Split mechanical seal with split ring connection interface adopting magnetic fluid sealing for molten salt pump

A magnetic liquid, mechanical seal technology, applied in mechanical equipment, engine seals, engine components, etc., can solve the problems of leakage channels, fluid leakage, etc., to achieve the effect of convenient assembly and disassembly, low maintenance costs, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

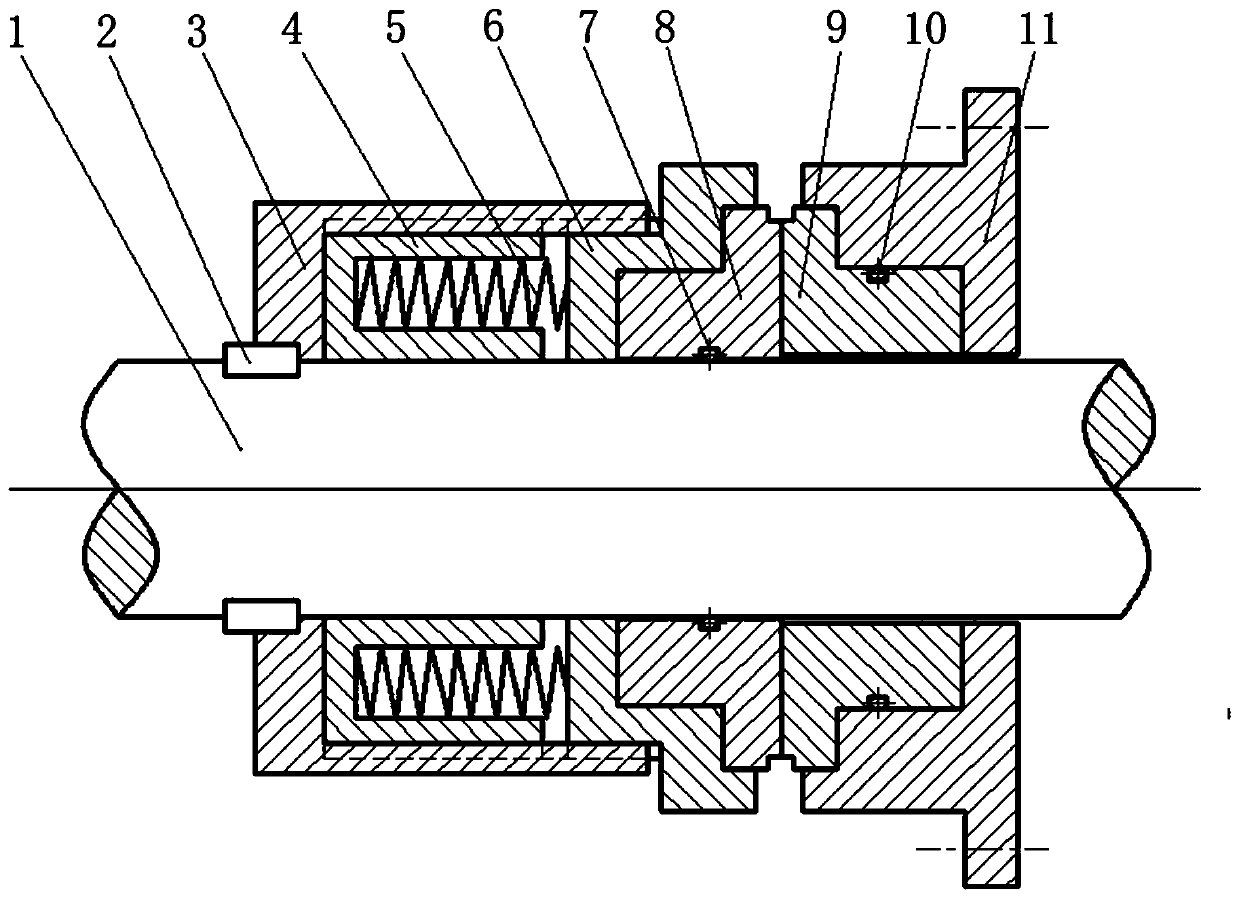

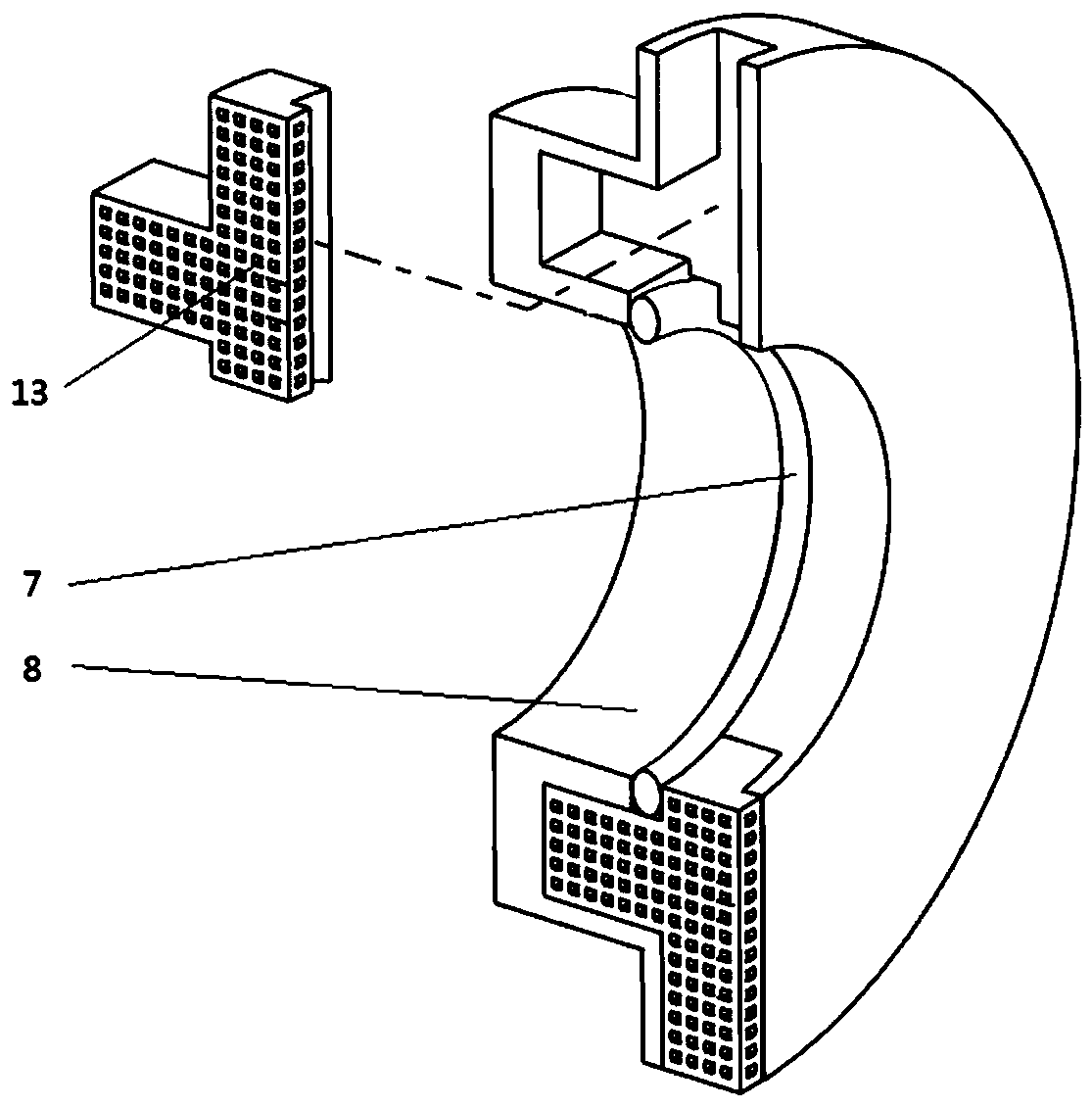

