Battery pack heat dissipation structure and device

A technology of heat dissipation structure and battery pack, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as temperature rise, and achieve the effect of solving excessive temperature rise and improving heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

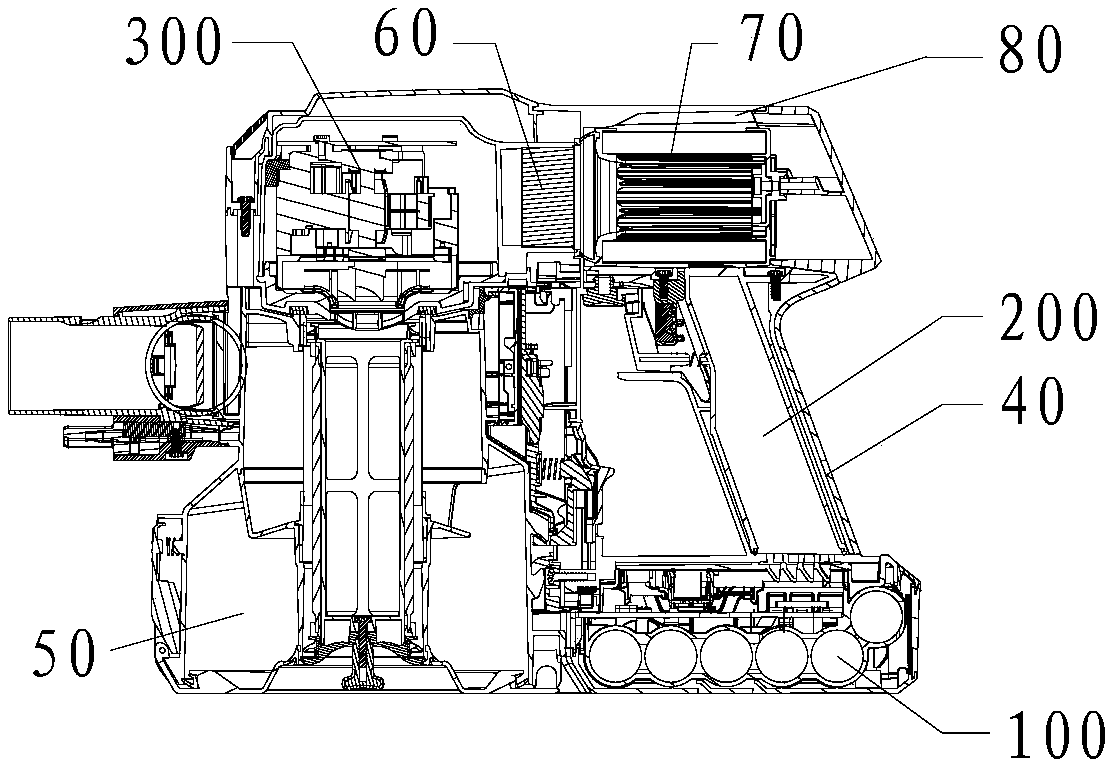

[0030] image 3 It is a sectional view of Embodiment 1 of the present invention. Such as image 3 As shown, in this embodiment, the device is a vacuum cleaner, the battery pack 100 is arranged under the handle 40 of the vacuum cleaner, the fan 300 is a motor for providing suction in the vacuum cleaner, and the ventilation duct 200 is a hollow vacuum cleaner. A part of the vents 110 communicates with the handle 40 , and the other part directly communicates with the air outside the battery pack 100 .

[0031] When the vacuum cleaner is working, the dust-laden air enters the dust storage chamber 50 of the vacuum cleaner from the suction port of the vacuum cleaner under the suction provided by the motor. After being processed by the separator, most of the dust remains in the dust storage chamber 50, and the air passes The motor then blows to the inside of the battery pack through the ventilation duct 200 to take out the heat in the battery pack, thereby reducing the temperature ...

Embodiment 2

[0035] Figure 4 It is a sectional view of Embodiment 2 of the present invention; Figure 5 for Figure 4 Partial enlarged view of A. Such as Figure 4 and Figure 5 As shown, similar to Embodiment 1, the device described in this embodiment is a vacuum cleaner, the battery pack 100 is arranged under the handle 40 of the vacuum cleaner, and the fan 300 is a motor for providing suction in the vacuum cleaner, which is different from Embodiment 1 Notably, in this embodiment, the ventilation duct 200 is a hollow shell between the dust storage chamber 50 of the vacuum cleaner and the battery pack 100 . Specifically, the dust storage chamber 50 is provided with an air intake hole 501 at the position facing the battery pack 100, and correspondingly, a part of the vent 110 is provided on the side of the battery pack 100 facing the dust storage chamber 50, and the Part of the vent 110 communicates with the air inlet 501 on the dust storage chamber 50 through the hollow shell, that ...

Embodiment 3

[0039] Figure 6 It is a structural schematic diagram of Embodiment 3 of the present invention; Figure 7 It is a sectional view of Embodiment 3 of the present invention. Such as Figure 6 and Figure 7 As shown, in this embodiment, the device is an electric screwdriver, the battery pack 100 is arranged under the handle of the electric screwdriver, the fan 300 is a motor that rotates the screwdriver in the electric screwdriver, and the ventilation duct 200 is an electric screwdriver. The hollow shell between the screwdriver battery pack 100 and the motor, the plurality of vents 110 are partly communicated with the hollow shell, and partly communicated directly with the air outside the battery pack 100 .

[0040] When the electric screwdriver is working, the motor drives the screwdriver to rotate, and the air generated passes through the ventilation duct 200, enters the battery pack 100, and then flows to the outside air through the vent 110, thereby taking out the heat in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com