Lithium ion battery negative electrode and preparation method thereof

A technology of lithium ion battery and negative electrode, applied in the field of lithium ion battery negative electrode and its preparation, can solve the problems of peeling, reduction of negative electrode active material, pulverization of active material, etc., and achieves stable performance, large reaction area and good electrochemical reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

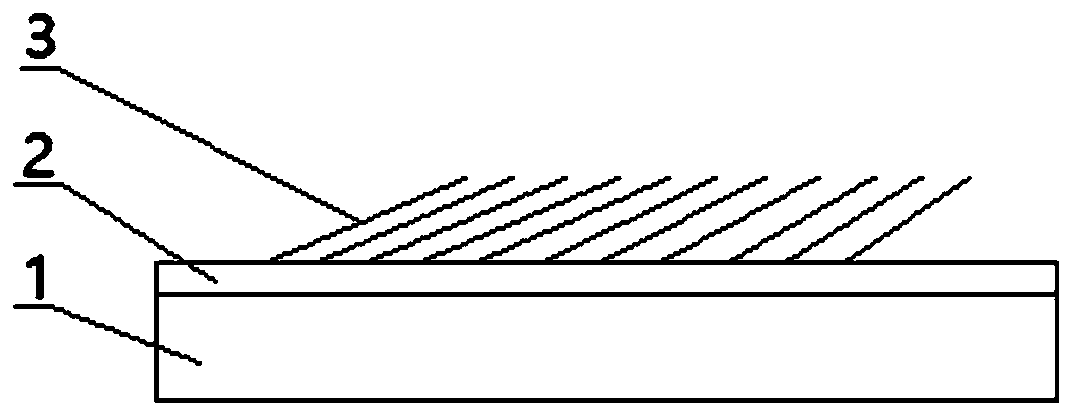

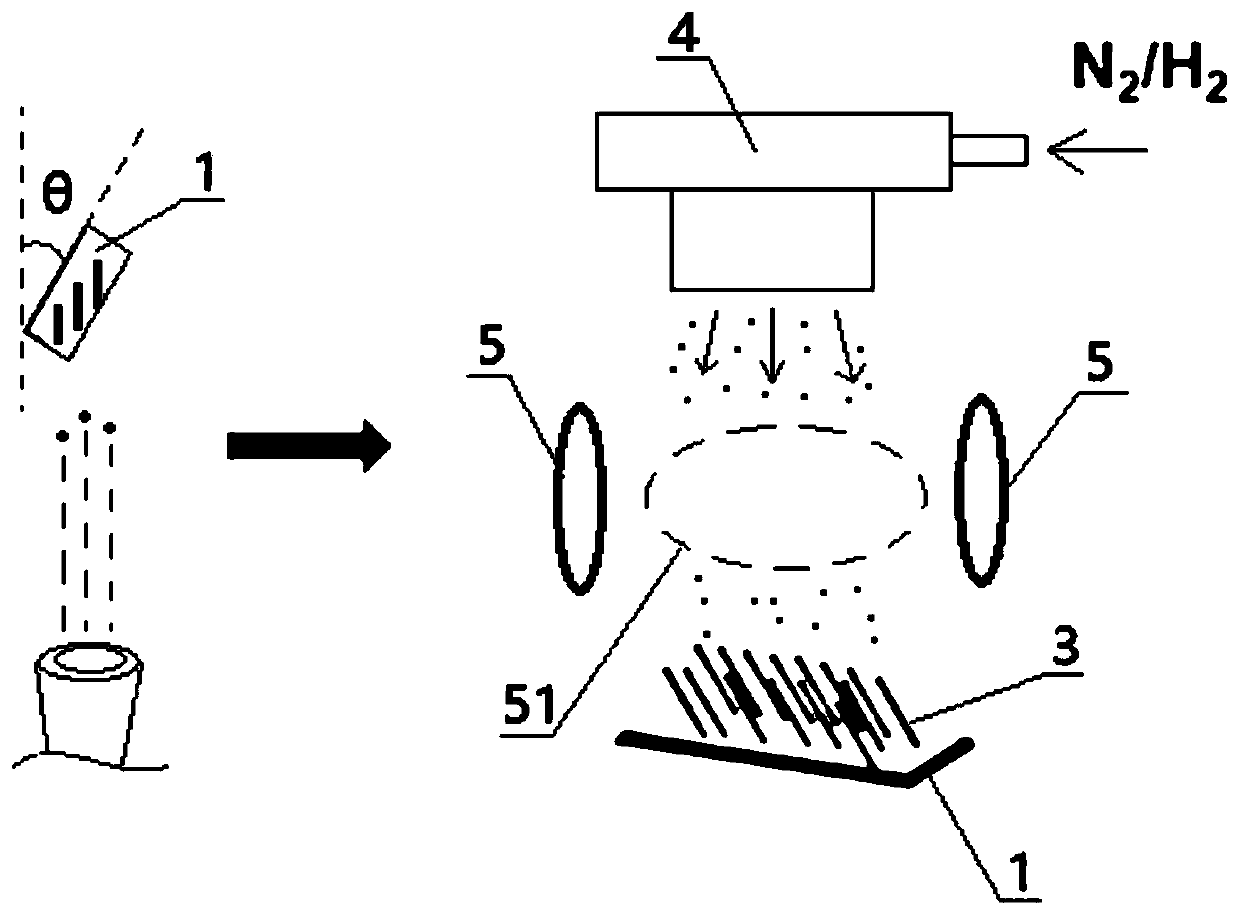

[0041] Please refer to image 3 , the present invention also provides a kind of preparation method of above-mentioned negative electrode of lithium ion battery, comprises the steps:

[0042] A stainless steel sheet is used as the substrate 1;

[0043] To clean the stainless steel sheet, the cleaning agent is at least one of acetone or ethanol;

[0044] A Ti layer 2 with a thickness of 80-120 nm is provided on the stainless steel sheet by magnetron sputtering;

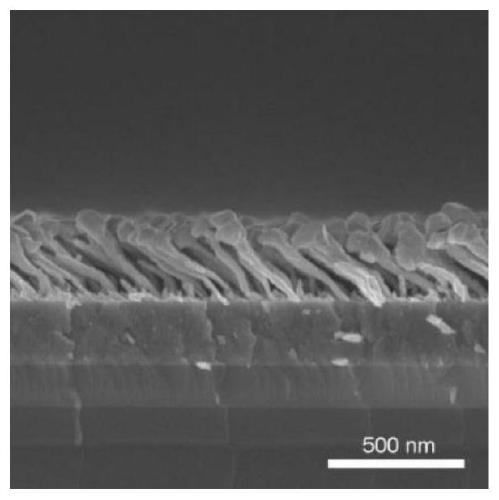

[0045] A nanowire array of Ni material is deposited as an electrode film layer 3 on the substrate 1 provided with a Ti layer 2 by electron beam evaporation; Depositing on the substrate 1 at a grazing angle, the angle θ of the grazing angle deposition is 8-15 degrees; the deposition rate of the Ni nanowire array is 0.25-0.35nm·s -1 , the deposition thickness on the substrate 1 is 450-550nm;

[0046] Move the substrate 1 deposited with the Ni material nanowire array to the selenization chamber 4;

[0047] Put 3-4g of...

Embodiment 1

[0052] This embodiment provides a method for preparing a negative electrode of a lithium ion battery, comprising the following steps:

[0053] A stainless steel sheet is used as the substrate 1; in the present embodiment, a square stainless steel sheet with a side length of 1 cm is preferred;

