A wedge-type prefabricated shield segment waterproof structure

A shield segment and waterproof structure technology, which is applied in shaft equipment, wellbore lining, mining equipment, etc., can solve problems such as inability to ensure close fit, hidden dangers of waterproofing, etc., and achieve simple structure, easy operation, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific embodiments.

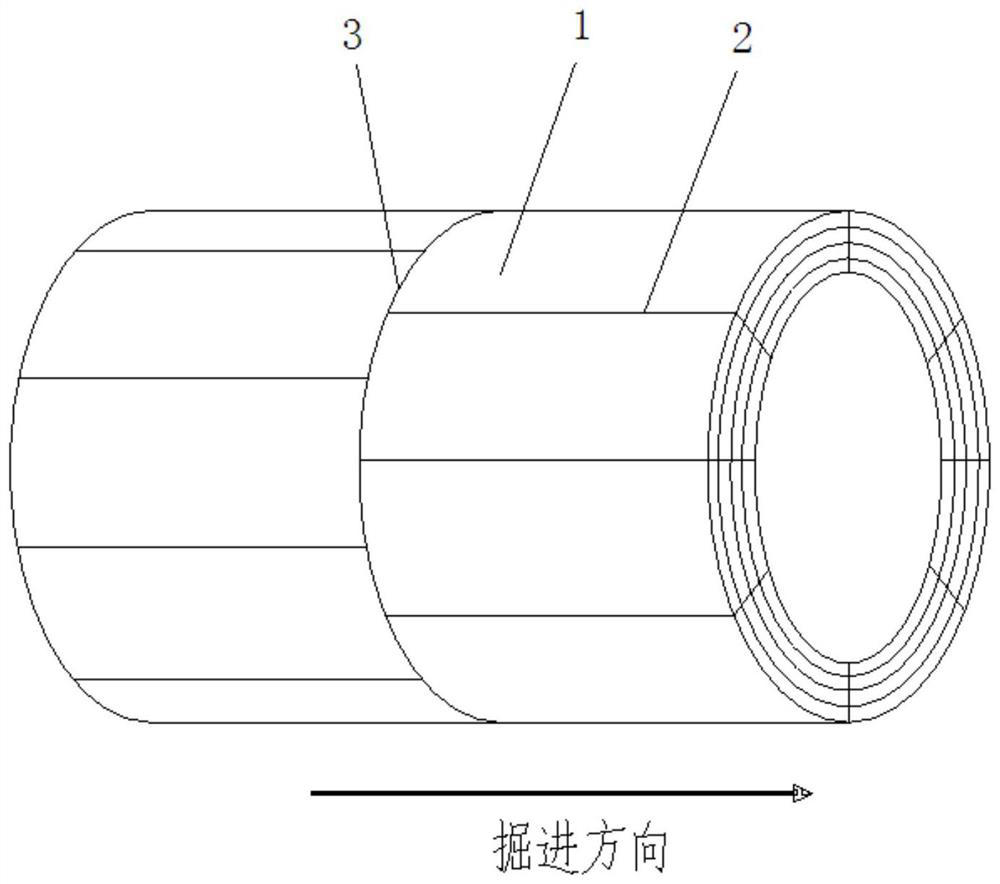

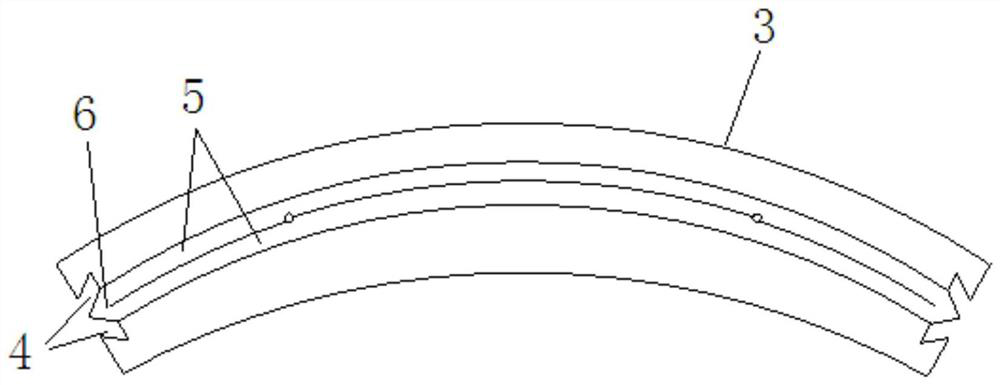

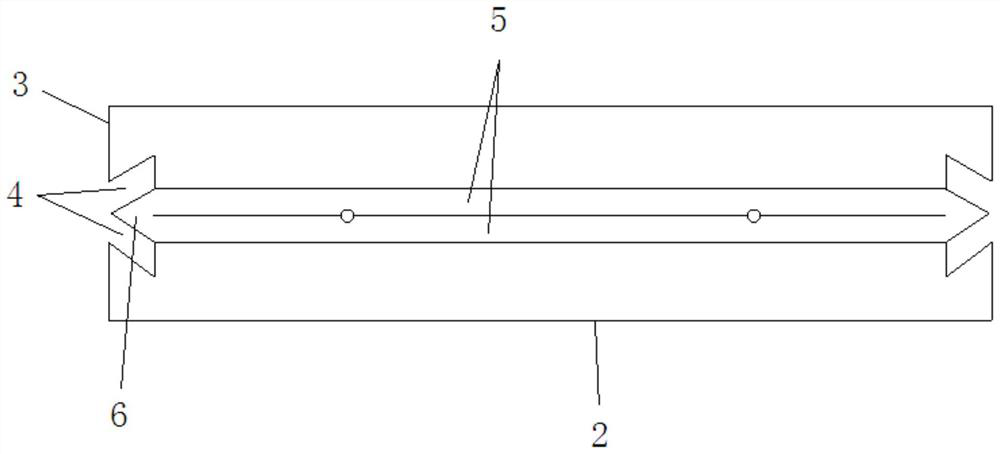

[0038] to combine figure 1 —8, a wedge-type prefabricated shield segment waterproof structure, including a prefabricated lining segment unit 1, the annular seam end 3 of the segment is provided with an annular seam groove 5, and the longitudinal seam end 2 of the segment is provided with a longitudinal seam The grooves 4, the axially adjacent annular grooves 5 and the longitudinally adjacent longitudinal grooves 4 are connected and assembled by annular sealing strips 12 and longitudinal sealing strips 9, respectively.

[0039] The cross sections of the annular seam groove 5 and the longitudinal seam groove 4 are both "V" shaped, and the interior of the annular seam groove 5 and the longitudinal seam groove 4 are equipped with a triangular wedge-shaped structure 6, and the point position of the triangular wedge-shaped structure is There is a distance of more than 1 mm from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com