High-precision sucker mechanism used for optical fiber cable machining

A suction cup mechanism, fiber optic cable technology, applied in the direction of walking bridge cranes, cranes, load hanging components, etc., can solve the problems of high quality of steel and aluminum strips, reduce damage, reduce labor intensity, and improve feeding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

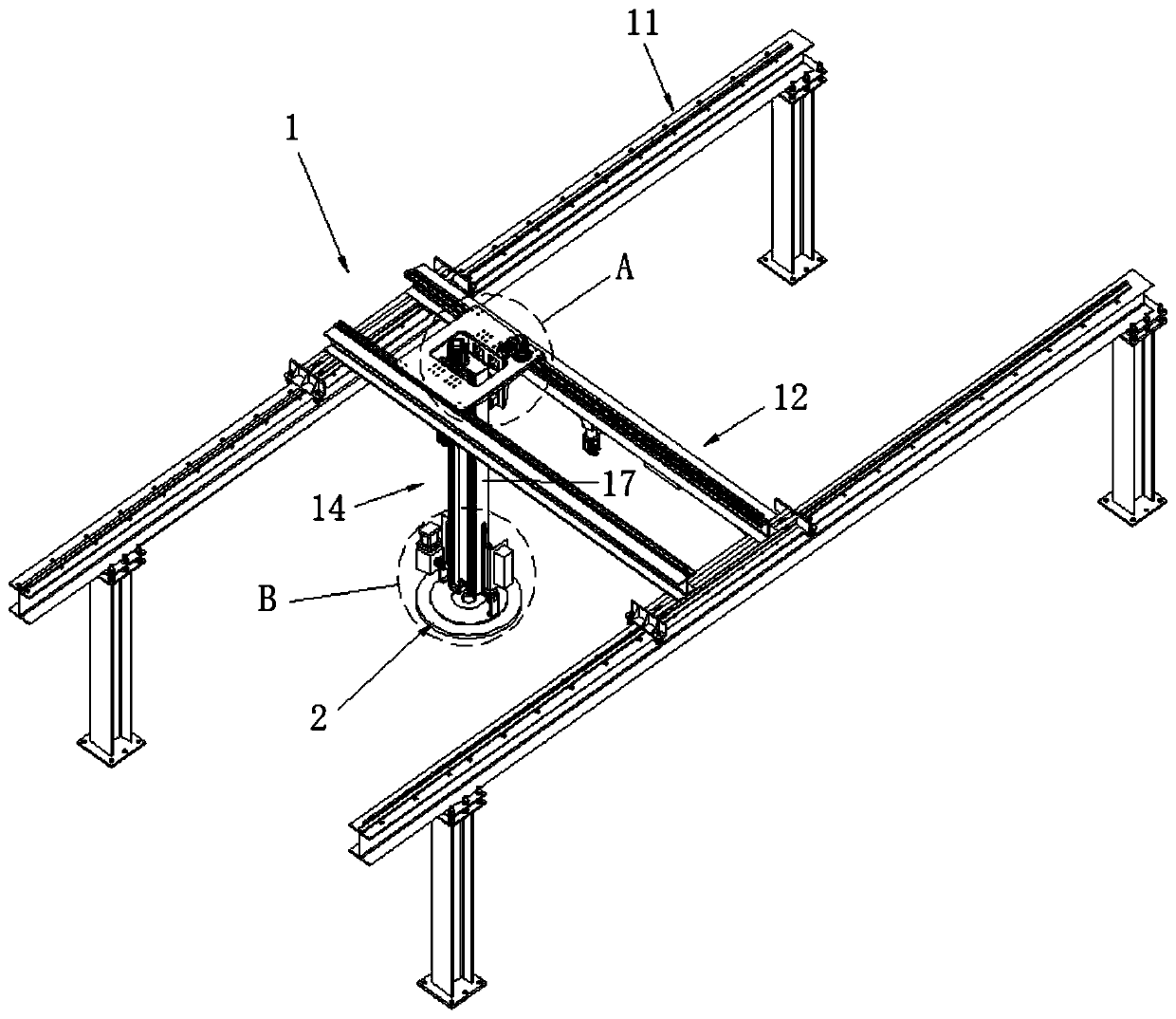

[0032] Embodiment 1: A high-precision sucker mechanism for optical fiber and cable processing, refer to the attached Figure 1-5 , including a suction cup assembly 2 installed on a displacement mechanism 1, the displacement mechanism 1 includes an X-axis assembly 11, a Y-axis assembly 12 and a Z-axis assembly 14, and the Y-axis assembly 12 is movably mounted on the X-axis assembly 11 , the Z-axis assembly 14 is connected to the Y-axis assembly 12 and can move along the Y-axis direction, and the suction cup assembly 2 is mounted on the Z-axis assembly 14 and can move along the Z-axis direction;

