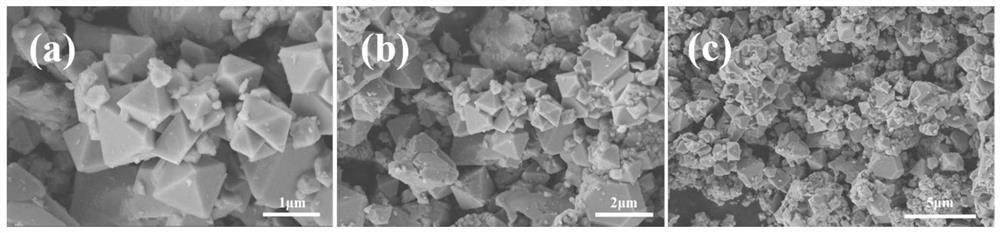

A preparation method of lithium nickel manganese oxide material with submicron octahedral structure

A technology of regular octahedron and lithium nickel manganese oxide, which is applied in the field of preparation of lithium nickel manganese oxide material with submicron octahedral structure, can solve the problem that the octahedral structure of lithium nickel manganese oxide material is not obvious, the degree of performance improvement is not obvious, and the method is cumbersome and other problems, to achieve the effect of obvious octahedral shape, cost-effective improvement, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

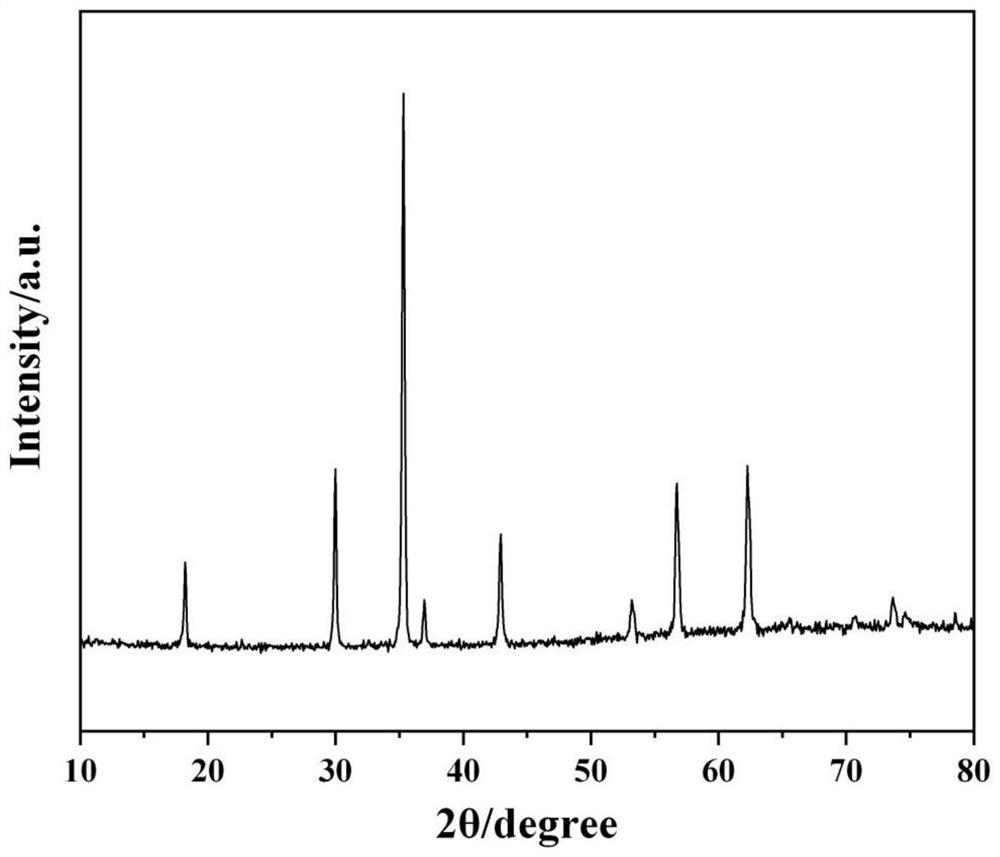

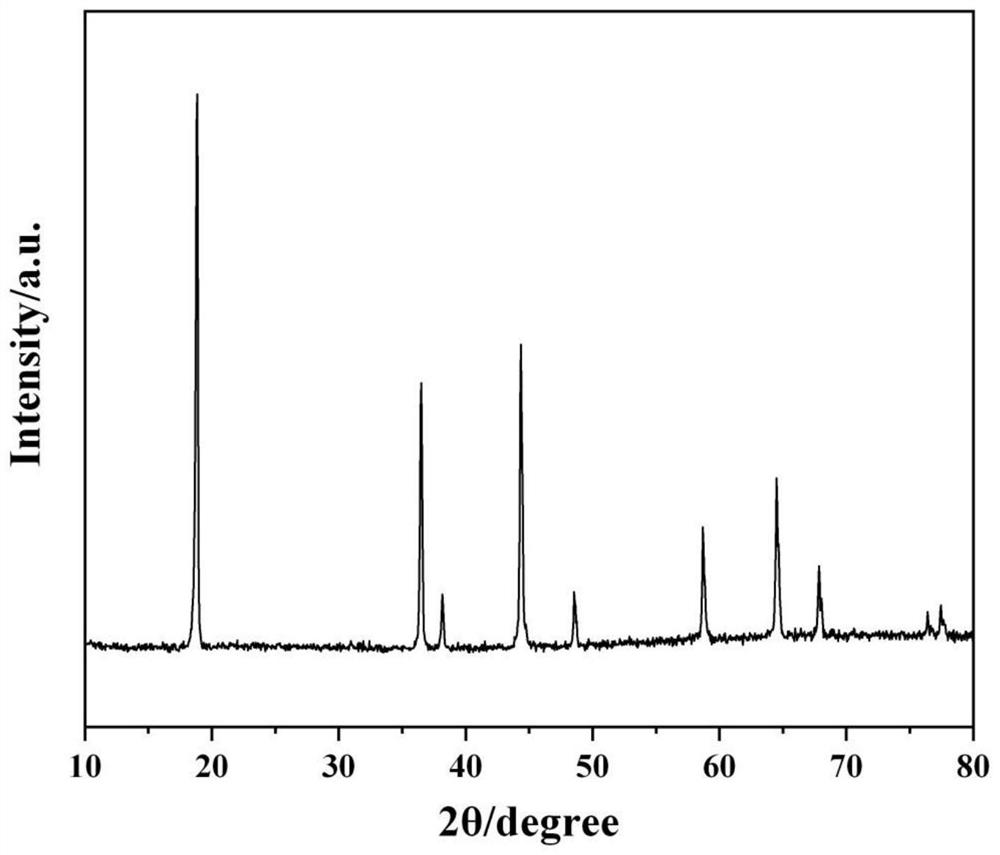

Embodiment 1

[0035] MnO 2 , Ni(NO 3 ) 2 ·6H 2 O and Li 2 CO 3 Prepared for raw materials. Manganese dioxide and Ni(NO 3 ) 2 ·6H 2 O and lithium carbonate are accurately weighed according to the ratio of stoichiometric ratio 3:1:1.05 (5% of lithium source is excessive to compensate for the loss at high temperature), and the manganese dioxide and Ni(NO 3 ) 2 ·6H 2 O is mixed and placed in a ball mill jar for ball milling. The ball milling speed is 400r / min, and the ball milling time is 3h. The manganese dioxide and Ni(NO 3 ) 2 ·6H 2 The mixture of O was dried into a powder in a forced air oven. The amount of weighing material