[0054] To clean the stainless steel sheet, the cleaning agent is acetone;

[0055] A Ti layer 2 with a thickness of 80 nm is set on the stainless steel sheet by magnetron sputtering;

[0056]A nanowire array of Ni material is deposited as an electrode film layer 3 on the substrate 1 provided with a Ti layer 2 by electron beam evaporation; Deposited on the substrate 1 at a grazing angle, the angle θ of the grazing angle deposition is 8 degrees; the deposition rate of the Ni nanowire array is 0.25nm·s -1 , the deposition thickness on the substrate 1 is 450nm;

[0057] Move the substrate 1 deposited with the Ni material nanowire array to the selenization chamber 4;

[0058] Put the Se ...

Embodiment 2

[0063] The present invention also provides a method for preparing the negative electrode of the lithium ion battery, comprising the steps of:

[0064] A stainless steel sheet is used as the substrate 1; in the present embodiment, a square stainless steel sheet with a side length of 2 cm is preferred;

[0065] To clean the stainless steel sheet, the cleaning agent is ethanol;

[0066] A 120nm thick Ti layer 2 is provided on the stainless steel sheet by magnetron sputtering;

[0067] A nanowire array of Ni material is deposited as an electrode film layer 3 on the substrate 1 provided with a Ti layer 2 by electron beam evaporation; Deposited on the substrate 1 at a grazing angle, the angle θ of the grazing angle deposition is 15 degrees; the deposition rate of the Ni nanowire array is 0.35nm·s -1 , the deposition thickness on the substrate 1 is 550nm;

[0068] Move the substrate 1 deposited with the Ni material nanowire array to the selenization chamber 4;

[0069] Put the Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com