Three-coordinate image measuring instrument platform vertical fine adjustment device and implementation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

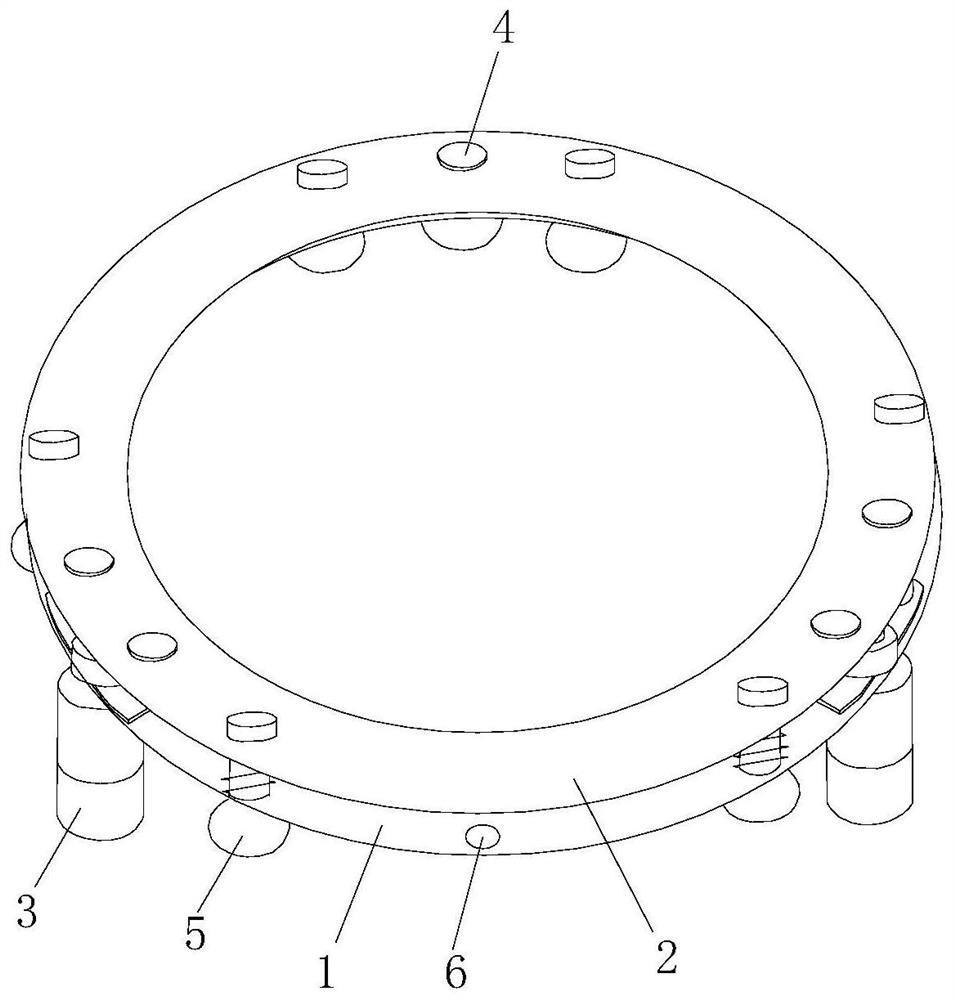

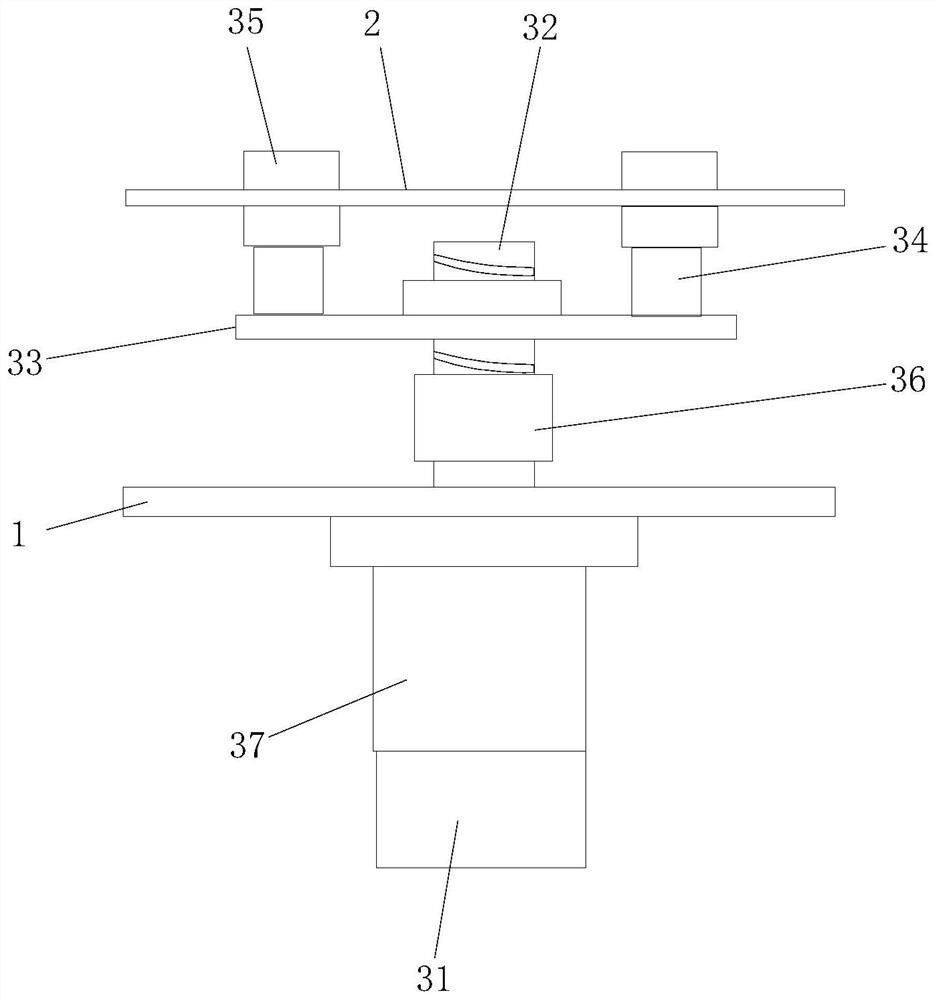

[0036] see Figure 1-4 , the present invention provides the following technical solutions: a vertical fine-tuning device for a three-coordinate image measuring instrument platform, including a base 1, a table 2 is arranged above the base 1, and the base 1 and the table 2 are connected by three adjustment components, and three The adjustment components are distributed in a circular array, and the two sides of the adjustment components are respectively provided with tensioning guide sleeve components 5 .

[0037] Further, the three adjusting components are two lifting components 3 and one fixing component 4 respectively.

[0038] By adopting the above-mentioned technical scheme, according to the principle of determining the plane by three points, the table top 2 is adjusted through three adjustment components, so as to realize the vertical adjustment of the key measurement position of the workpiece to be measured, so that the measuring instrument can realize accurate measurement...

