Special tool for installing carbon powder ink cartridge of laser printer

A technology of laser printers and special tools, applied in the field of toner, can solve the problems of difficult input of toner, unevenness in the interior, concentrated and agglomerated state, and unsatisfactory effect, so as to achieve the effect of ensuring the printing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

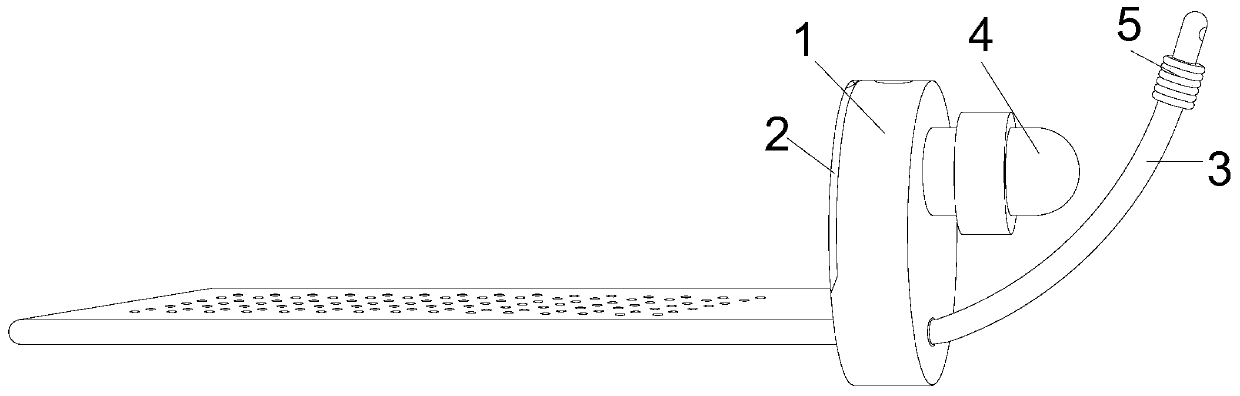

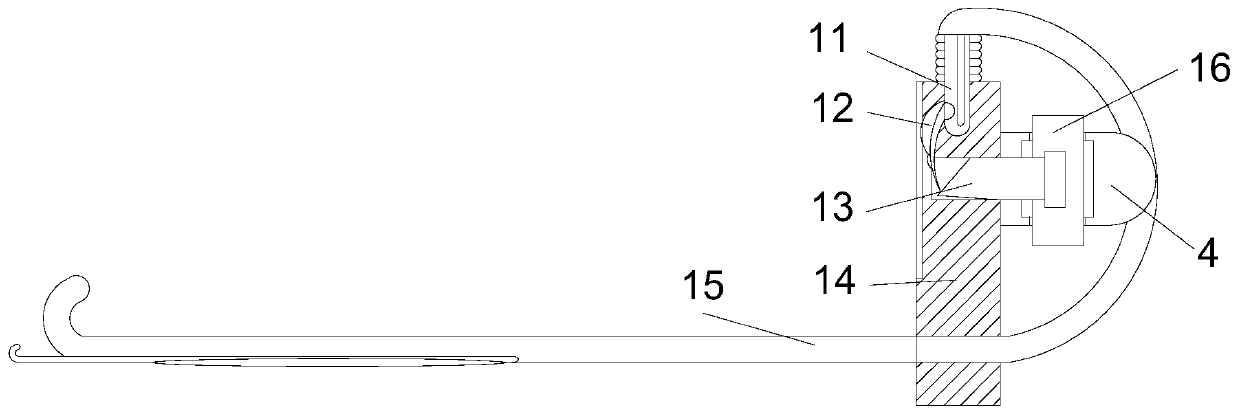

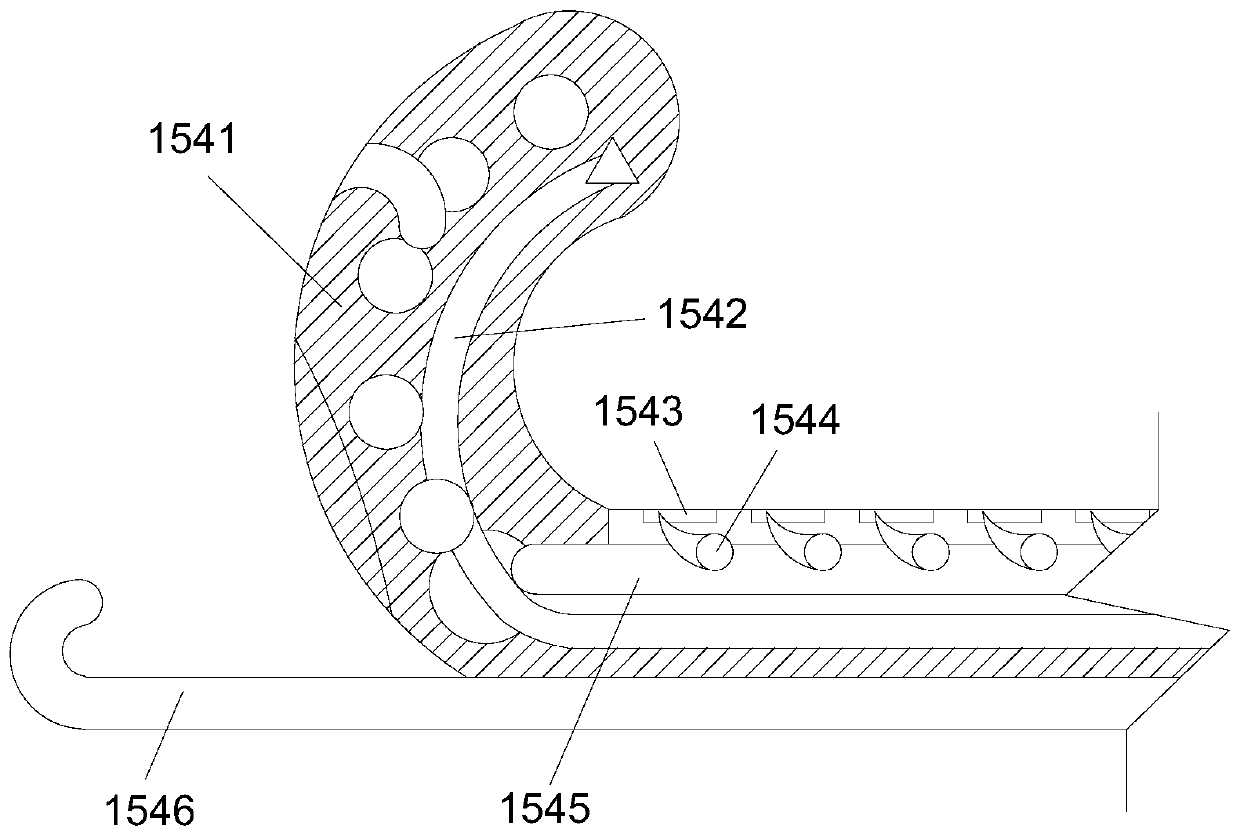

[0031] as attached figure 1 to attach Figure 7 Shown:

[0032] The invention provides a special tool for installing a toner cartridge in a laser printer. The left end is fixed with a soft rubber patch 2, the left end of the auxiliary strip 3 is installed on the lower right end of the special adjusting device 1 by embedding, and the left end of the cladding rod 4 is fixedly connected to the right end of the special adjusting device 1 by means of electric welding , the elastic sleeve 5 is fixedly installed on the top of the auxiliary bar 3, and the special adjustment device 1 includes a cut-off intubation tube 11, a point buckle handle 12, a height dislocation rod 13, an attachment plate 14, an adjustment plate 15, and a snap joint Ring 16, the top of the cut-off intubation tube 11 is fixedly connected with the auxiliary bar 3, the bottom end of the cut-off intubation tube 11 is installed on the top of the attachment plate 14 by embedding, and the top of the right side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com