Lead-based alloy for cable sheath and production technology thereof

A lead-based alloy and production process technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of unstable composition and performance, unstable processing load, loss of manufacturers, etc., to improve moisture-proof and waterproof performance, and improve consistency and compactness, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

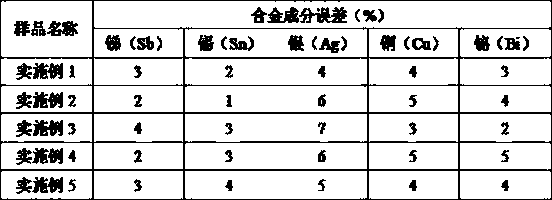

Embodiment 1

[0012] A lead-based alloy for cable sheath, which is prepared by melting the following components by weight percentage: antimony 0.2%, tin 0.4%, silver 0.025%, copper 0.02%, bismuth 0.04%, and the rest are lead, and lead in lead is 0.04%. Net content ≥99.994%, net content of antimony in antimony ≥99.0%, net content of tin in tin ≥99.9%, net content of bismuth in bismuth ≥99.997%, net content of silver in silver ≥99.99%, net content of copper in copper Content ≥ 99.95%.

[0013] The production process of the above-mentioned lead-based alloy for cable sheathing, the specific operation steps are as follows: adding a formula amount of lead into a lead smelting furnace, heating to 400-450 ° C, the lead is completely melted, adding an appropriate amount of slag remover, Turn on the mixer to stir, let the slag remover and lead slag fully react to powder, use special tooling to salvage the lead slag floating on the surface of the lead liquid, raise the temperature to 400-450 ℃, add th...

Embodiment 2

[0015] A lead-based alloy for cable sheath, which is prepared by melting the following components by weight percentage: antimony 0.1%, tin 0.45%, silver 0.02%, copper 0.03%, bismuth 0.05%, and the rest are lead, and lead in lead is 0.05%. Net content ≥99.994%, net content of antimony in antimony ≥99.0%, net content of tin in tin ≥99.9%, net content of bismuth in bismuth ≥99.997%, net content of silver in silver ≥99.99%, net content of copper in copper Content ≥ 99.95%.

[0016] The production process of the above-mentioned lead-based alloy for cable sheathing, the specific operation steps are as follows: adding a formula amount of lead into a lead smelting furnace, heating to 400-450 ° C, the lead is completely melted, adding an appropriate amount of slag remover, Turn on the mixer to stir, let the slag remover and lead slag fully react to powder, use special tooling to salvage the lead slag floating on the surface of the lead liquid, raise the temperature to 400-450 ℃, add th...

Embodiment 3

[0018] A lead-based alloy for cable sheath, which is prepared by melting the following components by weight percentage: antimony 0.25%, tin 0.5%, silver 0.025%, copper 0.01%, bismuth 0.07%, and the rest are lead, and lead in lead is 0.07%. Net content ≥99.994%, net content of antimony in antimony ≥99.0%, net content of tin in tin ≥99.9%, net content of bismuth in bismuth ≥99.997%, net content of silver in silver ≥99.99%, net content of copper in copper Content ≥ 99.95%.

[0019] The production process of the above-mentioned lead-based alloy for cable sheathing, the specific operation steps are as follows: adding a formula amount of lead into a lead smelting furnace, heating to 400-450 ° C, the lead is completely melted, adding an appropriate amount of slag remover, Turn on the mixer to stir, let the slag remover and lead slag fully react to powder, use special tooling to salvage the lead slag floating on the surface of the lead liquid, raise the temperature to 400-450 ℃, add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com