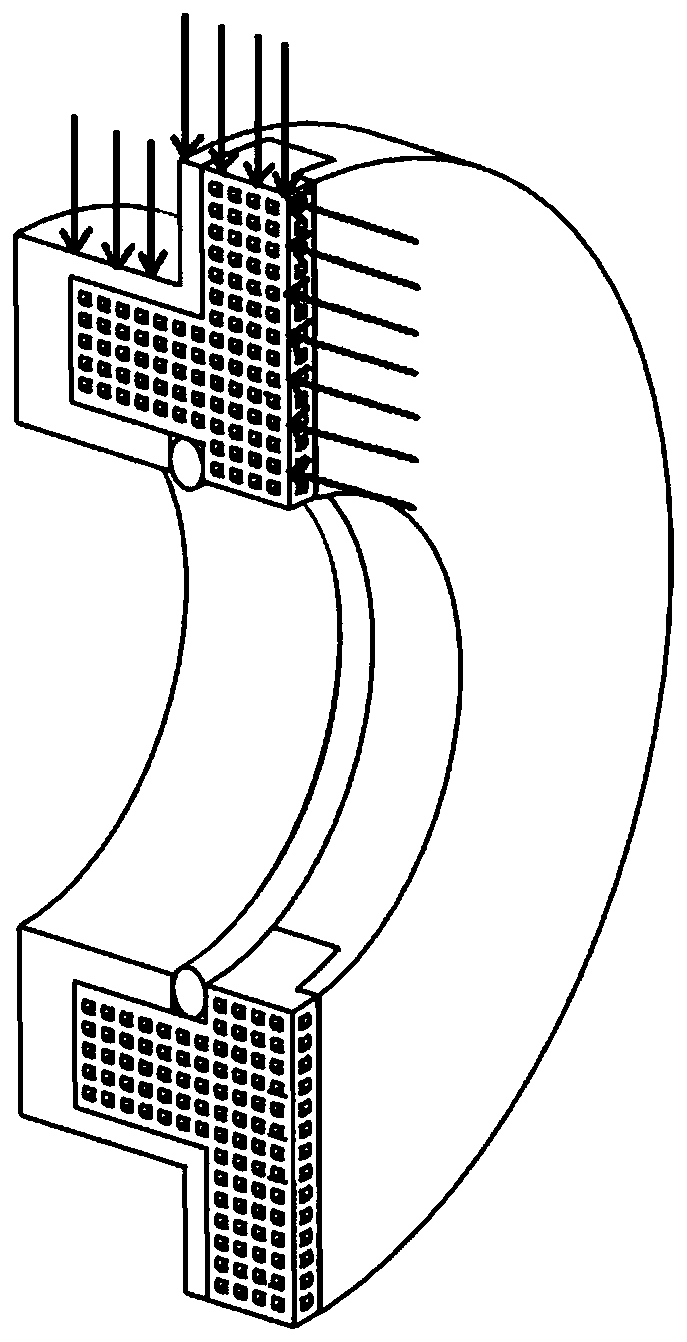

[0047] In order to describe the above-mentioned features and advantages of this patent more clearly, the specific implementation manners of this patent will be further described below in conjunction with the accompanying drawings.

[0048] Install the split ring mechanical seal for the molten salt pump with the magnetic liquid seal at the interface of the split ring on the rotating shaft 1, and the steps are as follows:

[0049] Step 1. First install the key 2 in the keyway of the shaft 1, then put the transmission sleeve 3 on the shaft 1, the keyway at the bottom of the transmission sleeve 3 matches the key 2, and then install the springs 5 equidistantly distributed around the circle. The seat 4 is installed inside the drive sleeve 3. At this time, the groove on the outside of the spring seat 4 should be in one-to-one correspondence with the semicircular boss 17 on the inner wall of the drive sleeve 3, and then the moving ring seat 6 should be installed inside the drive slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com