A peelable blue rubber plug hole fixture and peelable blue rubber plug hole method

A technology of blue glue and plugged holes, which is applied to printed circuits, electrical components, printed circuits, etc., can solve problems such as low efficiency, high cost, and cumbersome processing procedures, and achieve smooth surfaces, stable airflow, and prevention of pits and holes The effect of edge overflow glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

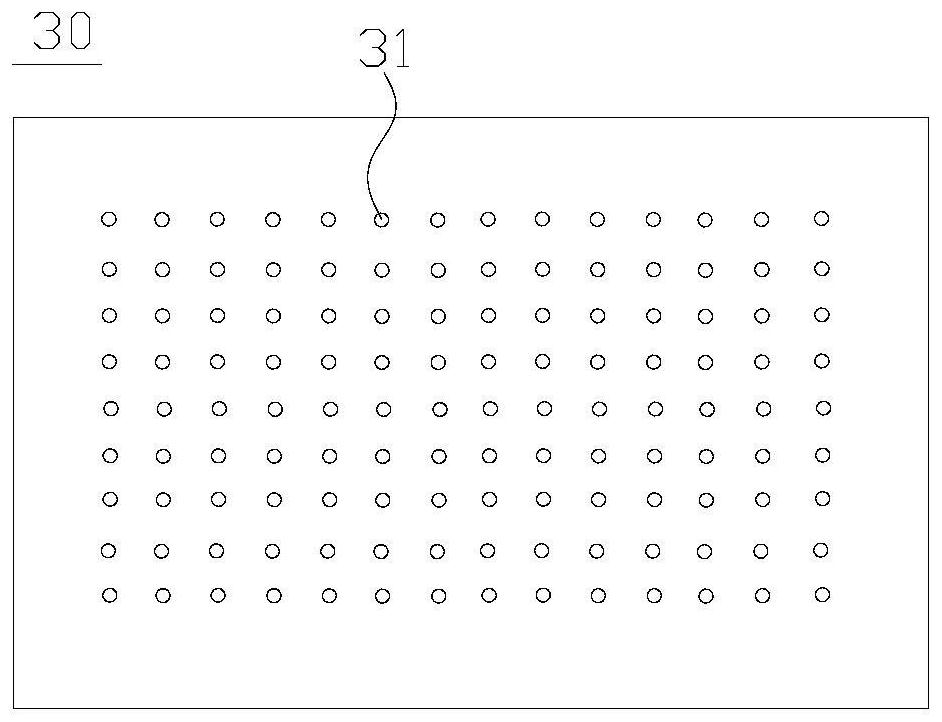

[0033] Such as Figure 1-6 As shown, this embodiment provides a peelable blue glue plug hole jig, which includes an air guide plate 10 , an air guide mesh backing plate 20 and a compressed air box 30 stacked in sequence from top to bottom.

