Nickel-based high-temperature alloy turbine supporting base argon arc welding repairing method

A technology of nickel-based superalloy and repair method, which is applied in the direction of arc welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of long maintenance cycle, high replacement cost, welding cracks, etc., and reduce the cost of use and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

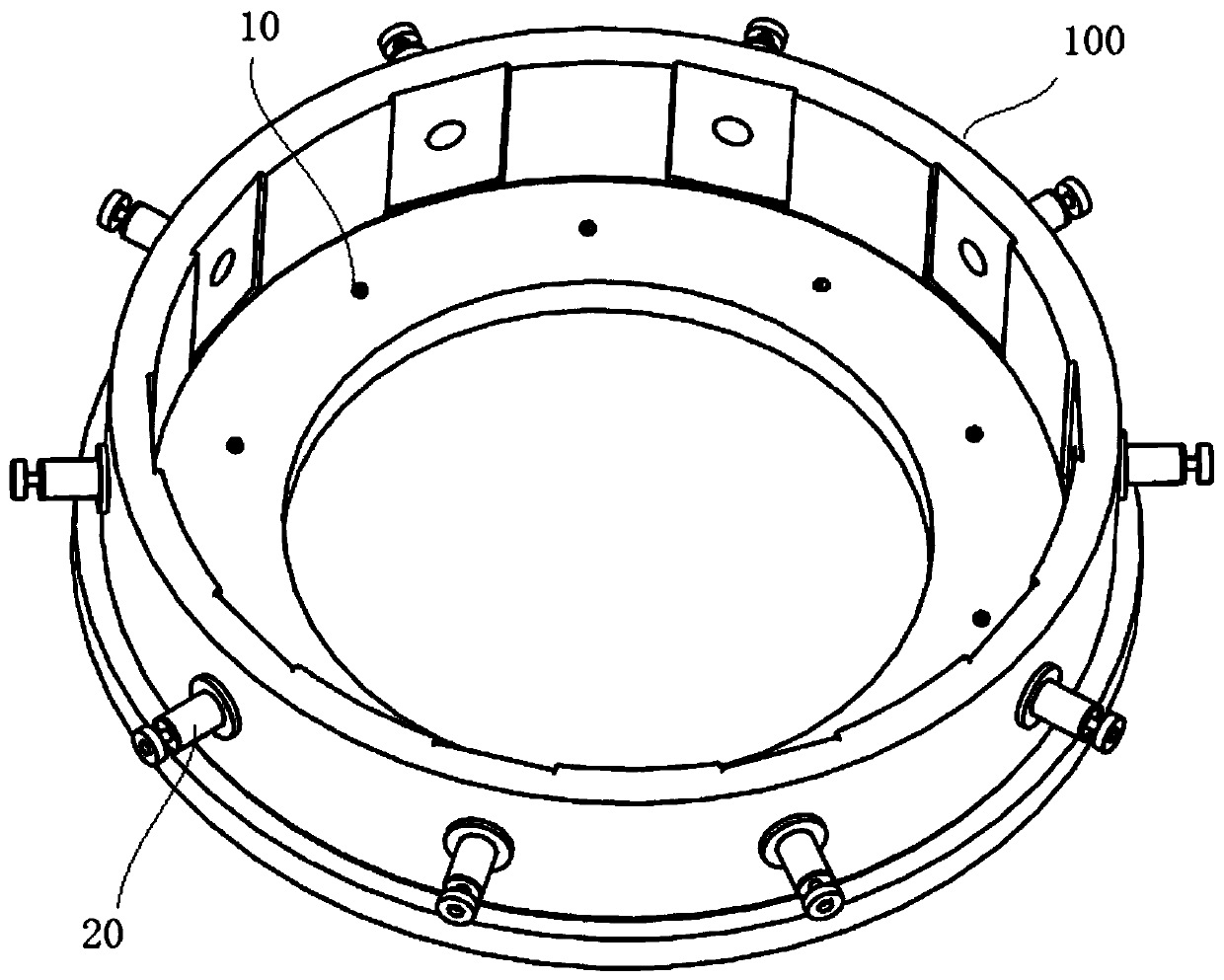

[0019] see figure 1 , when a certain type of engine was refurbished, it was found that fatigue cracks easily appeared near the welding seam at the joint between the connecting pipe and the outer ring of the nickel-based superalloy turbine support seat, and the cracks extended to the unwelded base metal area. Design the back protection device, anti-deformation tooling, and adopt short tungsten pole segmented welding. The implementation steps are as follows:

[0020] 1. Confirmation of cracks in the connecting pipe of the turbine support seat

[0021] The turbine support seat of a certain type of engine is made of GH163 nickel-based superalloy. During the renovation of the turbine support seat, it was found that there were ten small-diameter tubes welded on the inner cylinder, eight of which had fatigue cracks near the welds. The long one is about 20mm.

[0022] 2. Repair process and inspection, nickel-based superalloy turbine support seat argon arc welding repair method, incl...

Embodiment 2

[0031] see figure 1 , when a certain type of engine was refurbished, it was found that fatigue cracks easily appeared near the welding seam at the joint between the connecting pipe and the outer ring of the nickel-based superalloy turbine support seat, and the cracks extended to the unwelded base metal area. Design the back protection device, anti-deformation tooling, and adopt short tungsten pole segmented welding. The implementation steps are as follows:

[0032] 1. Confirmation of cracks in the connecting pipe of the turbine support seat

[0033] The turbine support seat of a certain type of engine is made of GH163 nickel-based superalloy. During the renovation of the turbine support seat, it was found that there were ten small-diameter tubes welded on the inner cylinder, and fatigue cracks appeared in six of them near the weld seam. The longest is about 18mm.

[0034] 2. The repair process and inspection, the argon arc welding repair method of the nickel-based superalloy...

Embodiment 3

[0043] see figure 1 , when a certain type of engine was refurbished, it was found that fatigue cracks easily appeared near the welding seam at the joint between the connecting pipe and the outer ring of the nickel-based superalloy turbine support seat, and the cracks extended to the unwelded base metal area. Design the back protection device, anti-deformation tooling, and adopt short tungsten pole segmented welding. The implementation steps are as follows:

[0044] 1. Confirmation of cracks in the connecting pipe of the turbine support seat

[0045]The turbine support seat of a certain type of engine is made of GH163 nickel-based superalloy. During the renovation of the turbine support seat, it was found that there were ten small-diameter tubes welded on the inner cylinder, nine of which had fatigue cracks near the weld. The long one is about 19mm.

[0046] 2. Repair process and inspection, nickel-based superalloy turbine support seat argon arc welding repair method, includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com