Method for preventing impact ground pressure of hard roof remained roadway by buffer pressure relief belt and wide roadway flexible wall

A technology of rock burst and pressure relief belt, which is applied in ground mining, earth drilling, underground mining, etc., to achieve the effects of preventing rock burst, reducing engineering costs, and changing impact properties

Active Publication Date: 2019-09-10

SHANDONG UNIV OF SCI & TECH

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve the problem of rock burst in gob-side entry under the condition of hard roof at present, and propose a method for preventing and controlling rockburst in gob-side entry with buffer pressure relief belt and wide-opening flexible wall

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] Those skilled in the art according to the technical scheme described in the content of the invention and figure 1 , figure 2 The schematic diagram shown can be implemented and will not be described in detail here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

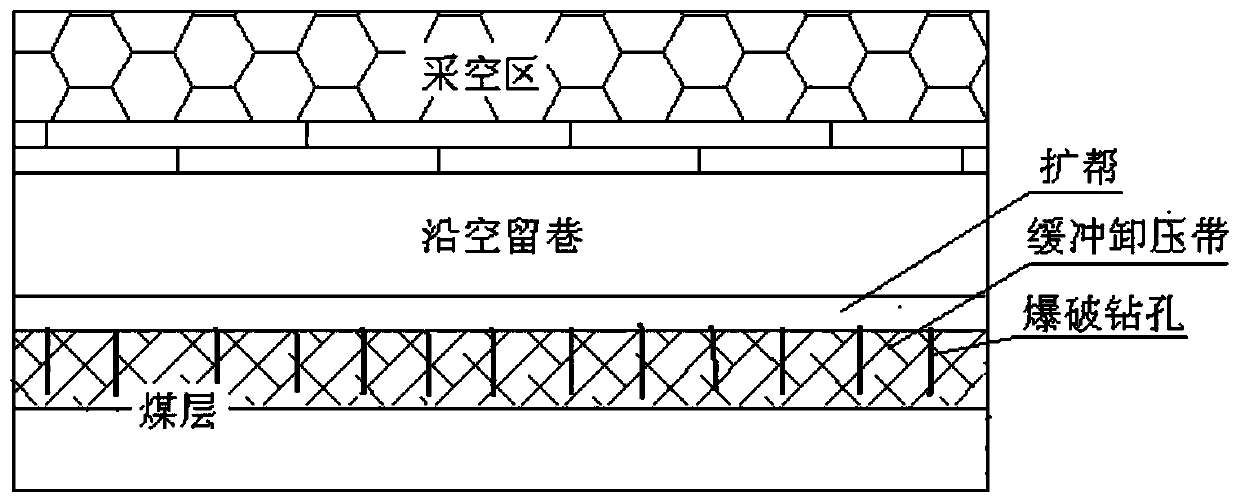

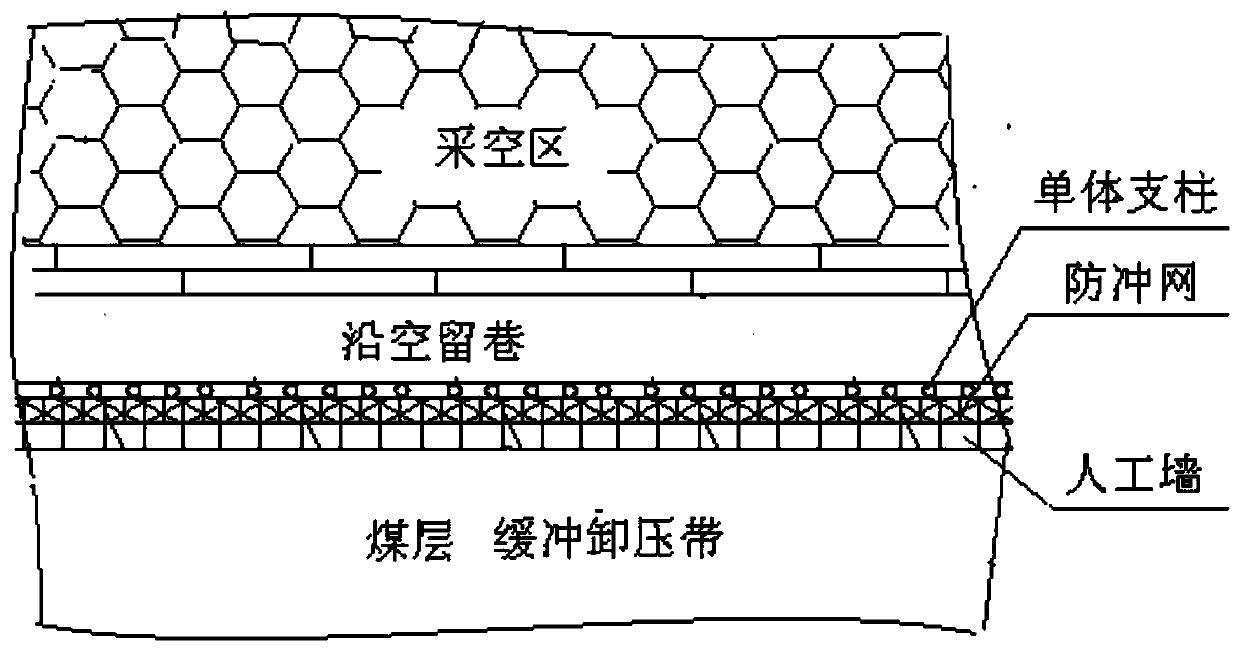

The invention discloses a method for preventing impact ground pressure of a hard roof remained roadway by a buffer pressure relief belt and a wide roadway flexible wall. The method is characterized bycomprising the steps that firstly, side expanding and bottom excavating are carried out on the coal wall side of an original remained roadway, and coal bodies after side expanding is carried out areloaded into a woven bag for stand-by application; in accordance with a conventional method, holes are punched in the coal wall after side expanding is carried out for blasting, and the buffer pressurerelief belt with the width of 8-12 m is artificially manufactured; the woven bag with loaded materials is used as the wall material, and an artificial wall with the width of 1.5-1.6 m is built alongthe space position after side expanding is carried out; and the flexible wall is reinforced and blocked by a combined technique of a protective net and a single prop. Through the buffer pressure relief, the impact properties of the coal bodies are changed; and the artificial flexible wall and blasting in the roadway side are adopted to form a flexible body so as to realize impact prevention of theremained roadway.

Description

technical field [0001] The invention belongs to the technical field of coal mining. Background technique [0002] Gobside entry retention (referred to as entry entry retention) means that after the mining of the previous section of the coal mine, the transport entryway is expanded and maintained with special support materials, so that it is retained as a return to the next section of the working face. Wind Lane. This kind of roadway can be used twice, which is a method in the coal pillarless mining technology. Gobside retaining can maximize the recovery of resources and avoid coal loss. [0003] Rockburst is one of the most serious dynamic disasters. The geological factors affecting rockburst include structure, buried depth, roof, coal seam hardness, mining factors, etc.; the deeper the geological factors play the decisive role, and the damage appears to be more serious , in which the rockburst caused by the hard roof occupies a large proportion and is more destructive. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21C41/18E21F17/107F42D3/00

CPCE21C41/18E21F17/107F42D3/00

Inventor 潘立友唐鹏孙久政陈理强

Owner SHANDONG UNIV OF SCI & TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com