Embodiment 2

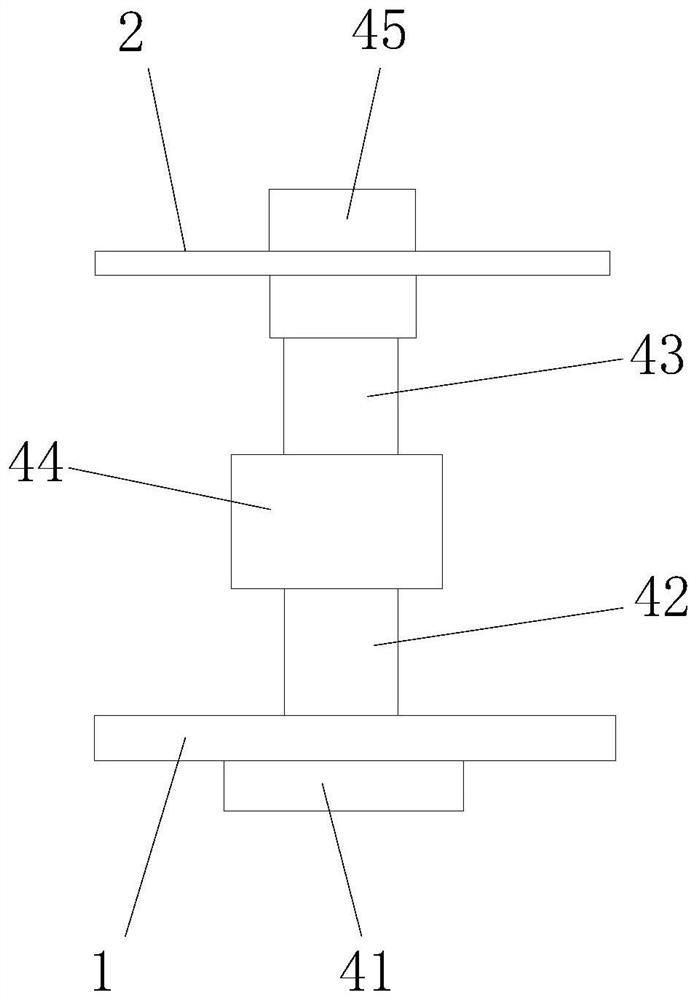

[0050] The difference between this embodiment and Embodiment 1 is that further, the tensioning guide sleeve assembly 5 includes a limit block 51, a guide post 53, a spring 54 and a third bolt 55, wherein the two ends of the guide post 53 are respectively connected to the base 1 and the table top 2 are slidingly connected, the upper end of the guide post 53 is connected with a third bolt 55, the lower end of the guide post 53 is connected with a limit block 51, the circumference of the guide post 53 is provided with a spring 54, and the spring 54 is located between the base 1 and the table top 2 Between, two ends of the spring 54 are provided with washers 52 .

[0051] By adopting the above technical solution, the tension between the base 1 and the table top 2 is tightened by the tension guide sleeve assembly 5 to prevent loosening, and it is possible to avoid a large left-right deviation when the table top 2 is adjusted.

[0052] Further, the implementation method of the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com