High-frequency polishing quartz wafer with long H-shaped structure

A quartz wafer and wafer technology, applied in the field of communication, can solve the problems of chip damage, the overlapping area cannot be cleaned, the crystal resonator DLD2 parameter is large, etc., and the effect of preventing the cleaning from being unclean is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

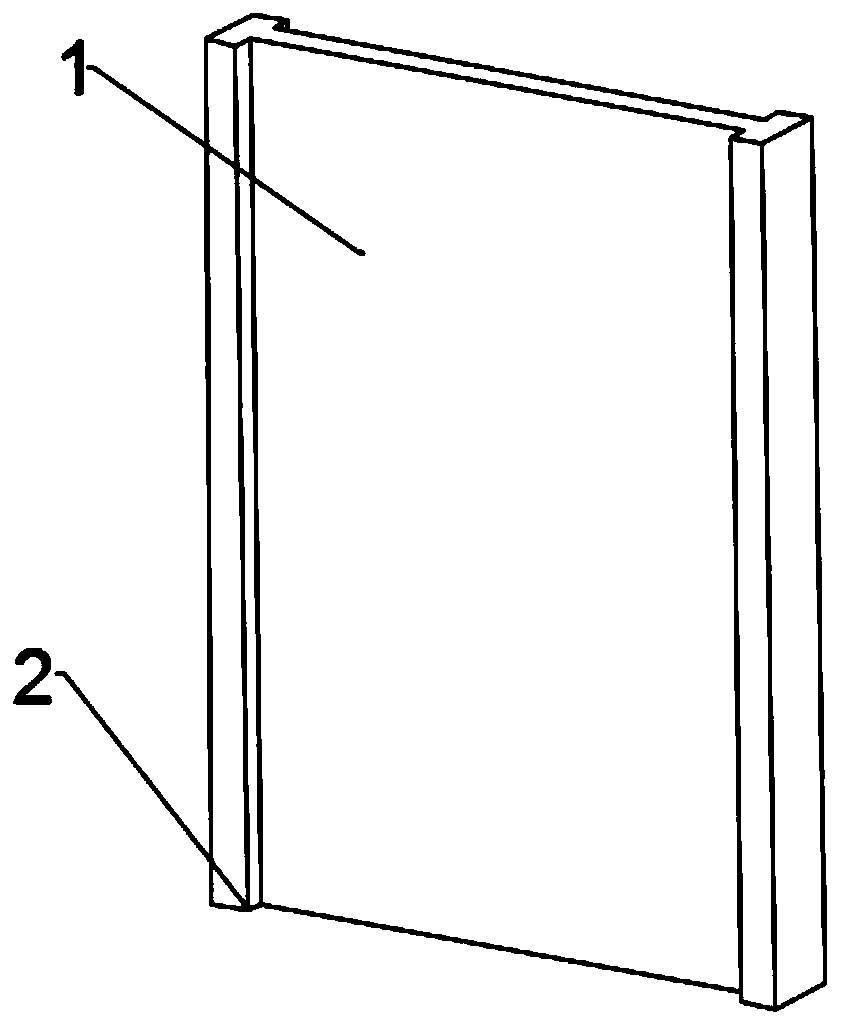

[0036] A high-frequency polished quartz wafer with a long H-shaped structure provided by a preferred embodiment of the present invention, the web wafer 1 is set as the original wafer in the present invention, when the length, width and height of the web wafer 1 are respectively 1.35mm, 0.93mm and 0.017 mm, the ANSYS finite element software is used to calculate the amplitude-frequency characteristics and impedance characteristics of the crystal vibration of the original wafer under the excitation of the alternating electric field through harmonic response analysis; the impedance value is 40Ω.