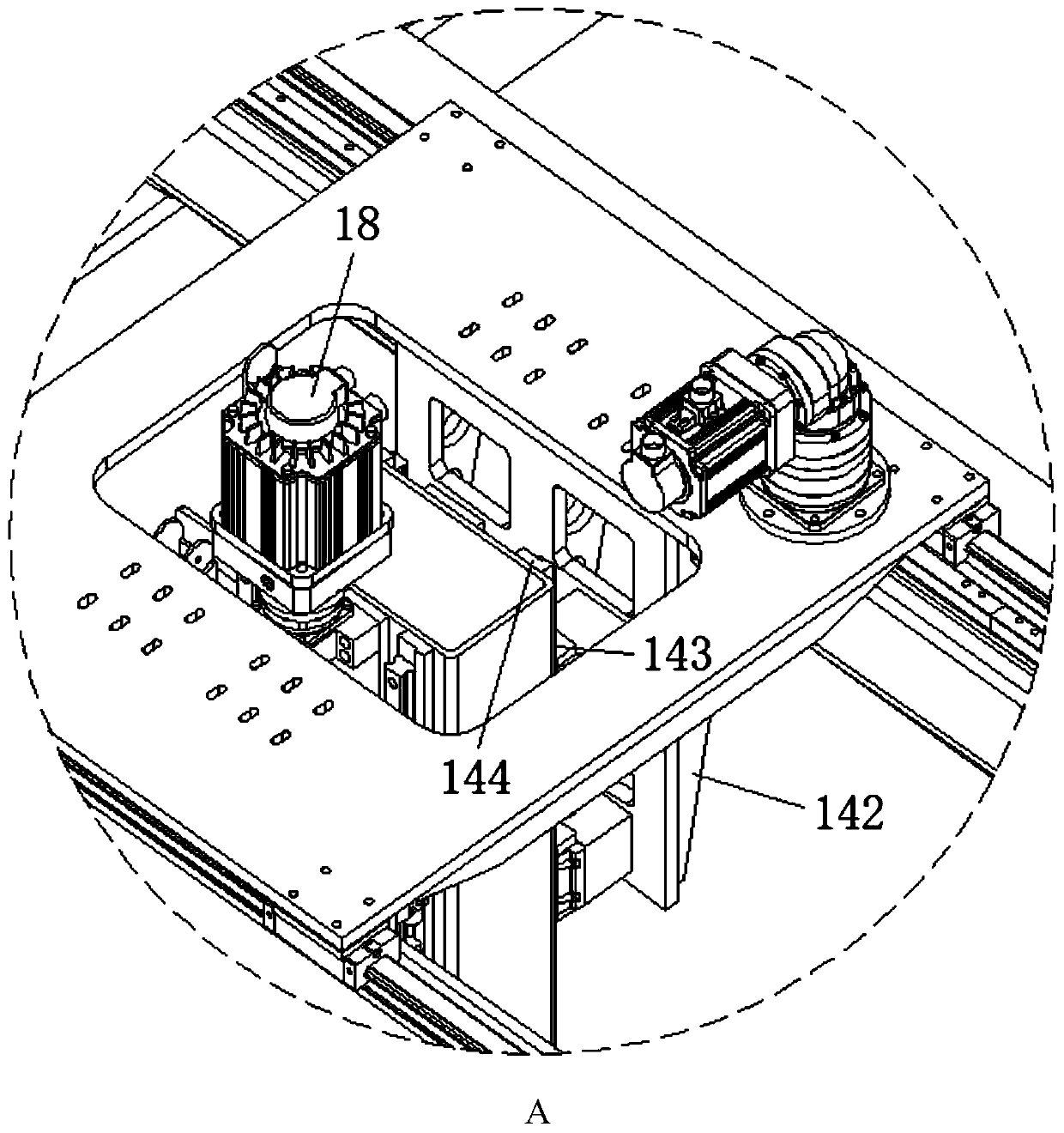

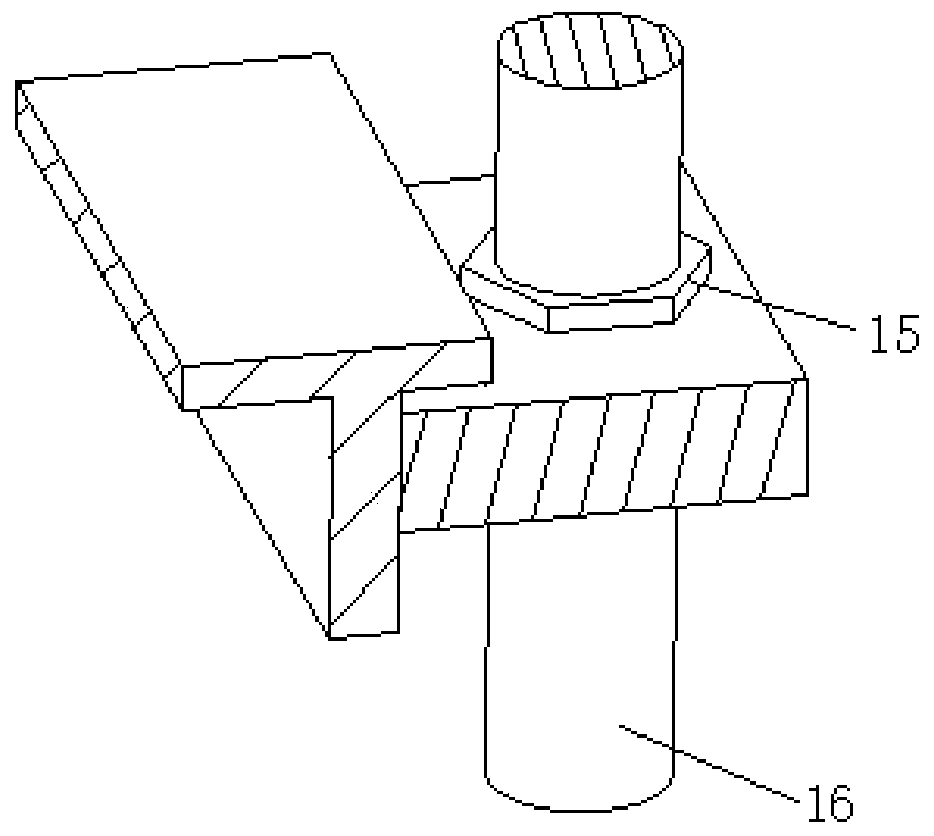

[0033] The Z-axis assembly 14 further includes a drive nut 15, a drive screw 16, a movable column 17 and a Z-axis motor 18. The drive nut 15 is sleeved on the drive screw 16 and is connected to the Y-axis assembly 12. The Z-axis motor 18 is connected with the driving screw rod 16 for driving the driving screw rod 16 to rotate;

[0034]The suction cup assembly 2 includes a vacuum pump ...

Embodiment 2

[0041] Embodiment 2: A high-precision sucker mechanism for optical fiber and cable processing, refer to the attached Figure 1-5 , including a suction cup assembly 2 installed on a displacement mechanism 1, the displacement mechanism 1 includes an X-axis assembly 11, a Y-axis assembly 12 and a Z-axis assembly 14, and the Y-axis assembly 12 is movably mounted on the X-axis assembly 11 , the Z-axis assembly 14 is connected to the Y-axis assembly 12 and can move along the Y-axis direction, and the suction cup assembly 2 is mounted on the Z-axis assembly 14 and can move along the Z-axis direction;

[0042] The Z-axis assembly 14 further includes a drive nut 15, a drive screw 16, a movable column 17 and a Z-axis motor 18. The drive nut 15 is sleeved on the drive screw 16 and is connected to the Y-axis assembly 12. The Z-axis motor 18 is connected with the driving screw rod 16 for driving the driving screw rod 16 to rotate;

[0043] The suction cup assembly 2 includes a vacuum pump...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap