Anti-radiation aerated concrete containing lead and zinc tailings

A technology of air-entrained concrete and radiation protection, which is applied in the field of environment and building materials, can solve the problems of unobvious economic benefits and high extraction costs, and achieve the effects of improving radiation protection performance, reducing production costs, and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

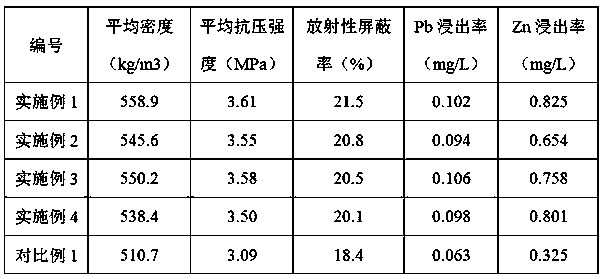

Examples

Embodiment 1

[0021] A radiation-proof aerated concrete containing lead-zinc tailings, comprising the following components by mass percentage: 5% lead-zinc tailings, 5% cement, 10% fine sand, 10% fly ash, and 10% quicklime , gypsum 1% and aluminum powder paste 0.05%.

Embodiment 2

[0023] A radiation-proof aerated concrete containing lead-zinc tailings, comprising the following components by mass percentage: 20% lead-zinc tailings, 15% cement, 40% fine sand, 40% fly ash, and 20% quicklime , gypsum 5% and aluminum powder paste 0.10%.

Embodiment 3

[0025] A radiation-proof aerated concrete containing lead-zinc tailings, comprising the following components by mass percentage: 10% lead-zinc tailings, 10% cement, 20% fine sand, 25% fly ash, and 15% quicklime , gypsum 3% and aluminum powder paste 0.07%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com