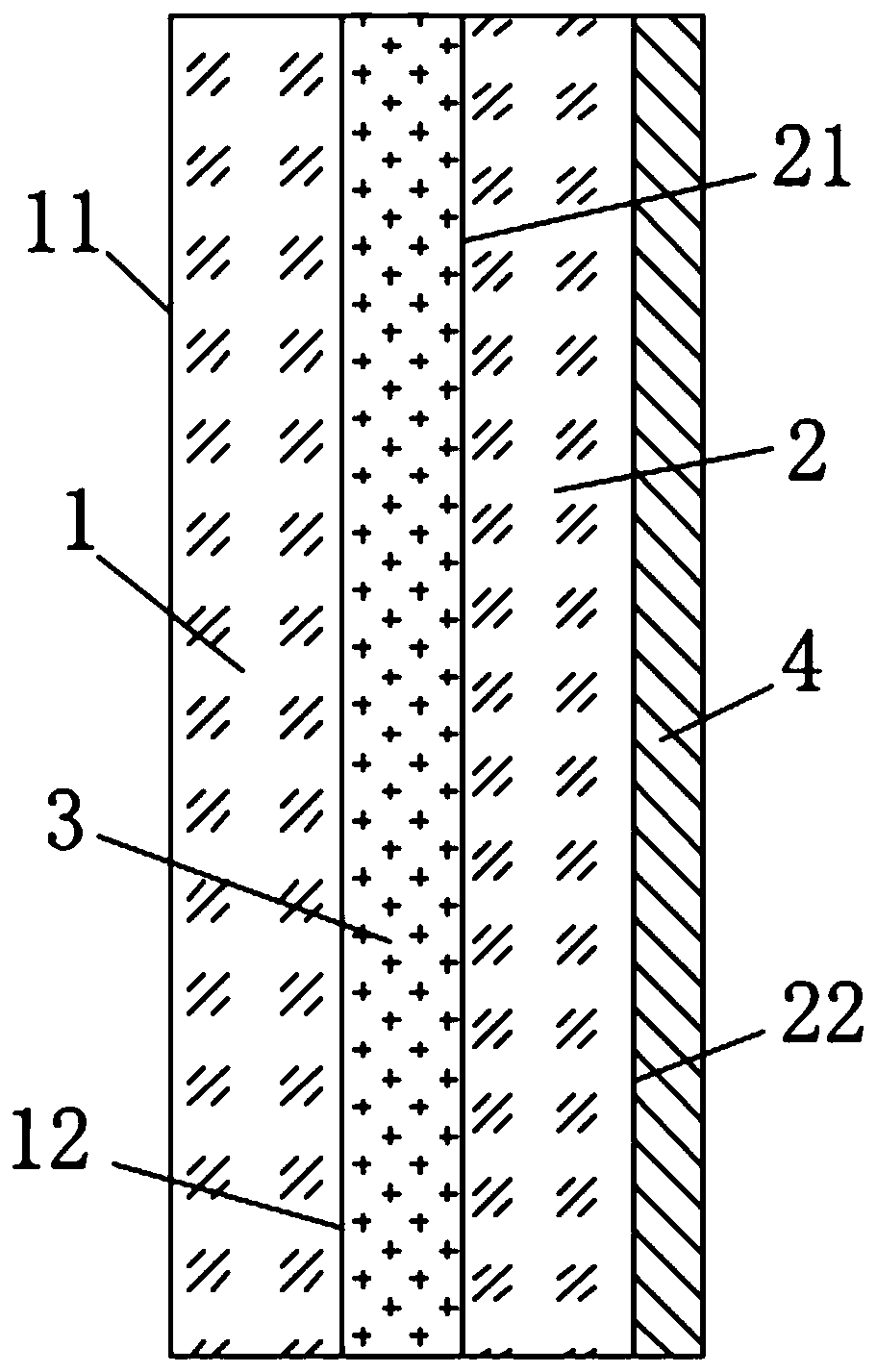

Image

Examples

Embodiment

[0037] In order to illustrate in more detail and support the invention points of the present invention more convincingly, some embodiments are listed for detailed elaboration. The laminated glass made in the following implementation cases is analyzed by the following schemes:

[0038] Transmittance: Analyze the transmission spectrum of the laminated glass with Agilent spectrophotometer equipment, and take the transmittance (T@905nm) corresponding to the wavelength of 905nm as the evaluation index.

Embodiment 1

[0041] Embodiment 1: take the soda calcium silicate float glass with a thickness of 1.6mm as the substrate, the white glass substrate has a transmittance of 85.94% and an absorptivity of 7.14% in the 900-1000nm wavelength range, the substrate After cutting, edging, washing and drying, etc., the coating deposition is carried out. The nano anti-reflection coating in Table 1 is deposited on the white glass substrate. Another white glass substrate and the white glass with nano anti-reflection coating deposited The substrates are assembled, shaped according to the high-temperature molding process of automobile glass, and a PVB film with a thickness of 0.76 mm is sandwiched in the middle, and the laminated glass of Example 1 is made through the initial pressure and high-pressure process of the combined sheet and the installation of accessories in other processes .

[0042] Table 1: Laminated glass structure and transmittance of Example 1 and Comparative Example 1

[0043]

[004...

Embodiment 2~5

[0047] Embodiment 2~5: take the soda lime silicate float glass with thickness 1.8mm and the ultra clear glass of 1.1mm as substrate, the white glass substrate of 1.8mm has 85.27% in the 900~1000nm wavelength range Transmittance and 7.77% absorptivity, 1.1mm ultra-white glass has 91.24% transmittance and 1.19% absorptivity in the wavelength range of 900-1000nm, after the substrate has been cut, edged, washed and dried Carry out coating deposition, deposit the nano anti-reflection film as shown in Table 2 on the 1.1mm ultra-clear glass, after the deposition is completed, match the 1.1mm ultra-clear glass with the 1.8mm white glass substrate, according to the high temperature of automobile glass The molding process is formed, and a PVB diaphragm with a thickness of 0.76 mm is sandwiched in the middle, and the laminated glass of Examples 2-5 is made through the initial pressure and high-pressure process of the combined sheet and the installation of accessories in other processes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com