Tunnel inverted arch and inverted arch filling layer replacing steel-concrete composite structure and construction technology

A technology of combined structure and filling layer, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of many construction procedures, subsidence, and uncompact concrete pouring of vaults.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

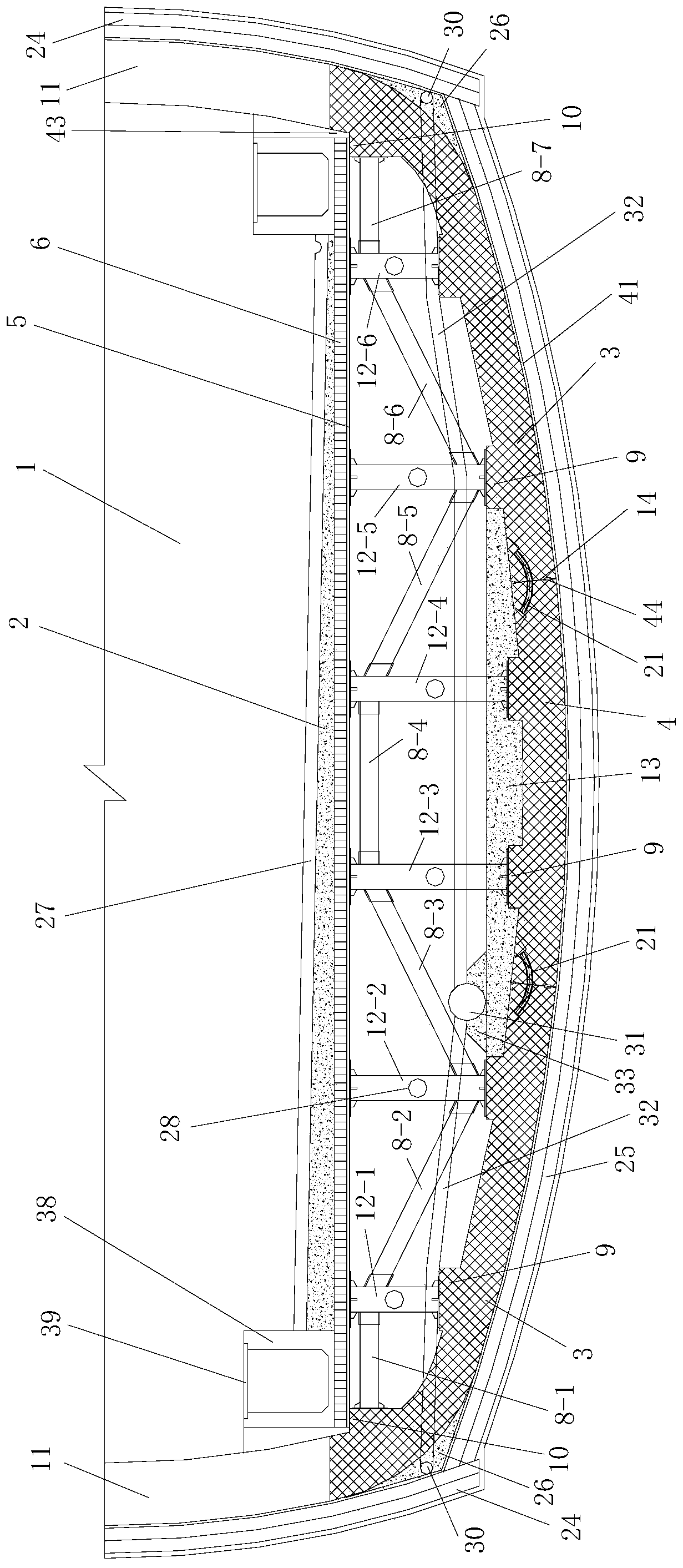

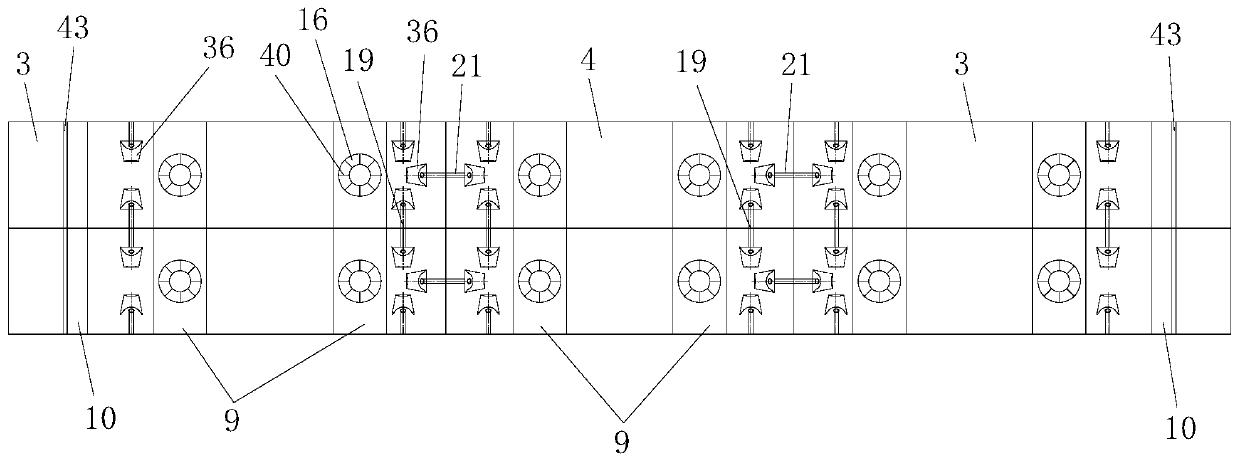

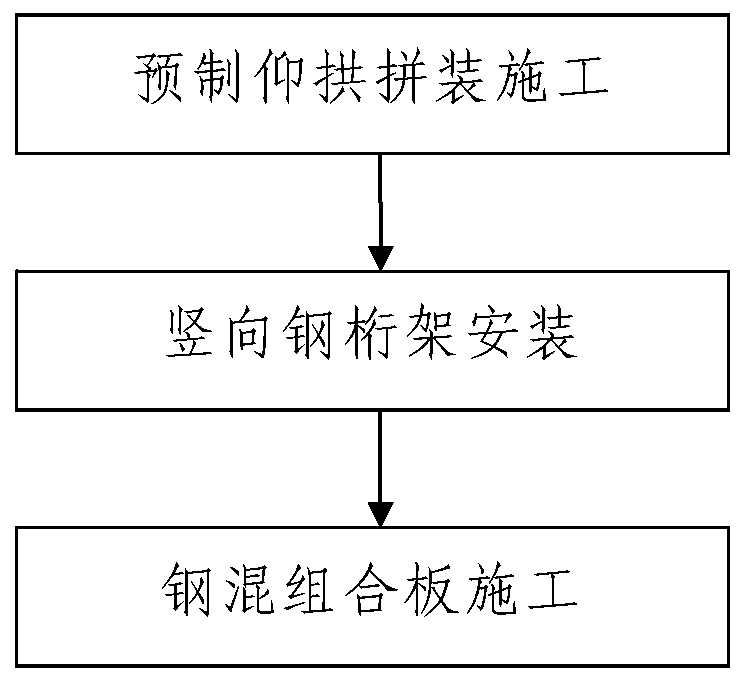

[0103] Such as figure 1 , figure 2 and Figure 13 As shown, the tunnel inverted arch and the inverted arch filling layer of the present invention replace the steel-concrete composite structure, and are composed of a prefabricated inverted arch arranged in the constructed tunnel 1 and a steel truss structure arranged on the prefabricated inverted arch; The prefabricated inverted arches are assembled from multiple assembled inverted arches, the structures and dimensions of which are the same, and they are arranged from back to front along the longitudinal extension direction of the tunnel 1 being constructed; the steel trusses The structure includes a plurality of vertical steel trusses arranged from back to front along the longitudinal extension direction of the constructed tunnel 1 and steel-concrete composite panels horizontally supported on the plurality of vertical steel trusses. The structure and size are the same; each said vertical steel truss is provided above the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com