Molten iron desulphurization stirring spray gun

The technology of molten iron desulfurization and spray gun is applied in the field of molten iron desulfurization stirring spray gun, which can solve the problems of poor mixing effect of desulfurization agent and molten iron, low desulfurization efficiency, high spray intensity of desulfurization agent, etc., so as to improve the utilization rate, desulfurization efficiency and low cost. , the effect of reducing the fracture phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

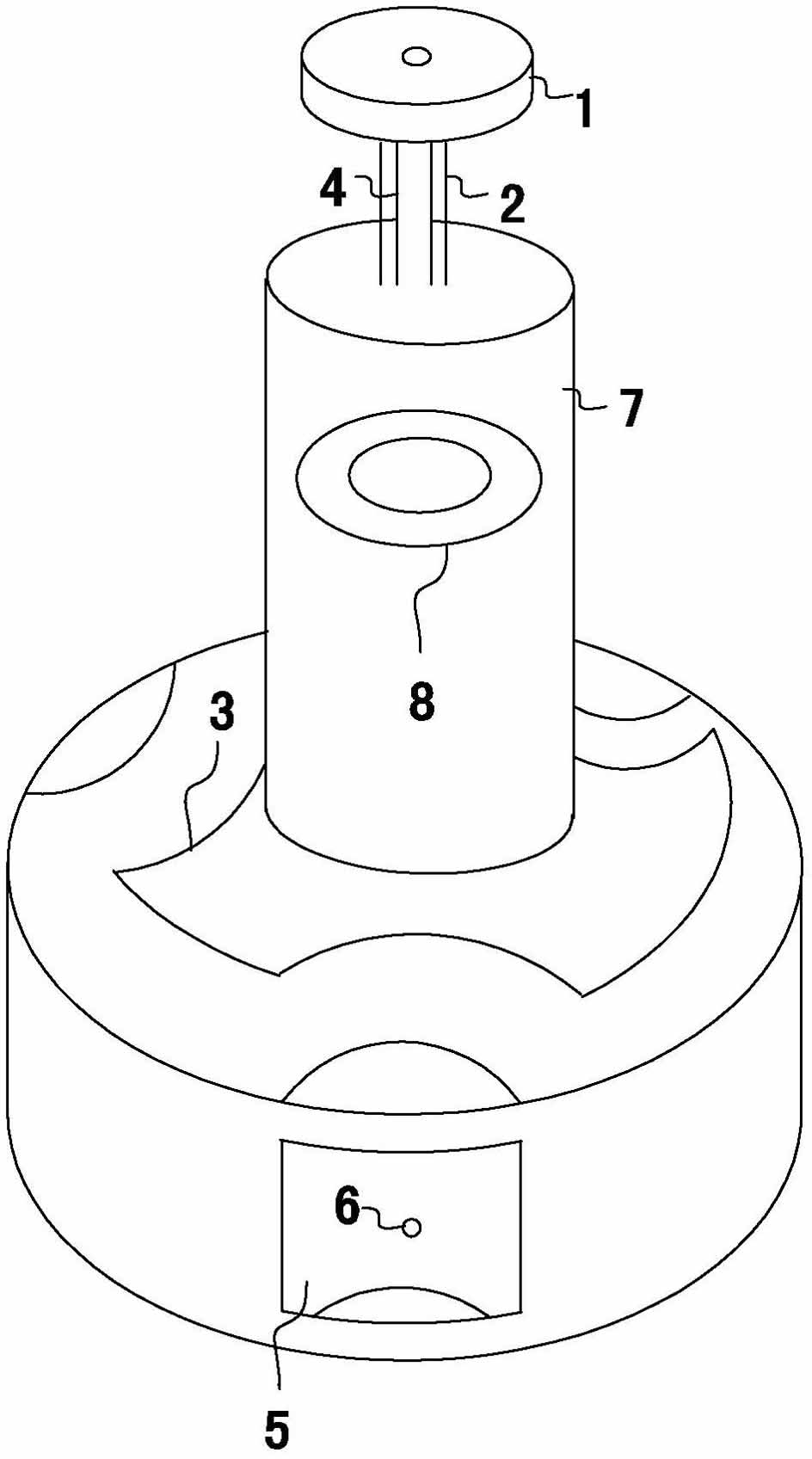

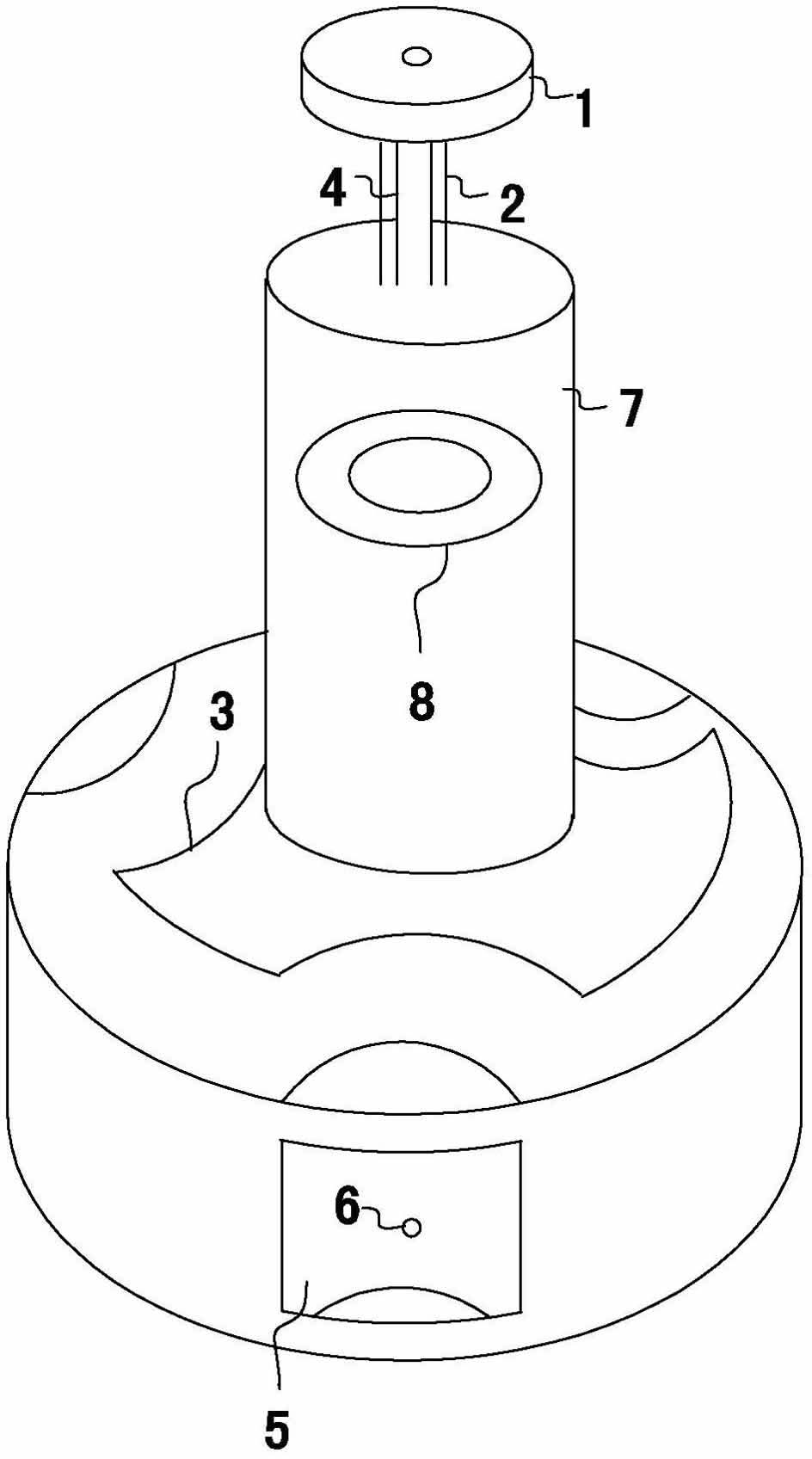

[0015] As shown in the figure, the iron water desulfurization mixing spray gun includes the flange connector 1. The mixing shaft 2 fixed with the flange connector 1 and the stirring blade 3 with the lower part of the mixing shaft 2;3 and the mixing shaft 2 are attached to the refractory material layer 7; there is a nozzle 4 in the fixed set of the mixing shaft 2;There is a nozzle 6 in the Gadian Vaporization Room 5;

[0016] The semi -cylindrical vaporization room 5 is three in the present invention.

[0017] The stirring blade 3 described in the present invention is a disc.

[0018] In order to improve the stress distribution in the gun and avoid cracking and falling off the refractory material, the refractory material layer 7 can be provided with a ring stress adjustment reinforcement 8 within 7.

[0019] When the present invention is used, the desulfurizing agent spraying system spray desulfurization from no spray 4, spray port 6, and semicircular pillar vaporization room 5 int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com