Embodiment 2

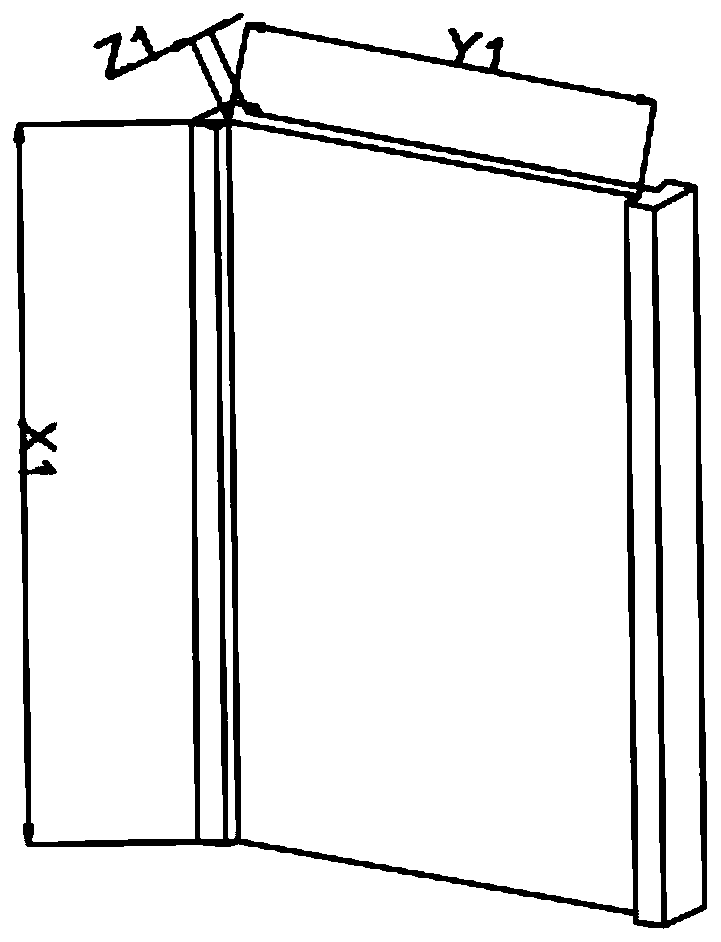

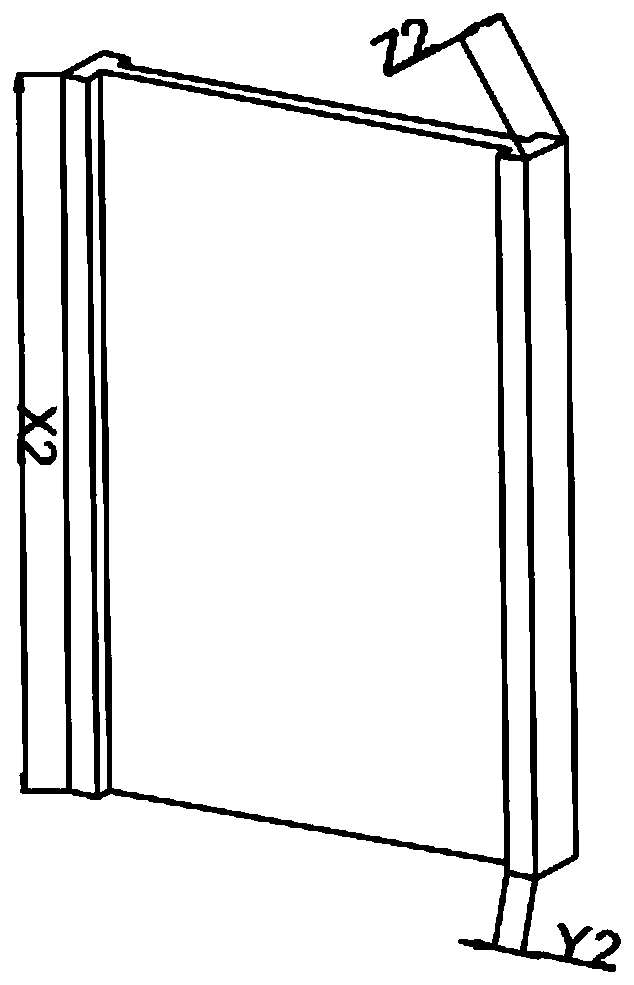

[0038] In this embodiment, on the basis of Embodiment 1, the length of the flange plate wafer 2 is 1.35mm, and the width and height are variables; the length, width and height of the web wafer 1 are 1.35mm, 0.93mm and 0.017mm respectively; Calculate the amplitude-frequency characteristics and impedance characteristics of the crystal vibration under the excitation of the alternating electric field for the long H-shaped quartz wafer; obtain the impedance value, as shown in Table 1.

[0039] Table 1

[0040]

[0041] As can be seen from Table 1, the size of the long H-shaped quartz wafer is as shown above. Compared with the impedance value of the original wafer, it can be found that as the size of the flange plate Y2 increases, it means that the length / width of the overall structural size of the long H-shaped quartz wafer Ratio decreases, crystal vibration is suppressed, so its impedance will increase; on the contrary, as the size of the flange plate Z2 increases, the terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com