Rotary kiln shell with forward and reverse bidirectional rotation

A technology of two-way rotation and rotary cylinder, which is applied in the direction of rotary drum furnace, furnace, furnace type, etc., can solve the problems of delay in construction period, high cost and cost, stuck or slippery, etc., to enhance the connection strength and improve the service life , save maintenance trouble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

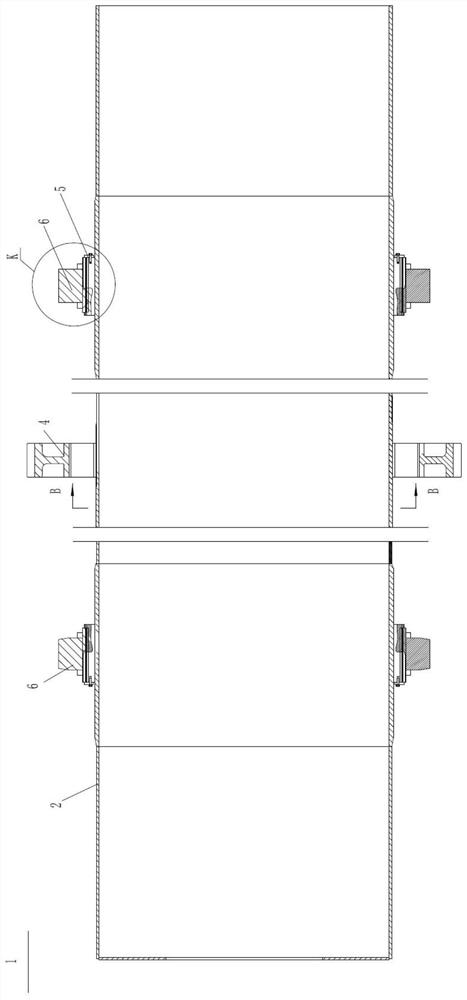

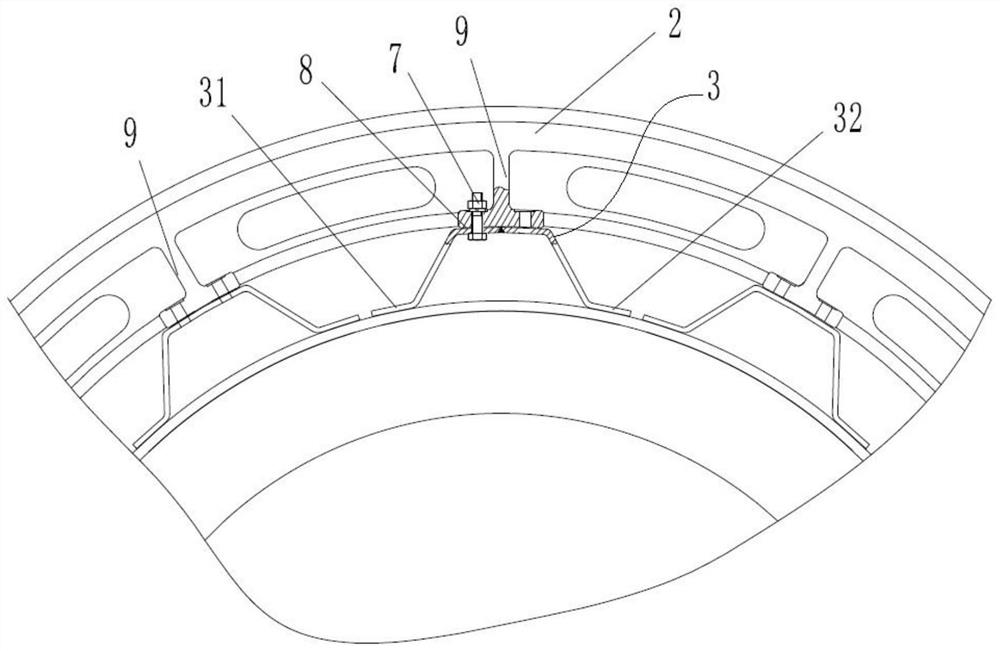

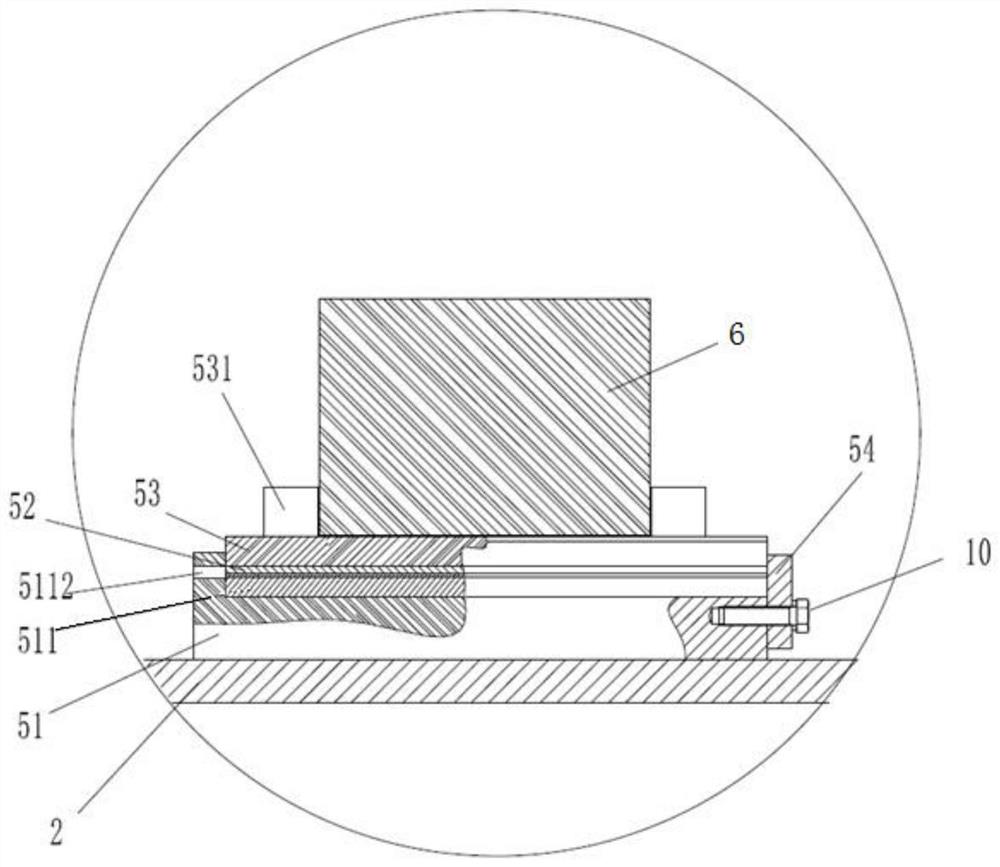

[0041] In an embodiment of the present invention, please refer to figure 1 , which shows a schematic structural diagram of a rotary kiln cylinder 1 rotating in both forward and reverse directions according to an embodiment of the present invention. The rotary kiln cylinder body 1 that rotates in both forward and reverse directions includes a rotary cylinder body 2, multiple sets of two-way fixed spring pull plates 3, a large gear 4, multiple height-adjustable support bases 5 and multiple tire belts 6, wherein:

[0042] The rotary cylinder body 2 has two rotation directions, and the two rotation directions include forward rotation and reverse rotation. In this embodiment, there is no special requirement for the selection of the structure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com