is the oxalic acid powder of 2 (x+y+z) again, the above-mentioned oxalic acid powder is mixed with the manganese dioxide and Ni(NO 3 ) 2 ·6H 2 The mixture of O was mixed by ball milling, the ball milling speed was 400r / min, and the ball milling time was 3h. Add PEG with an amount greater than 2(x+y+z) to the ball-milled mixture, and stir for about 2 hou...

Embodiment 2

[0039] Take Mn(AC) 2 4H 2 O, Ni(AC) 2 4H 2 O and LiAC were prepared as raw materials. Mn(AC) 2 4H 2 O, Ni(AC) 2 4H 2 O and LiAC are accurately weighed according to the stoichiometric ratio of 3:1:2.1 (5% of the lithium source is excessive to compensate for the loss at high temperature), and the obtained Mn(AC) 2 4H 2 O and Ni(AC) 2 4H 2 O mixed and placed in a ball mill jar for ball milling, the ball milling speed is 600r / min, the ball milling time is 6h, the Mn(AC) obtained by ball milling 2 4H 2 O and Ni(AC) 2 4H 2 O Mixed Mn(AC) 2 4H 2 O and Ni(AC) 2 4H 2 The mixture of O is dry. The dried mixture was mixed with LiAC ball mill, with 1 mol / L oxalic acid solution as the dispersant, the milling speed was 200r / min, and the ball milling time was 5h. Add PEG2000 with an amount greater than 2 (x+y+z) to the ball-milled mixture, and stir for about 5 hours to obtain a black-gray jelly mixture, which is preheated at 300° C. for 2 h. The black-gray colloidal mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com