Prefabricated reinforced concrete shear wall

A reinforced concrete and shear wall technology, applied in the direction of walls, buildings, building types, etc., can solve the problems of reduced wall sealing performance and low earthquake resistance, so as to improve the connection stability and avoid the impact of the service life of the wall Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

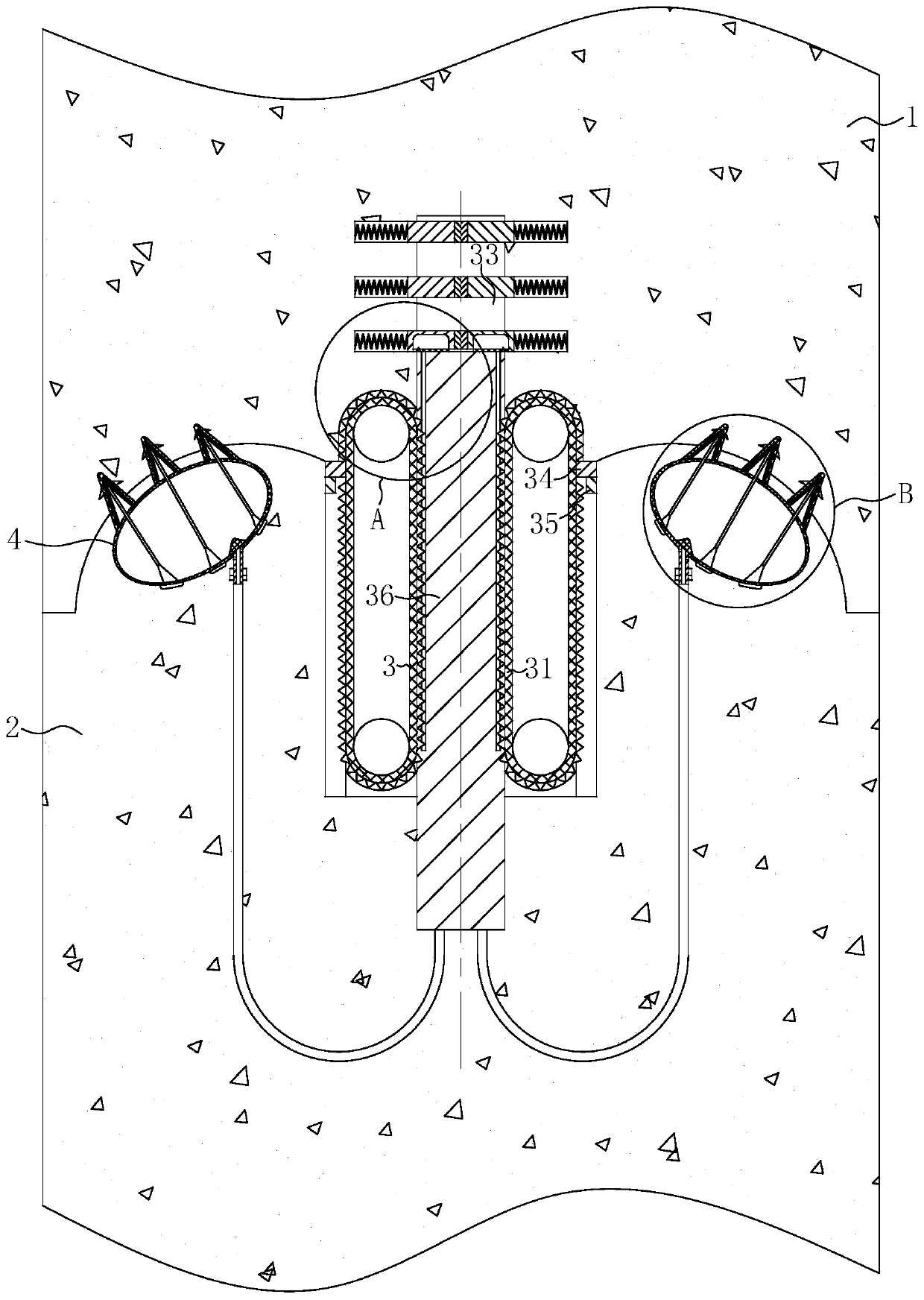

[0018] use Figure 1-Figure 3 A prefabricated reinforced concrete shear wall according to an embodiment of the present invention will be described as follows.

[0019] Such as Figure 1-Figure 3As shown, a prefabricated reinforced concrete shear wall according to the present invention includes No. 1 installation wall 1, No. 2 installation wall 2, plug-in mechanism 3 and sealing connection mechanism 4; said No. 1 installation wall 1 and No. 2 installation wall The junction of the installation wall 2 is an upper arc; the plug-in mechanism 3 is located in the No. 1 installation wall 1, and the plug-in mechanism 3 includes a driving pulley 31, teeth 32, chute 33, No. 1 brake block 34, No. 2 brake block 35 and plug post 36; Described drive pulley 31 is symmetrically fixedly connected with two at the lower end of No. 1 installation wall 1, and the outer surface of drive pulley 31 is fixedly equipped with teeth 32, and the left end of drive pulley 31 is A No. 1 brake block 34 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com