A kind of aerated concrete wall panel installation method

A technology of aerated concrete and installation method, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of safety, difficult handling and installation, low construction efficiency, etc., and achieves convenient and fast construction, convenient adjustment, Ease of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

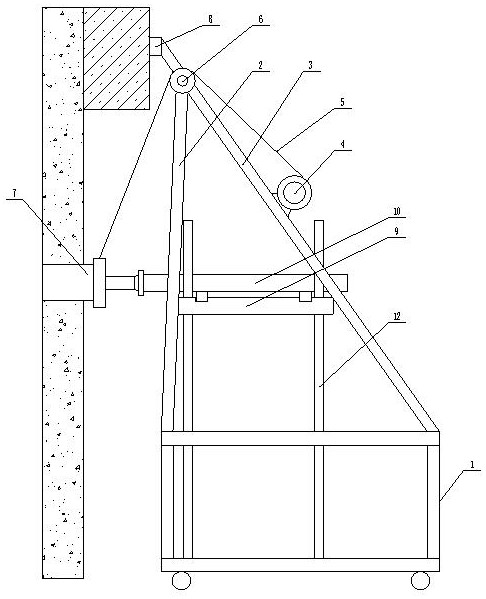

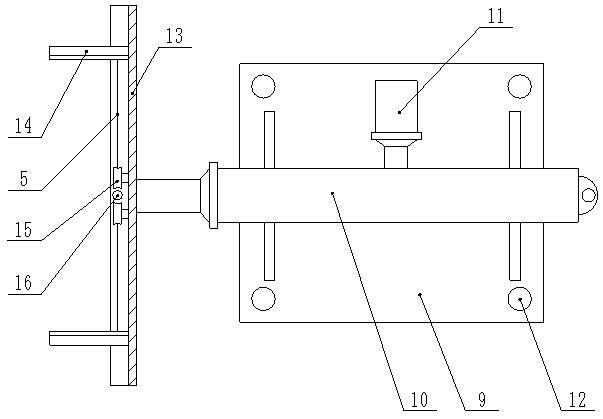

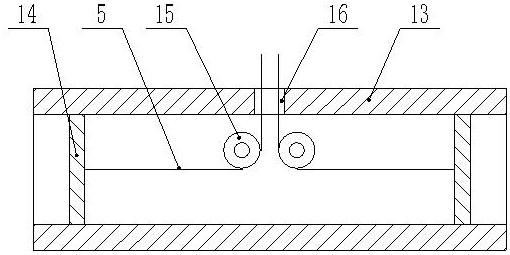

[0027] Example: as Figure 1-3 ,

[0028] A method for installing aerated concrete wall panels, comprising the following steps:

[0029] In the specific construction, the general aerated concrete wall panel is installed on the outside of the beam, the upper end is connected with the upper floor or the reserved steel bar on one side of the beam, and the lower end is connected with the reserved steel bar on the lower floor. The traditional installation method is, Set up scaffolding on the outside of the building, build a simple lifting device with steel pipes on the inside of the building, use wire ropes or slings to hoist the wall panels, and then manually adjust, because the wall panels are located on the outer surface of the building, and the danger is high. Construction workers on scaffolding pose a greater safety risk. Therefore, in order to improve construction efficiency and construction safety, the present invention firstly installs the wallboard into a wallboard fixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com