A high-temperature furnace reclaiming clamp

A technology for high-temperature furnaces and reclaiming clips, which is applied in the direction of furnaces, furnace components, and program-controlled manipulators. It can solve problems such as the inability to flip the grippers vertically, hinder the transfer of mechanical hands between positions, and reduce work efficiency. It achieves compact connection, Accurate clamping and improved mechanical automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

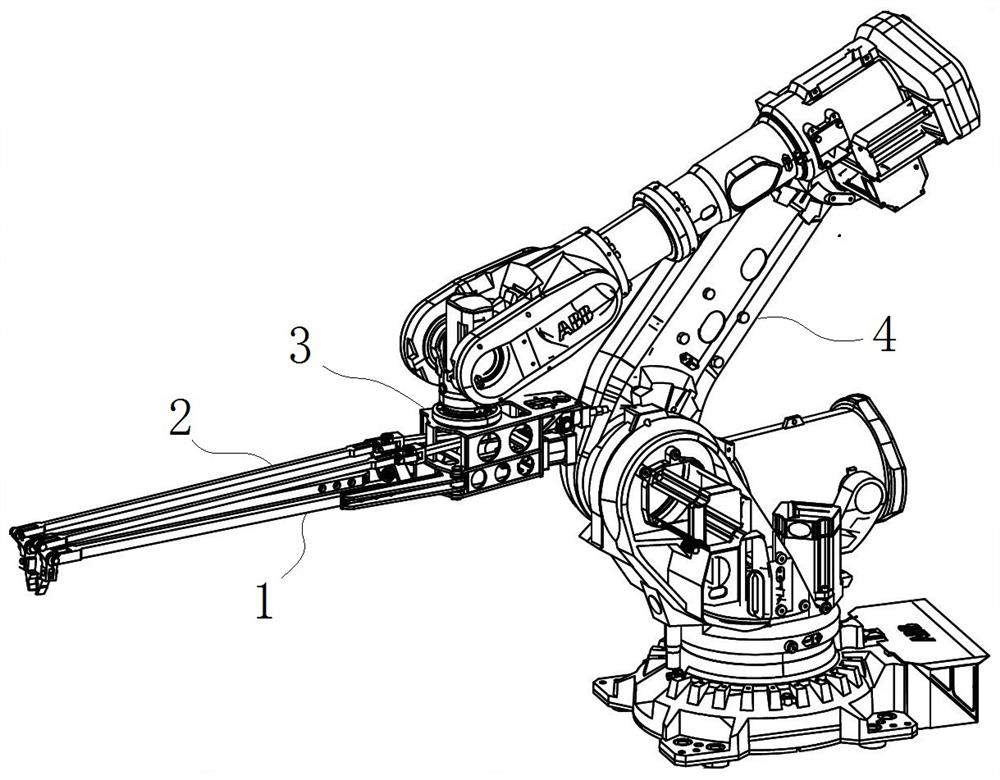

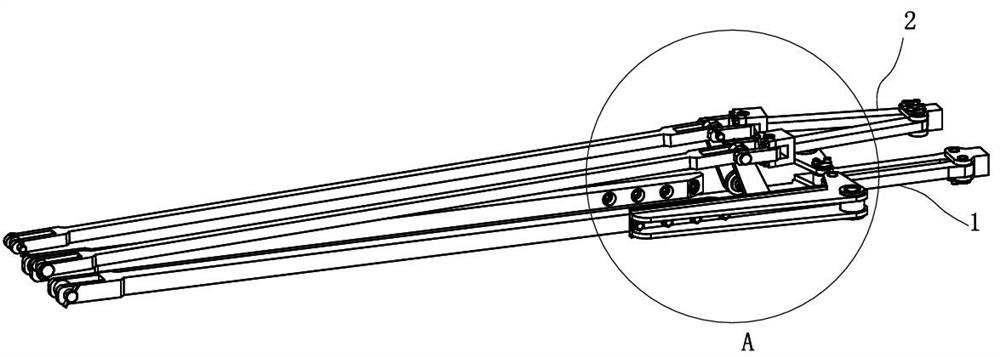

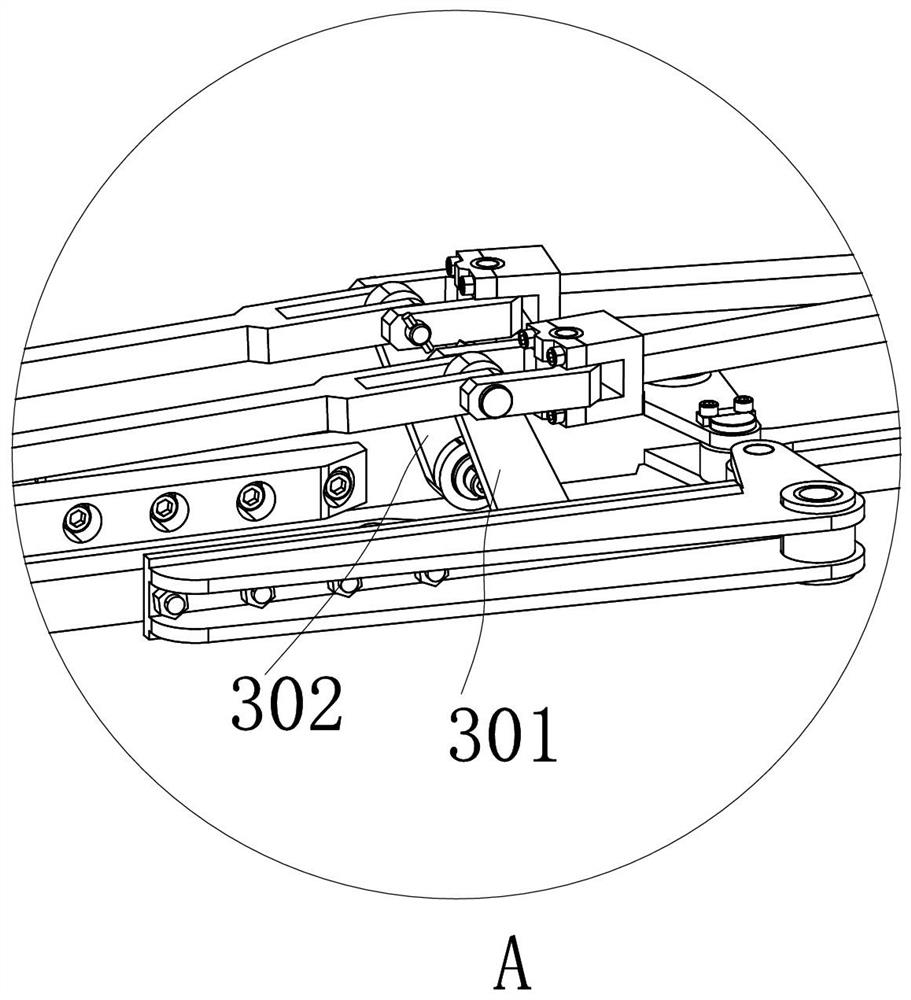

[0023] as attached Figure 1-8 As shown, the present invention includes an automatic manipulator 4, a clamp seat 3 installed on the clamp arm of the automatic manipulator 4, a transverse clamping device 2 installed at one end in the clamp seat 3, and a longitudinal overturning device 1 connected to the transverse clamping device 2; The longitudinal overturning device 1 is correspondingly installed above the transverse clamping device 2; the transverse clamping device 2 includes a clamping drive device, a lower connecting rod installed laterally on the clamping driving device, and a clamp mounted on the end of the lower connecting rod. Tightening plate and the corresponding jaws installed on the clamping plate; the lower connecting rod is connected with the clamp seat 3; the longitudinal overturning device 1 includes an overturning drive device and an upper link horizontally installed on the overturning drive device ; The end of the upper link is connected with the clamping pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com