Rare earth oxysulfide taken as lubricating oil additive, and preparation method thereof

A technology of lubricating oil additives and rare earth oxides, applied in rare earth metal compounds, additives, lubricating compositions, etc., can solve the problems of unsatisfactory anti-wear effect, easy chemical reaction of compounds, destruction of lubricating effect, etc., to improve lubricating friction Environment, both antioxidant capacity and lubricity, good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides a method for preparing rare earth oxysulfides used as lubricating oil additives. The rare earth oxysulfides have the general formula Ln 2 o 2 S, wherein Ln is a rare earth element, specifically one of La, Ce, Pr, Nd, Gd, Yb, Y and Eu, and the preparation method of rare earth oxysulfide comprises the following steps:

[0040] (1) Weigh the raw material rare earth oxide Ln 2 o 3 Put it into a ball mill, then add the first organic solvent to obtain the first mixture, perform ball milling on the first mixture, and obtain the first slurry after the ball milling is completed; weigh the raw material rare earth sulfide Ln 2 S 3 adding to the first slurry to obtain a second mixture, and performing ball milling on the second mixture to obtain a second slurry;

[0041] In a specific embodiment of the present invention, the rare earth oxide Ln 2 o 3 and rare earth sulfide Ln 2 S 3 The molar ratio is 2:1.

[0042] In a specific embodiment of t...

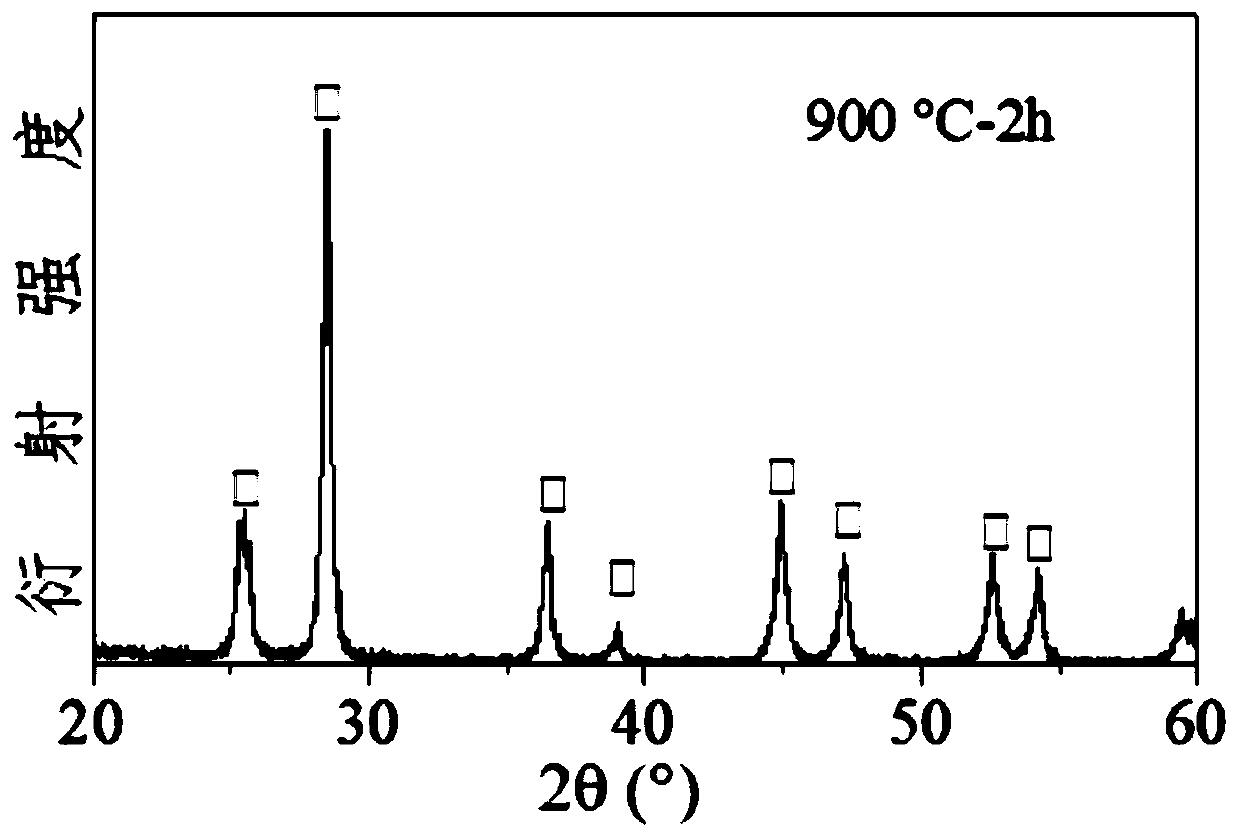

Embodiment 1

[0060] The preparation method of a rare earth oxysulfide as a lubricating oil additive provided in this embodiment comprises the following steps:

[0061] Weigh 6.52g La 2 o 3 Put the coarse particles into the stainless steel ball mill jar, then weigh 50g of stainless steel balls into the ball mill jar, add 150mL of absolute ethanol, then seal the ball mill jar with a sealing gasket and fix it on the planetary ball mill, set the ball mill parameters: speed 2400r / min, ball mill 72h, adjust the direction of forward and reverse every 10 minutes. After ball milling, weigh 3.74g La 2 S 3 Add it into the slurry formed by the above mixture, then set the rotation speed at 300r / min, and ball mill for 3h.

[0062] After ball milling, transfer the above slurry and steel balls to a constant temperature oil bath, set the temperature at 80°C, complete the volatilization of anhydrous ethanol through slow stirring, and then sieve the obtained solid mixture to obtain the initial mixture. ...

Embodiment 2

[0072] The difference between this embodiment and embodiment 1 is that the rare earth oxide La 2 o 3 After ball milling, weigh 3.74g La 2 S 3 and 0.156g Na 2 S was added to the slurry formed by the mixture after rare earth oxide ball milling, and the temperature was raised to 700° C. in a vacuum tube furnace, and the temperature was kept for 2 hours. The other steps were the same as those in Example 1 and will not be repeated here.

[0073] The surface-modified rare earth oxysulfide La prepared in this example 2 o 2 S carried out the same friction test as in Example 1, and after the anti-wear and anti-friction performance test, the surface-modified rare earth oxysulfide La prepared in this example was obtained. 2 o 2 S is used as a lubricating oil additive, and the friction coefficient and wear amount are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com