Ground milling machine with swivel travel gear

A technology of walking device and milling machine, which is applied in the field of ground milling machines, can solve the problems of machine weight increase and production cost increase, and achieve the effect of light weight share and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

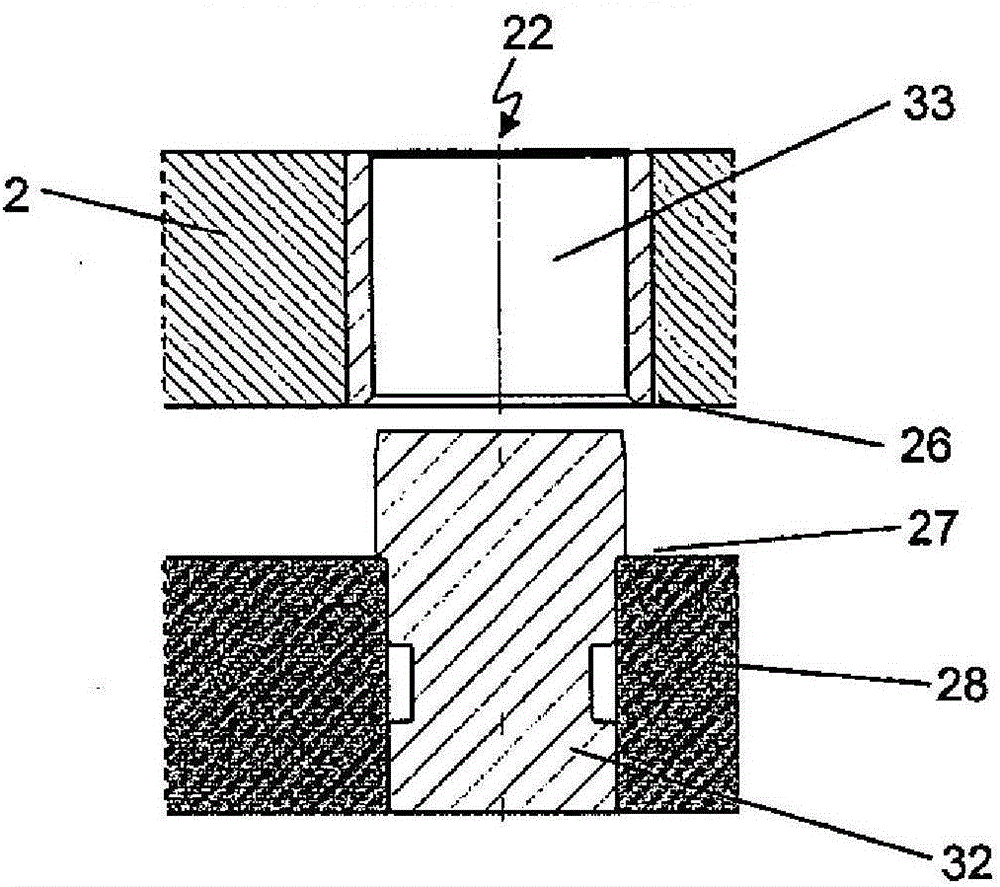

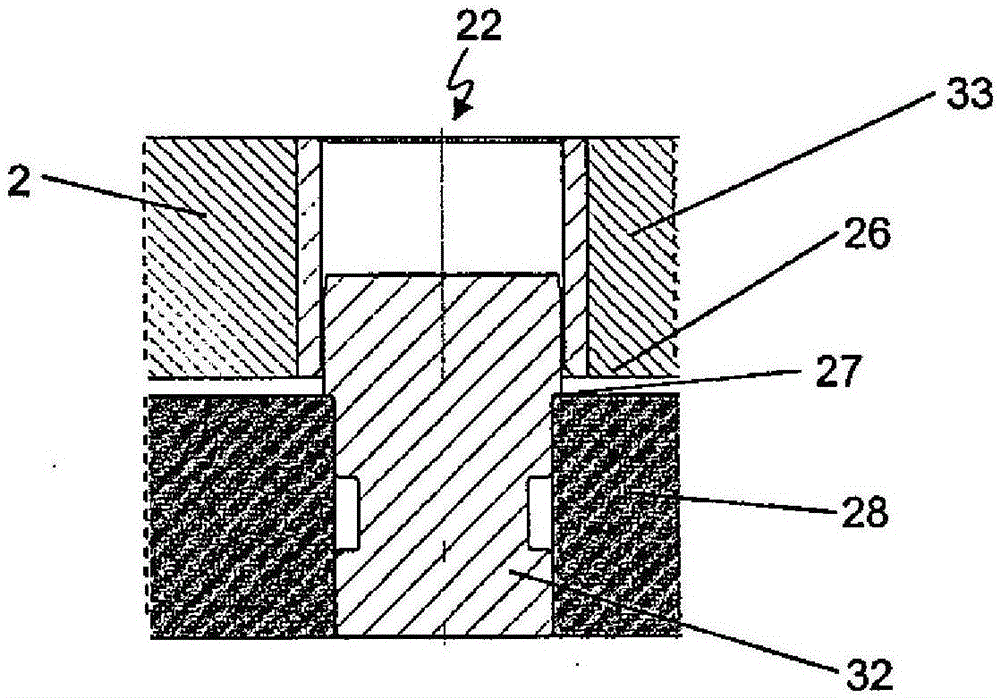

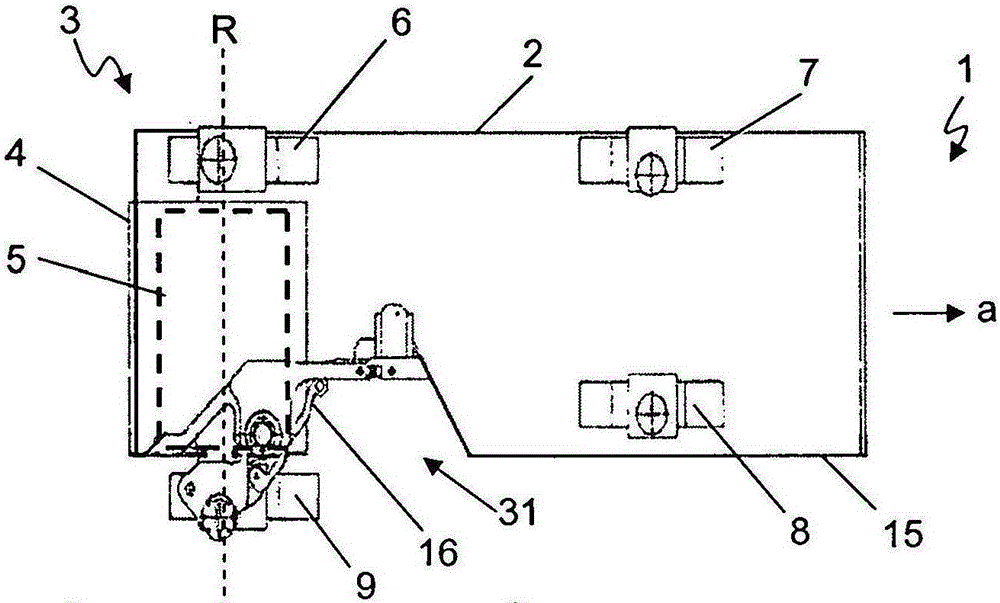

[0035] Identical components are represented by the same reference numerals in the figures, but components that are repeated in multiple figures are not individually identified in each figure. Figure 1a and 1b A plan view of the construction machine 1 is shown, in which only the main components are shown: the frame, the running gear, the milling device and the device for load relief. Other components, such as drives, operating stations, etc., are omitted for the sake of clarity, which are Figure 1c shown in side view. figure 2 and 3 It is a perspective view of the area of the rear running gear of the construction machine viewed obliquely from the front right. The main parts of the chassis are only represented by dashed lines so that they can be seen from other perspectives depending on the emphasis Figure 1a and 1b components shown in . FIGS. 4 a and 4 b also relate to sub-regions of the construction machine, in particular the region of the machine frame in which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com