Process method for preparing marine fuel oil on basis of catalytic cracking oil slurry desolidification-hydrogenation

A technology of catalytic cracking oil slurry and process method, which is applied in the deep processing of petroleum products and the high value-added deep processing and utilization field of catalytic cracking oil slurry, can solve the problems of increasing the cost of marine fuel and reducing the profit margin of marine fuel, and achieves low equipment investment, The effect of low carbon residue and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

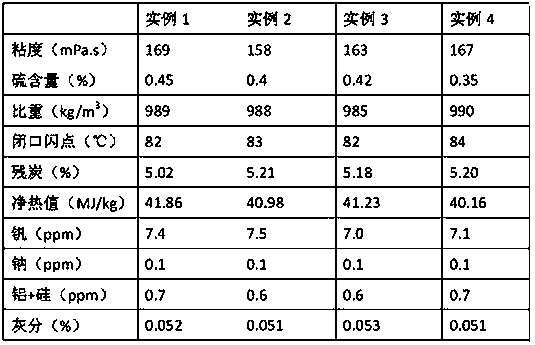

Examples

Embodiment 1

[0028] Mix catalytic cracking oil slurry and petroleum ether at a ratio of 2:1 (mass ratio), and use a laminated centrifuge for centrifugation. The separation factor is 10500, the slagging period is 150min, the slagging time is 0.7s, and the centrifugation temperature is 40°C. Obtain the desolidified mixed oil slurry and discharge the solid residue, the processing capacity is 2t / h.

[0029] The desolidified mixed oil slurry was subjected to flash separation treatment under the conditions of tower top temperature 100°C and tower bottom temperature 170°C to obtain desolidified oil slurry with an ash content of 62ppm and reusable diluent petroleum ether.

[0030] Pass the desolidified oil slurry through a catalyst with nickel oxide and molybdenum oxide as the active component and alumina as the carrier, at a space velocity of 0.25h -1 , catalytic hydrogenation under the conditions of reaction temperature 350°C, reaction pressure 6Mpa, hydrogen oil volume ratio 600:1, to obtain hy...

Embodiment 2

[0033] Mix catalytic cracking oil slurry and toluene at a ratio of 3:1 (mass ratio), and use a laminated centrifuge for centrifugation. The separation factor is 8000, the slagging period is 30 minutes, the slagging time is 0.5s, and the centrifugation temperature is 45°C. Solid mixed oil slurry and discharge solid residue.

[0034] The desolidified mixed oil slurry is subjected to flash treatment under the conditions of tower top temperature 110°C and tower bottom temperature 235°C to obtain desolidified oil slurry with an ash content of 50ppm and reusable diluent catalytic diesel.

[0035] The desolidified oil slurry passes through a catalyst with nickel oxide and molybdenum oxide as the active component and alumina as the carrier, at a space velocity of 0.5h -1 , catalytic hydrogenation under the conditions of reaction temperature 370°C, reaction pressure 8.5Mpa, hydrogen oil volume ratio 630:1, to obtain hydrogenated oil slurry;

[0036] The performance parameters of the p...

Embodiment 3

[0038] Mix catalytic cracking oil slurry and catalytic diesel oil at a ratio of 4:3 (mass ratio), and use a laminated centrifuge for centrifugation. The separation factor is 9800, the slagging period is 60 minutes, the slagging time is 0.4s, and the centrifugation temperature is 60°C. Desolidify the mixed oil slurry and discharge the solid residue.

[0039]The desolidified mixed oil slurry is flashed at the top temperature of 235°C and the bottom temperature of 400°C, and the gas phase of the flashing process is condensed and captured by the condenser, and then refluxed to obtain a desolidified oil with an ash content of 71 ppm slurry and reusable catalytic diesel thinner.

[0040] Pass the desolidified oil slurry through a catalyst with nickel oxide and molybdenum oxide as the active component and alumina as the carrier, at a space velocity of 0.35h -1 , the reaction temperature is 360°C, the reaction pressure is 7Mpa, and the hydrogen-to-oil volume ratio is 638:1. Catalytic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com