Water medium separation device for small-scale copper-aluminum mixed waste blocks after dismantling of electrical appliances

A separation device, small-scale technology, applied in wet separation, solid separation, chemical instruments and methods, etc., can solve problems such as difficulty, and achieve the effect of overcoming slow speed, low labor intensity, and fast sorting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

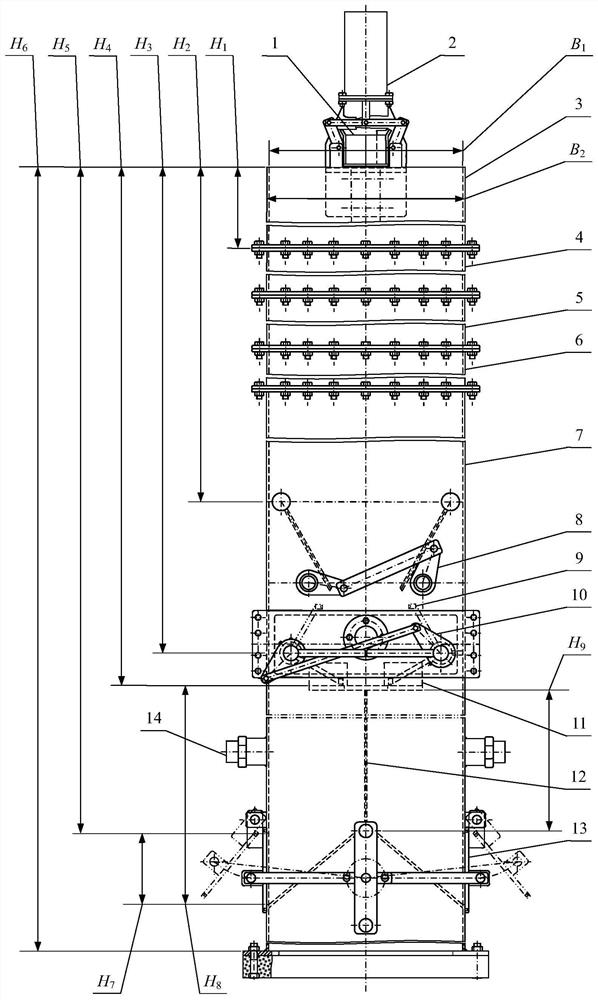

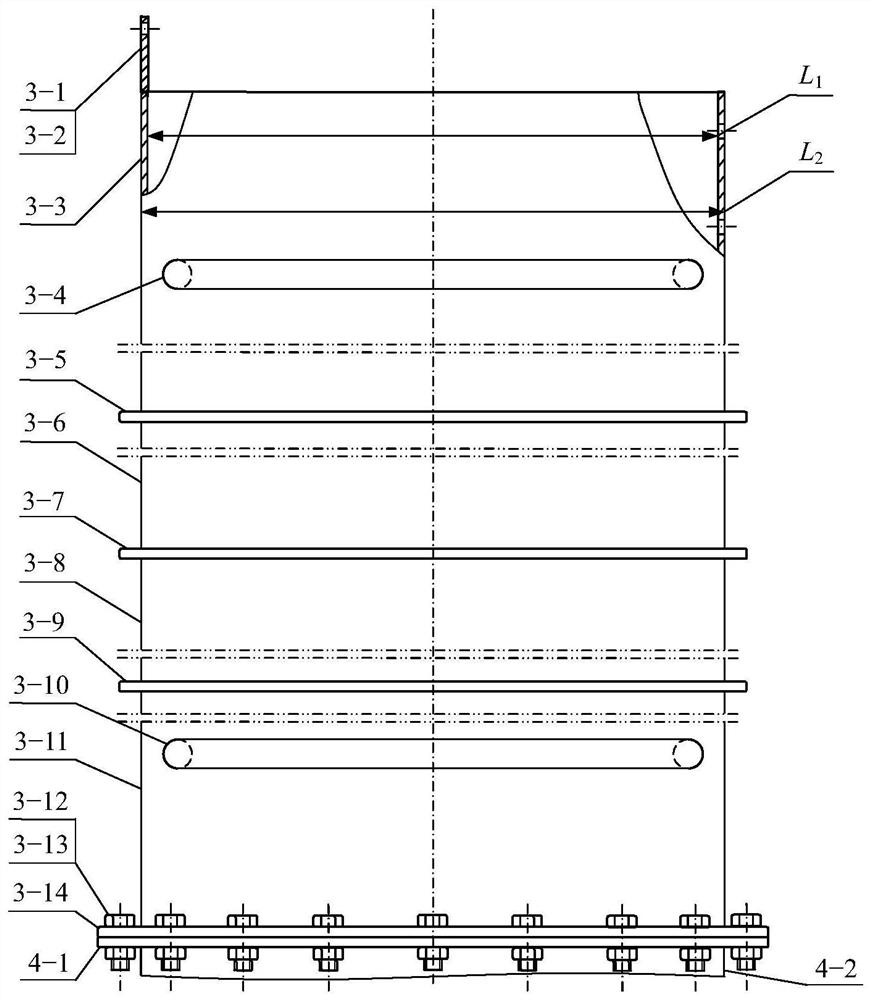

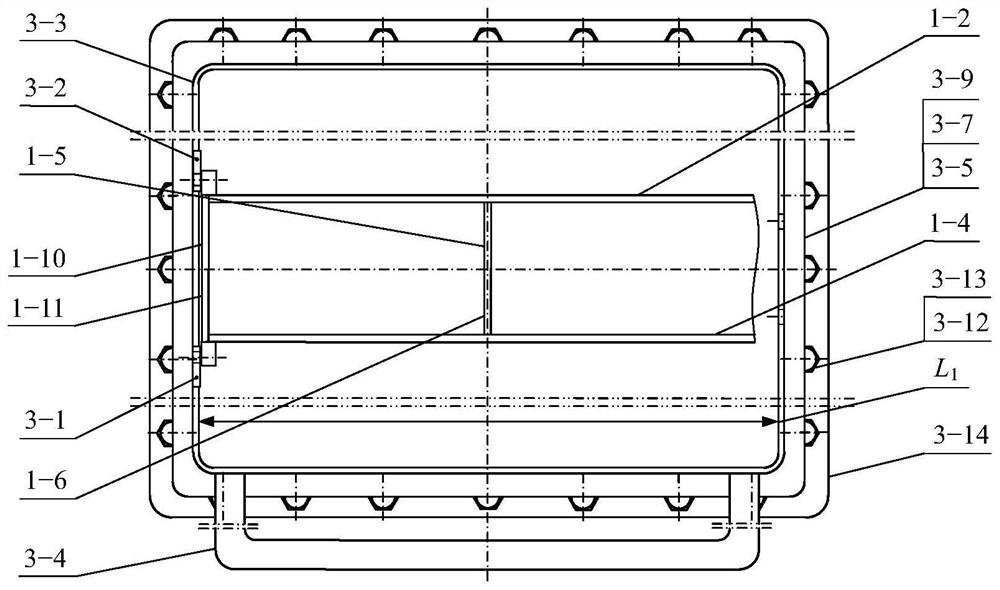

[0088] to combine figure 1 As shown, a water-medium separation device for small-scale copper-aluminum mixed waste blocks in electrical appliances, the water tank assembly includes a first water-saving tank assembly 3, a second water-saving tank assembly 4, and a third water-saving tank connected sequentially from top to bottom Component 5, the fourth section water storehouse assembly 6, the fifth section water storehouse assembly 7. Wherein, the upper end of the first water-saving bin assembly 3 is equipped with a supply hopper assembly 1 and a supply hopper action actuator 2 for controlling the opening and closing of the supply hopper assembly 1 . The fifth section of water tank component 7 is installed in order from top to bottom with yaw material accumulation and water partition component 8, unloading w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com