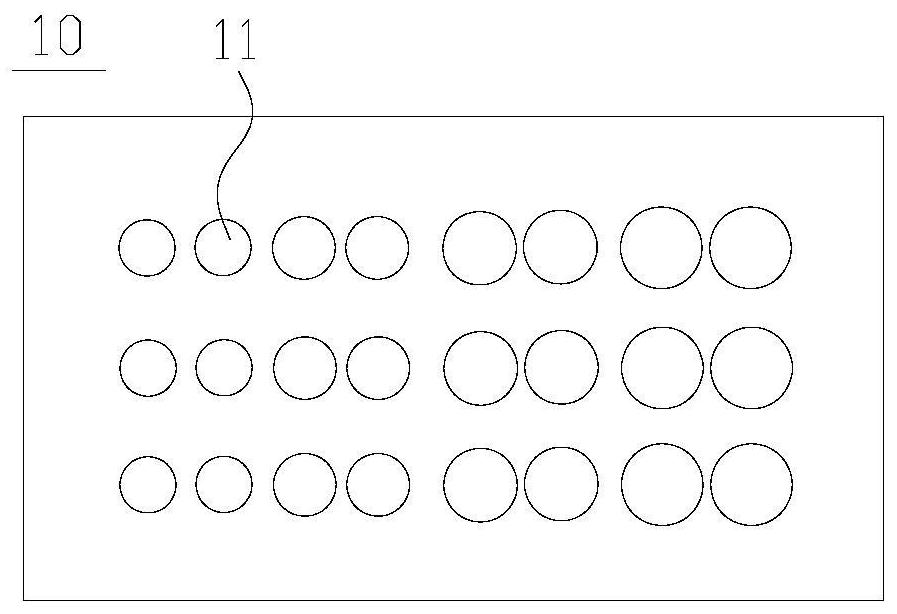

[0034] The air guide plate 10 is provided with air guide through holes 11, and the arrangement of the air guide through holes 11 corresponds to the through holes set on the PCB production board 50 to be processed, and the air guide through holes 11 on the air guide plate 10 The diameter of the hole is 2.0 mm larger than the diameter of the corresponding through hole on the PCB production board 50 .

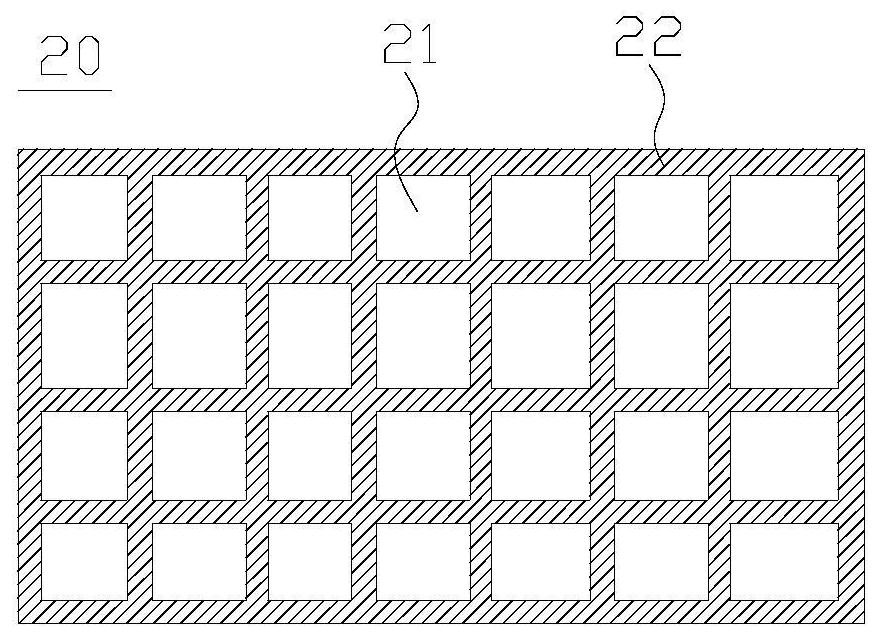

[0035] The air guide mesh backing plate 20 is provided with perforations 21 arranged in a matrix, and the perforations 21 are square perforations with a side length of 50 mm. The line width of the mesh wire 22 forming the square perforation 21 on the air guide mesh backing plate 20 is 3.0 mm. The thickness of the air guide mesh backing plate...

Embodiment 2

[0044]This embodiment provides a peelable blue glue plug hole jig, including air guide plates and compressed air boxes stacked up and down. The structures of the air guide plate and the compressed air box in this embodiment are the same as those of the air guide plate and the compressed air box described in Embodiment 1. Compared with Example 1, the peelable blue glue plug hole jig of this example has no air guide mesh backing plate.

[0045] When using a screen printing machine to screen-print the peelable blue glue on the PCB production board, use the peelable blue glue plug hole jig of this embodiment to assist the silk screen printing, including steps S1-S4.

[0046] Step S1 is as follows: S1. Fix the strippable blue rubber plug hole fixture on the working table of the screen printing machine, that is, stack the compressed air box and the air guide plate on the working table of the screen printing machine in sequence, and use ordinary tape to seal the compressed air box. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com